Assembly of multi-segment stator

A technology for stators and stator segments, which is used in the manufacture of stator/rotor bodies, electric components, measuring devices, etc., and can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

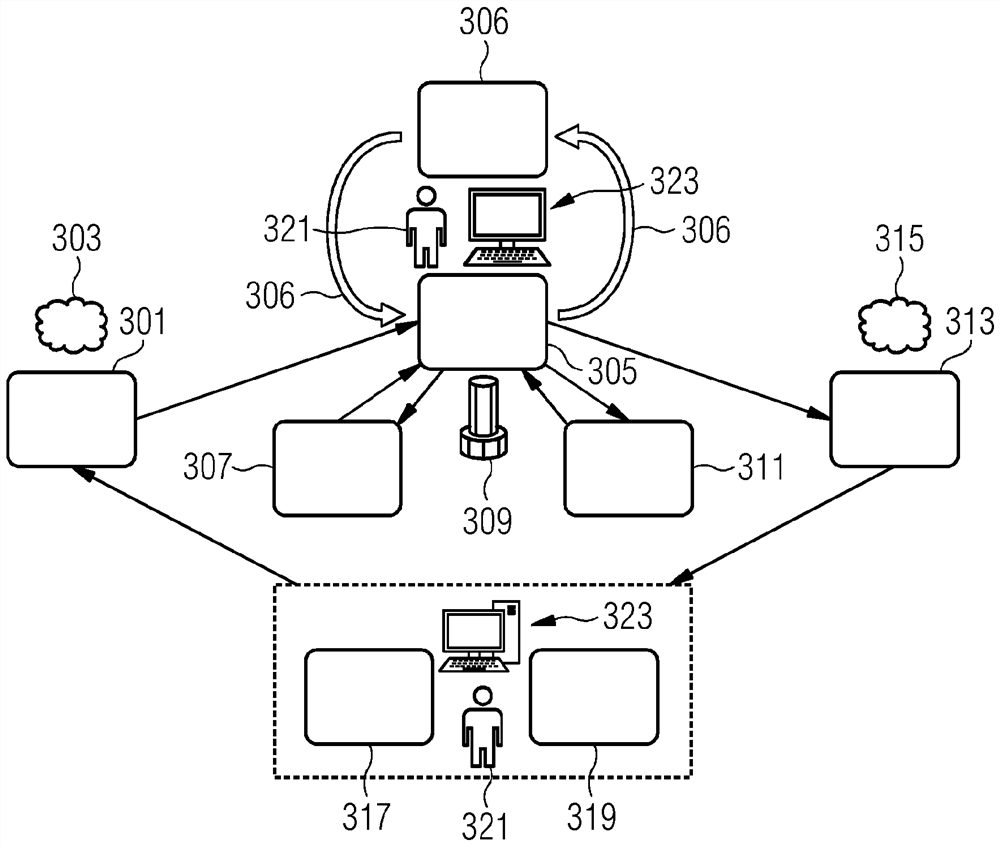

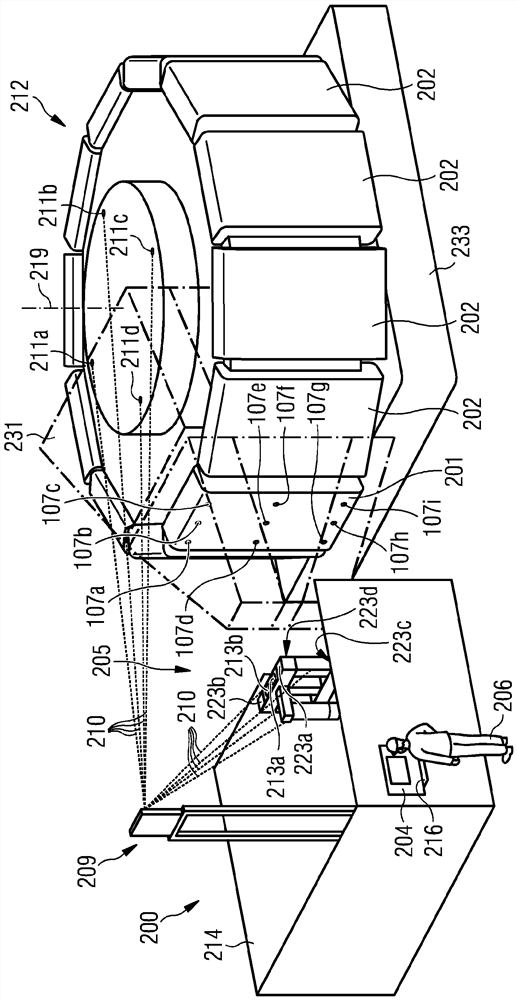

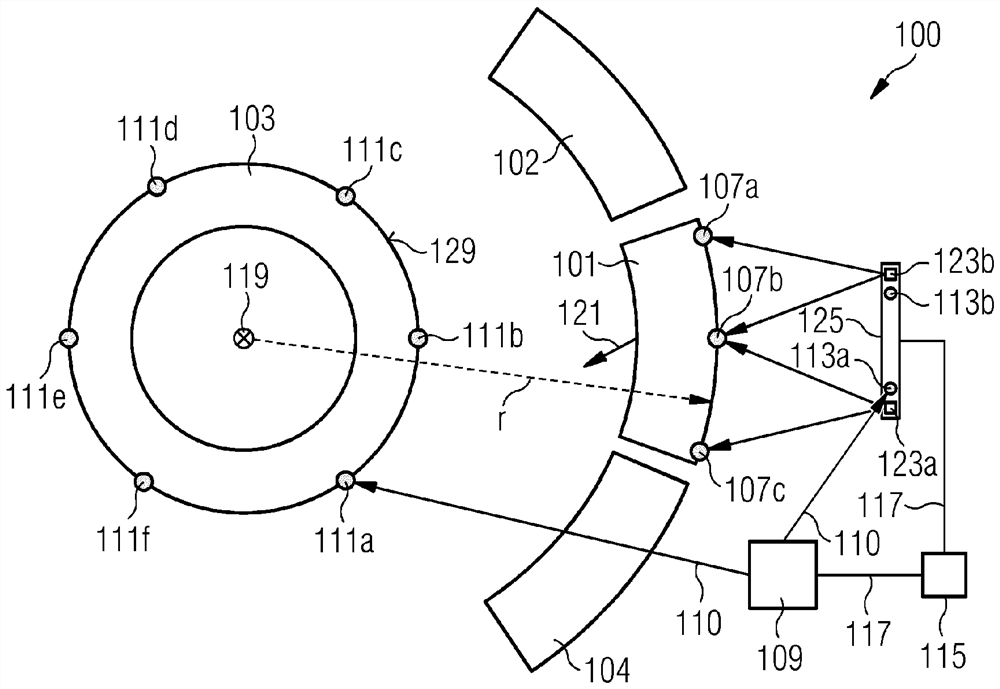

[0044] The illustrations in the figures are in schematic form. Note that in different figures, structurally and / or functionally similar or identical elements are provided with the same reference signs or with reference signs that differ only within the first numeral. A description of an element not described in one embodiment can be taken from a description of that element in another embodiment.

[0045] An arrangement 100 for determining readjustment values in terms of position and / or orientation of a stator segment 101 of an electrical machine (not fully shown) to be assembled with a shaft 103, comprising a camera system 105 configured to To detect the position of a plurality of first reference objects 107a, 107b, 107c attached to the stator segment 101 . The arrangement 100 further comprises a laser tracking system 109 configured to detect the position of a plurality of second reference objects 111 a , . . . , 111 f attached to the shaft 103 . The laser tracking system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com