Stable and efficient disc tool magazine

A disc cutter, high-efficiency technology, used in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of inability to meet processing needs, the capacity of disc cutter magazine is not large, and achieve convenient maintenance or replacement, saving maintenance. cost, the effect of improving environmental quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, and this embodiment does not constitute a limitation to the present invention.

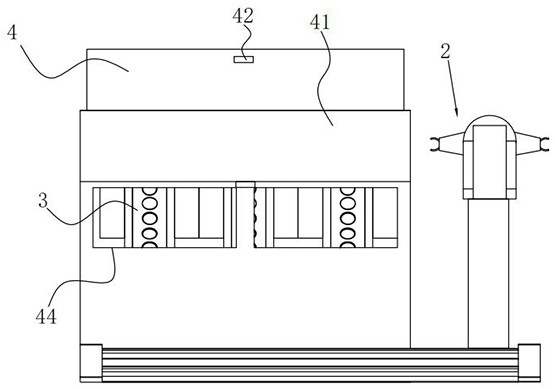

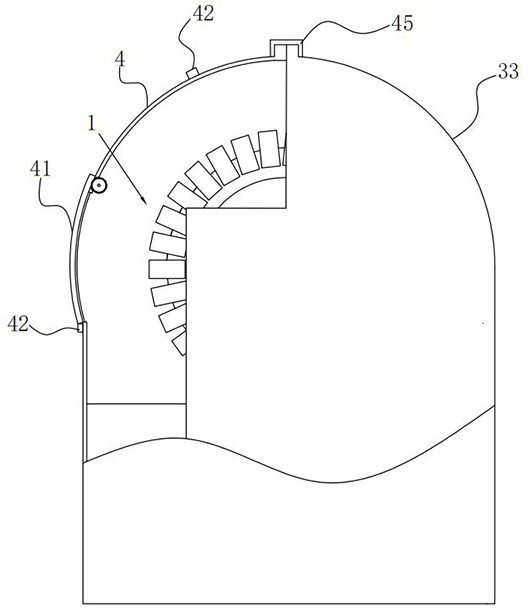

[0024] A stable and efficient disc tool magazine, such as figure 1 and figure 2 As shown, it includes the main body of the tool magazine 1 and the tool changing device 2. The tool changing device 2 is the prior art, and it will not be repeated here. It can be mechanical grippers on both sides, which can be pulled out and rotated after grabbing the tool. The two sides are transposed; the main body of the tool magazine 1 is provided with a protective cover which is arranged outside the knife loading disc 3 to reduce dust and processing waste from entering the interior of the tool magazine.

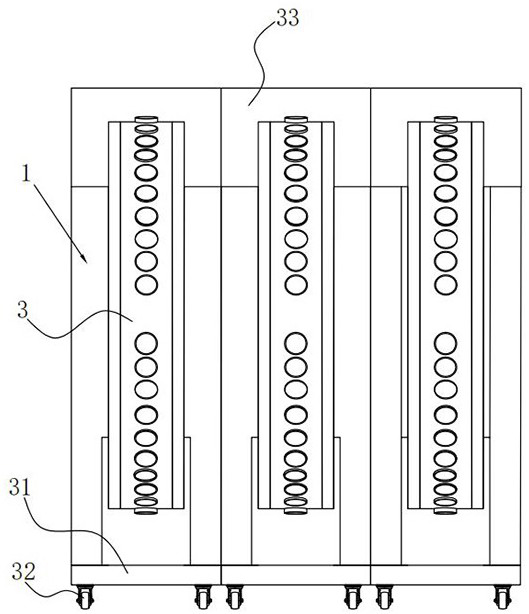

[0025] Such as figure 2 As shown, the main body of the tool magazine 1 includes three tool loading discs 3 arranged side by side. There are several clamping cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com