Plane projection system with auxiliary focusing function and DLP-3D photocuring printing system

A projection system and auxiliary light source technology, applied in the field of 3D printing systems, can solve problems such as high power, affecting printing accuracy, and difficult DLP surface projection application systems, and achieve the effect of clear focusing and meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

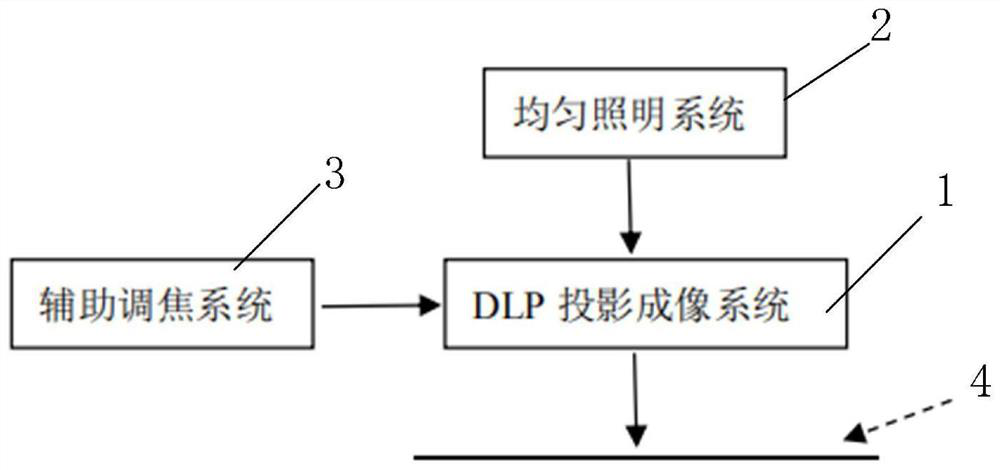

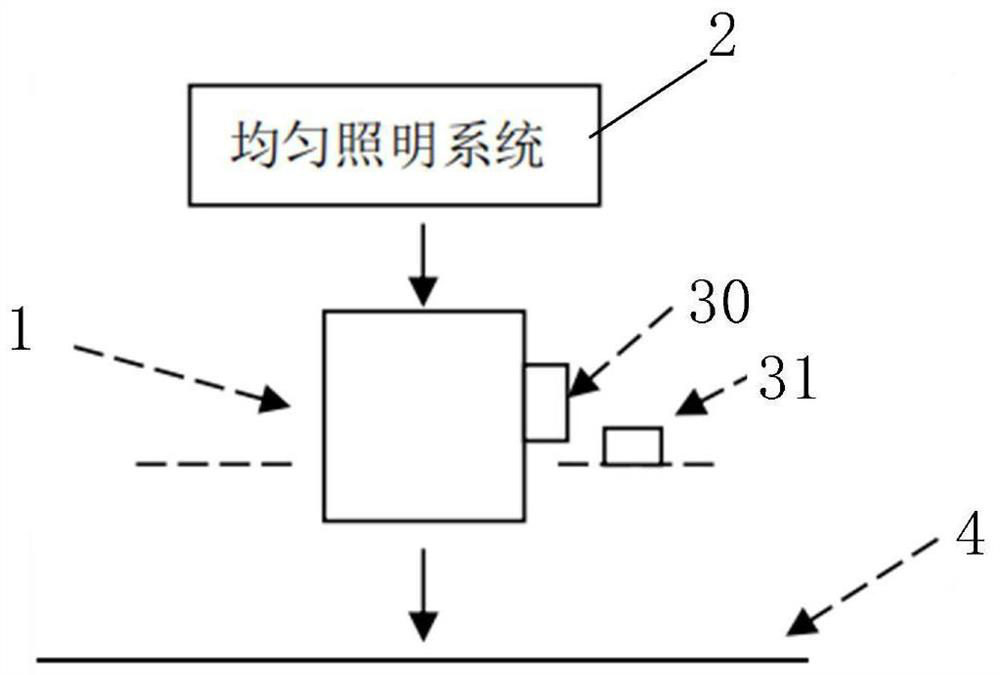

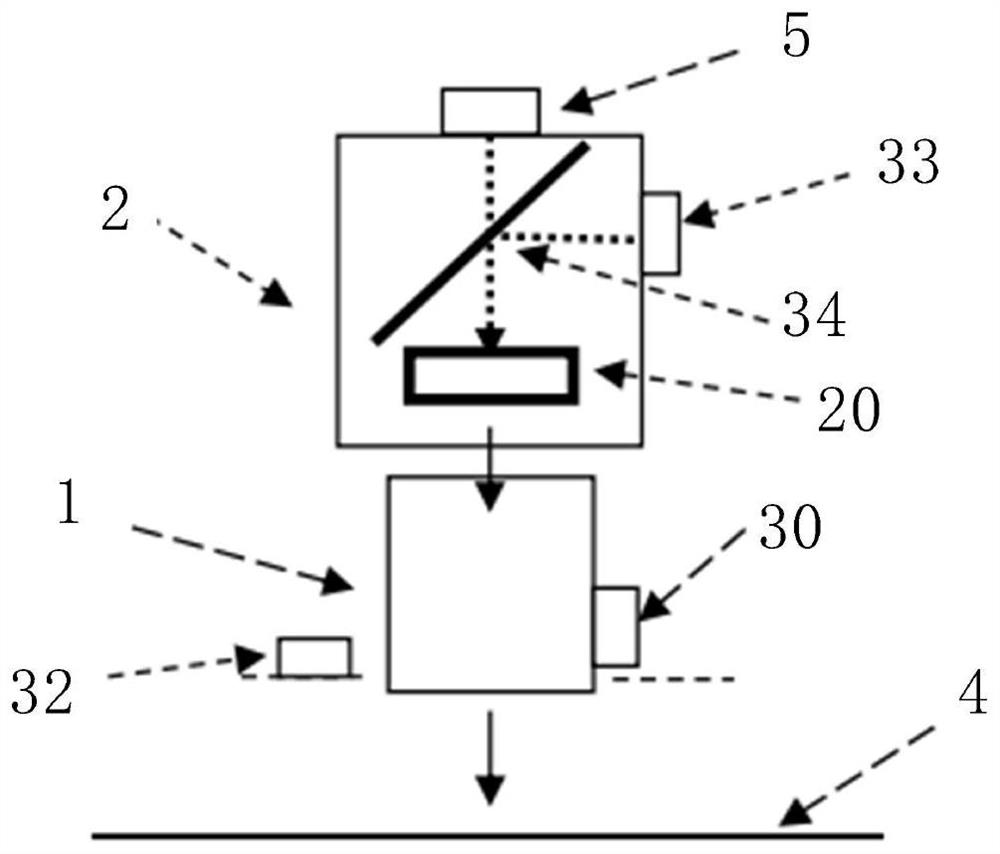

[0022] The invention discloses a surface projection system with an auxiliary focusing function, which combines Figure 1 to Figure 3 As shown, it includes a surface projection imaging system 1, a uniform lighting system 2, an auxiliary focusing system 3 and a main light source 5, the surface projection imaging system 1 is arranged above the projection working surface 4, and the uniform lighting system 2 is used After transmitting the light beam emitted by the main light source 5 to the surface projection imaging system 1, the auxiliary focusing system 3 is used to adjust the focusing mechanism of the surface projection imaging system 1, so that the surface projection imaging system 1 Clear patterns are projected on the projection working surface 4.

[0023] In the above system, the main light source 5, the uniform lighting system 2 and the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap