Vehicle panel emitting light in three-dimensional gradient pattern

A technology of three-dimensional patterns and panels, applied in the production of light strips, road vehicles, vehicle parts, etc., can solve the problems of poor three-dimensional effect and low visibility, achieve cost saving, improve three-dimensional effect, and make up for the effect of low luxury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

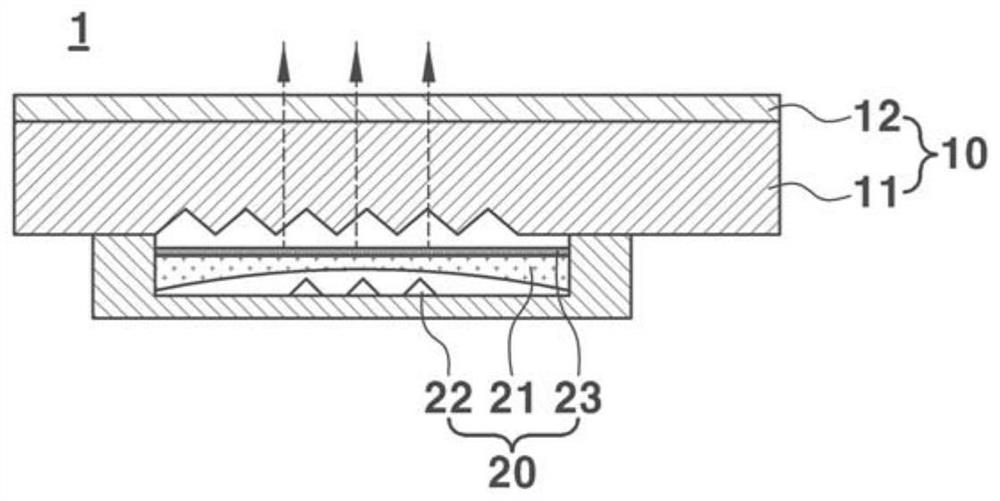

Method used

Image

Examples

Embodiment 1-1-1

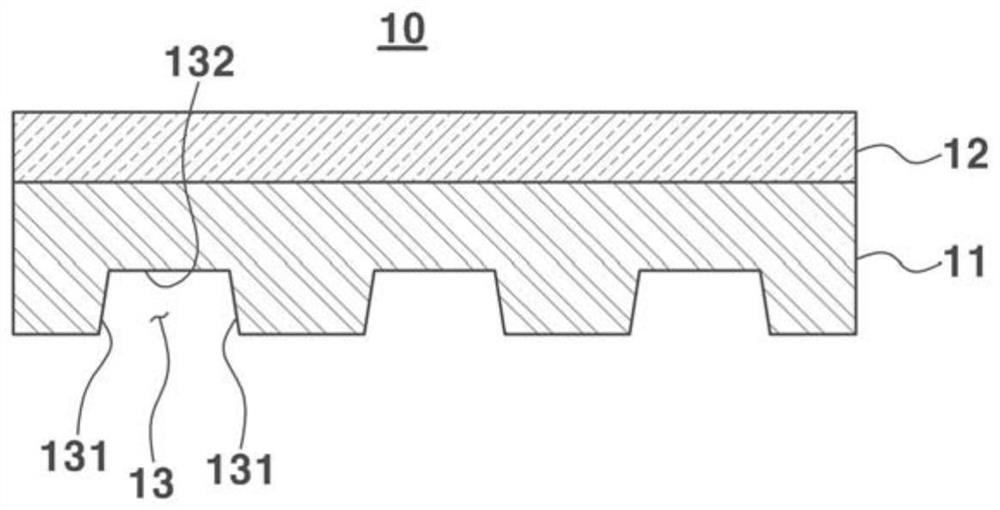

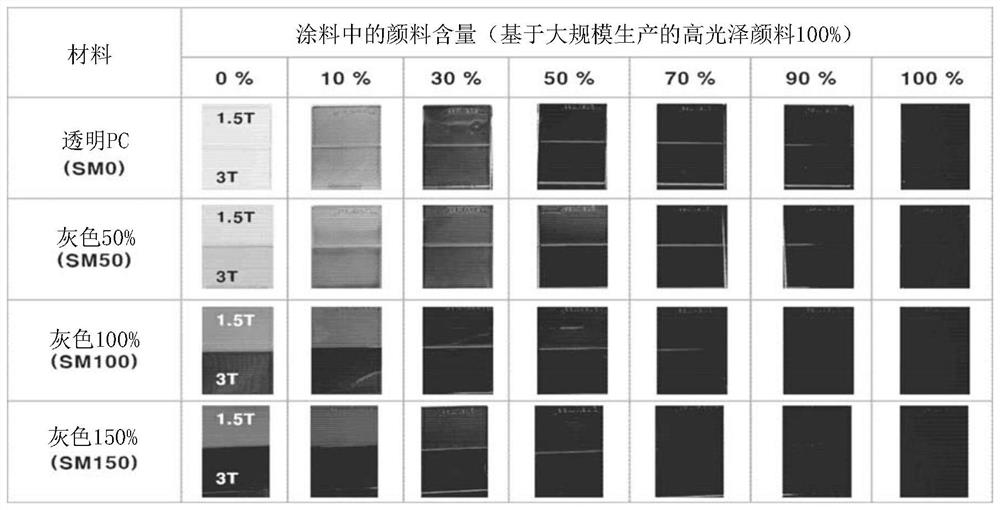

[0090] (Three-dimensional pattern part) An opaque carbon dioxide containing 99.994% by weight of polycarbonate and 0.006% by weight of a carbon black-containing pigment was produced by mixing polycarbonate (PC) as a base material and a carbon black-containing pigment using a twin-screw extruder. Esters (gray 100%; SM100). At this time, the three-dimensional pattern part is composed of a plurality of unit parts with a thickness of 3.0 mm, and the shape of the three-dimensional pattern contained in the three-dimensional pattern part has a rhombus bottom surface, and the engraving depth is 0.2 mm to 0.8 mm.

[0091] (Coating part) A coating part is manufactured by mixing a light-transmitting black high-gloss paint as a colorless paint, and carbon black, an azo compound, and a phthalocyanine compound as a pigment, and then the manufactured coating part is exposed to UV light. The photocurable type is coated on the upper surface of the manufactured three-dimensional pattern portion...

Embodiment 1-1-2 and Embodiment 1-1-3

[0096] Compared with Example 1-1-1, a vehicle panel was produced in the same manner as in Example 1-1-1, except that the coating portion was produced with a thickness of 10 μm to 11 μm (50%), thereby producing a coating containing 2.5 % of the pigment coating part (Example 1-1-2), or to produce a coating part with a thickness of 14 μm to 15 μm (70%), thereby producing a coating part containing 3.5% of the pigment (Example 1-1 -3).

Embodiment 1-2-1 to Embodiment 1-2-3

[0098]Compared with Example 1-1-1 to Example 1-1-3, the vehicle panel was manufactured in the same manner as in Example 1-1-1 to Example 1-1-3, except that the 1.5mm A thickness of 3.0mm instead of a thickness of 3.0mm produces a three-dimensional pattern part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com