Laser machining system for carrying out machining process on workpiece by means of laser beam and method for monitoring machining process on workpiece by means of laser beam

A technology of laser processing and processing procedures, which is applied in the direction of spectrometry/spectrophotometry/monochromator, laser welding equipment, metal processing equipment, etc. Problems such as expensive parameterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the following text, the same reference numerals are used for identical or identically acting elements, unless stated otherwise.

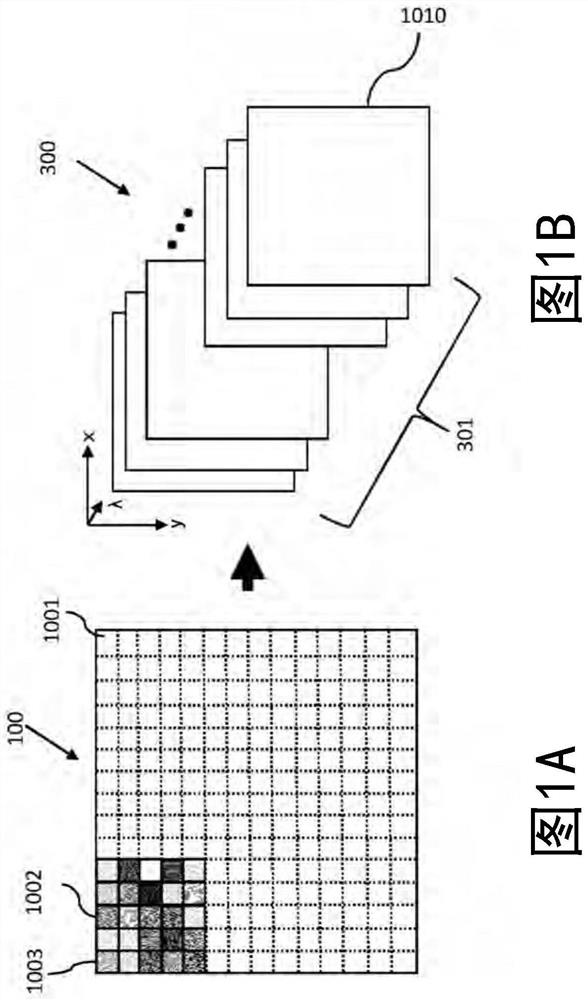

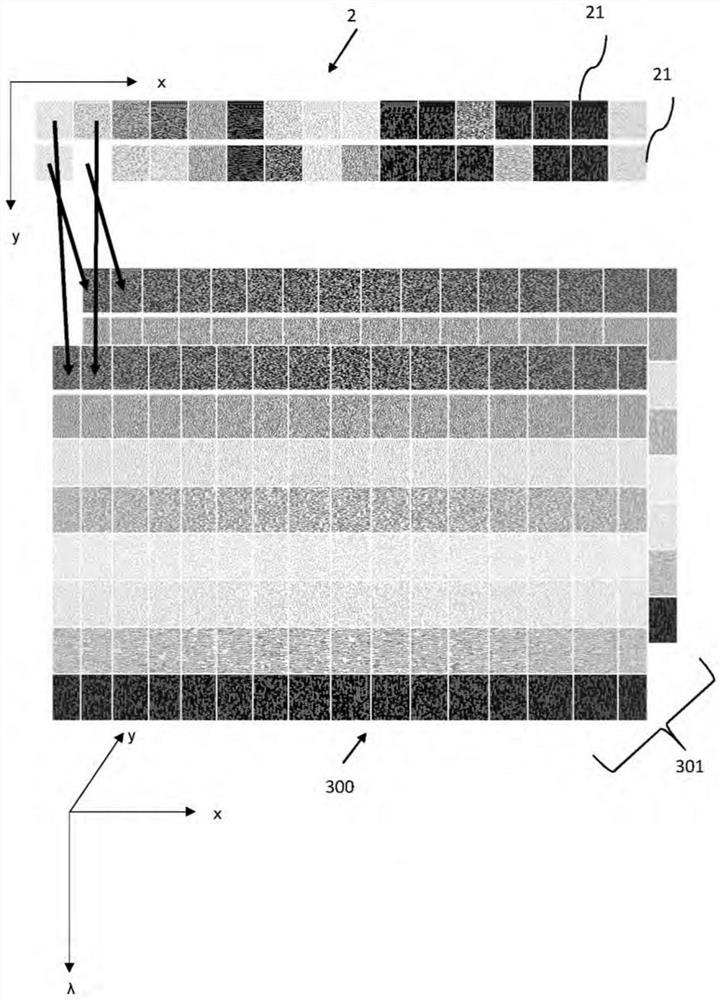

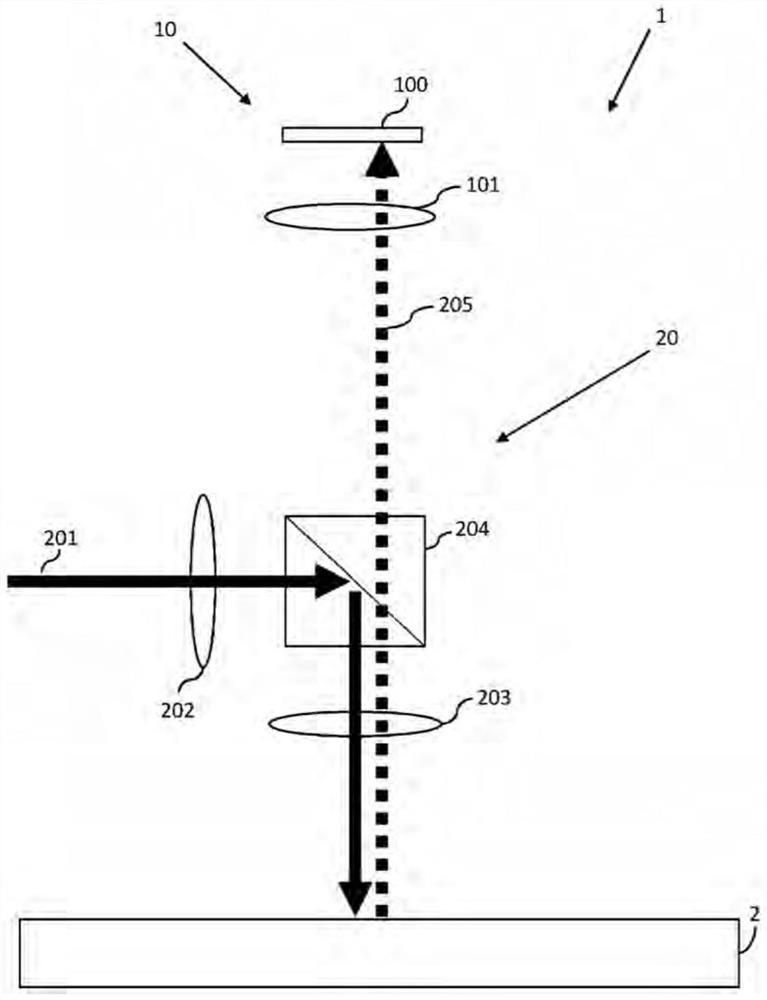

[0054] Figure 1A A schematic diagram showing a hyperspectral sensor according to an embodiment of the disclosure. Figure 1B A schematic diagram showing a hyperspectral image that has been detected by a hyperspectral sensor according to an embodiment of the present disclosure. exist Figure 1A The hyperspectral sensor shown in can be combined with other embodiments of the present disclosure.

[0055] The hyperspectral sensor 100 has a plurality of pixels 1001 arranged along a first direction (x direction or column direction) and a second direction (y direction or row direction) perpendicular to the first direction. These two directions correspond to the two spatial dimensions of the hyperspectral image detected by the hyperspectral sensor 100 . All pixels 1001 of the hyperspectral sensor are able to detect or detect radiation in a certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectral sensitivity | aaaaa | aaaaa |

| spectral sensitivity | aaaaa | aaaaa |

| spectral sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com