Frequency domain enhancement for efficient detection of low SNR flattened residue/stain defects

A defect and flat technology, applied in the field of detection of large residue and stain defects, can solve problems such as increasing the difficulty of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The disclosure has been particularly shown and described with respect to certain embodiments and specific features thereof. The embodiments set forth herein are to be regarded as illustrative and not restrictive. It will be apparent to those skilled in the art that various changes and modifications in form and details can be made without departing from the spirit and scope of the present disclosure. Reference will now be made in detail to the disclosed subject matter which is illustrated in the accompanying drawings.

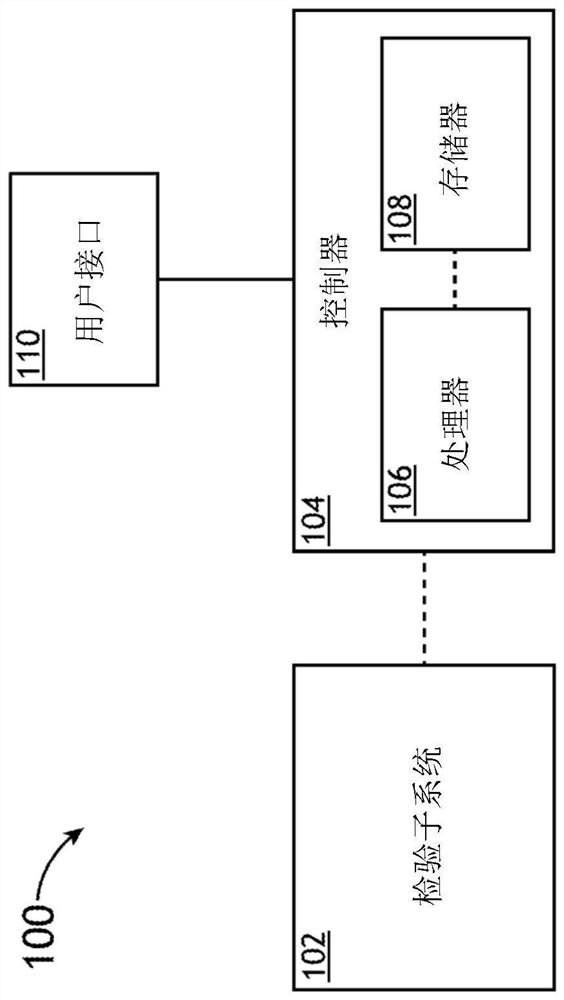

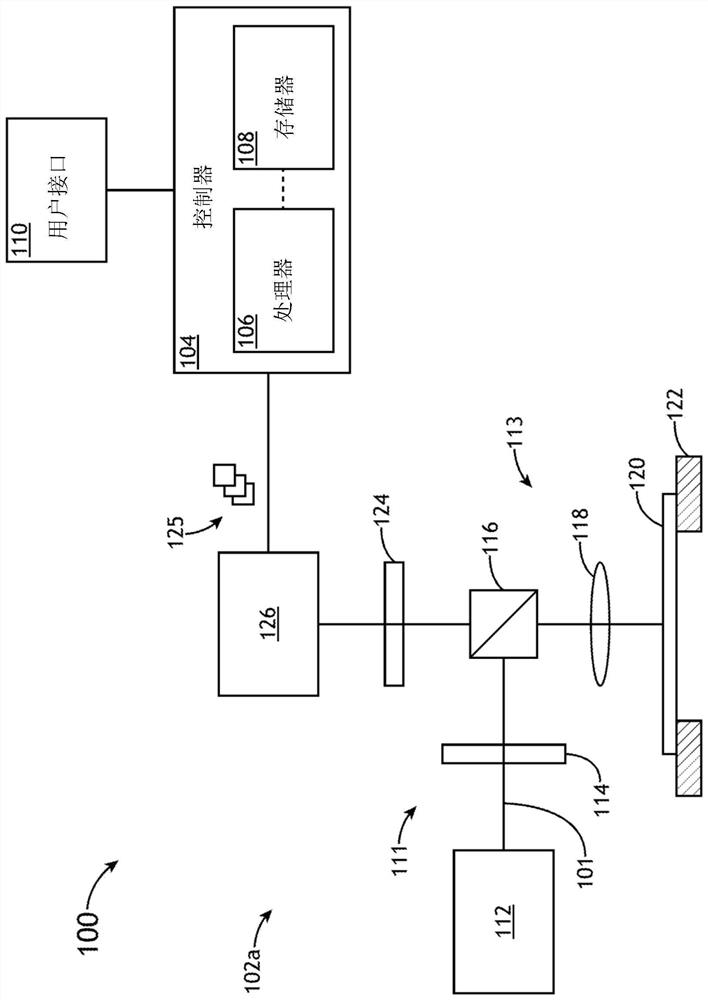

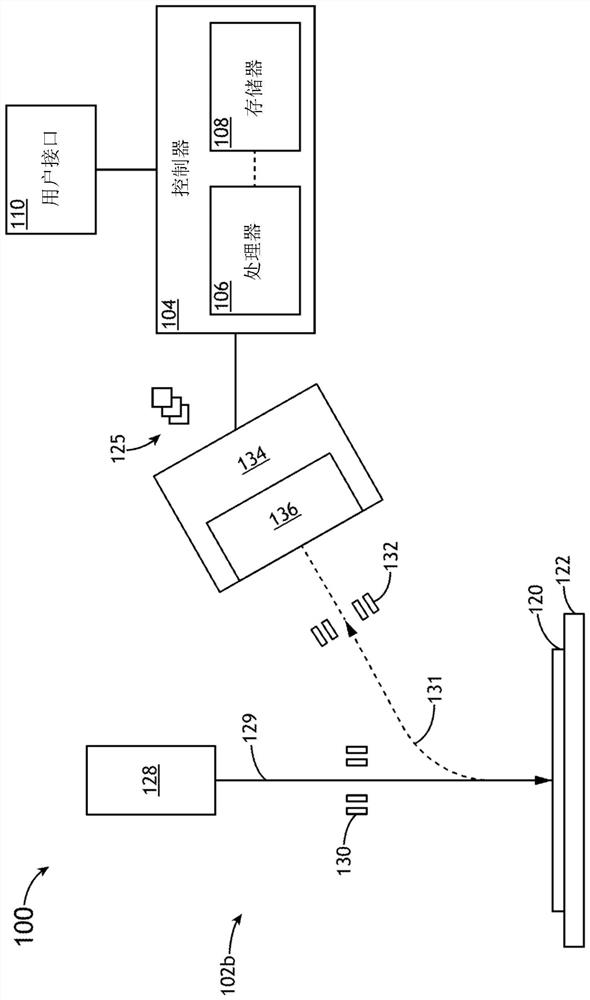

[0020] Embodiments of the present disclosure relate to an inspection system and method. The inspection system can be configured to detect one or more defects on a sample (eg, a semiconductor wafer or a photomask). The system may entail illuminating a sample with photons or electrons and receiving the illumination (eg, photons or electrons reflected and / or scattered from the sample) at one or more detectors to generate image data.

[0021] Image data ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap