Underground expansion plugging mechanism

A technology of expansion pipe and expansion block, which is applied in the field of downhole expansion and plugging mechanism, can solve the problems of limited expansion coefficient and inability to adapt, and achieve the effects of controllable expansion diameter, wide application range and ensuring formation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

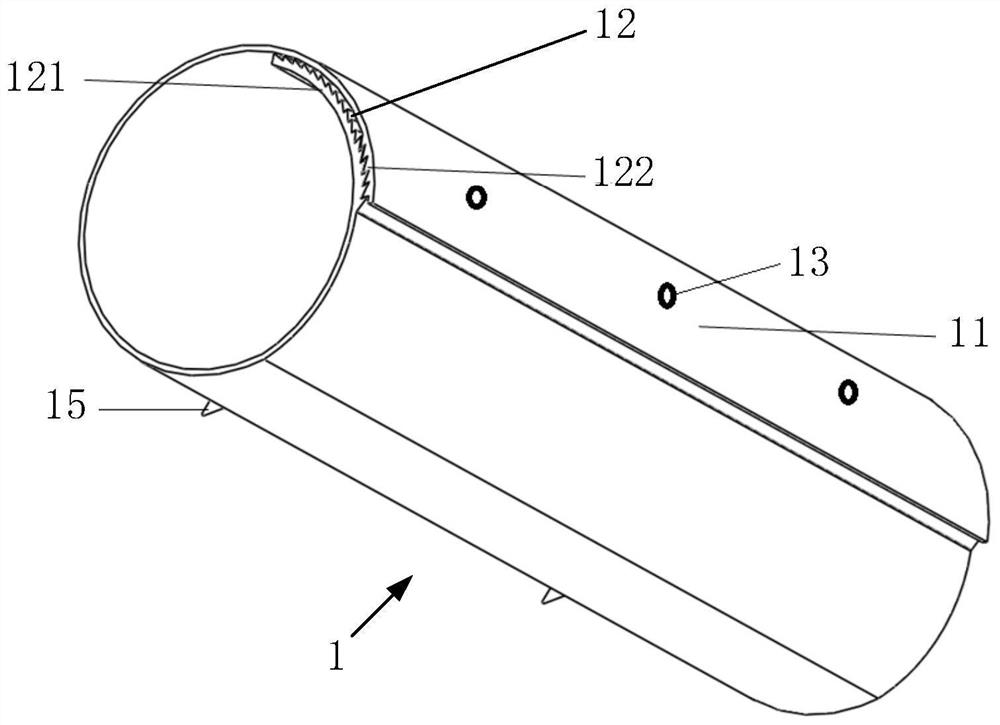

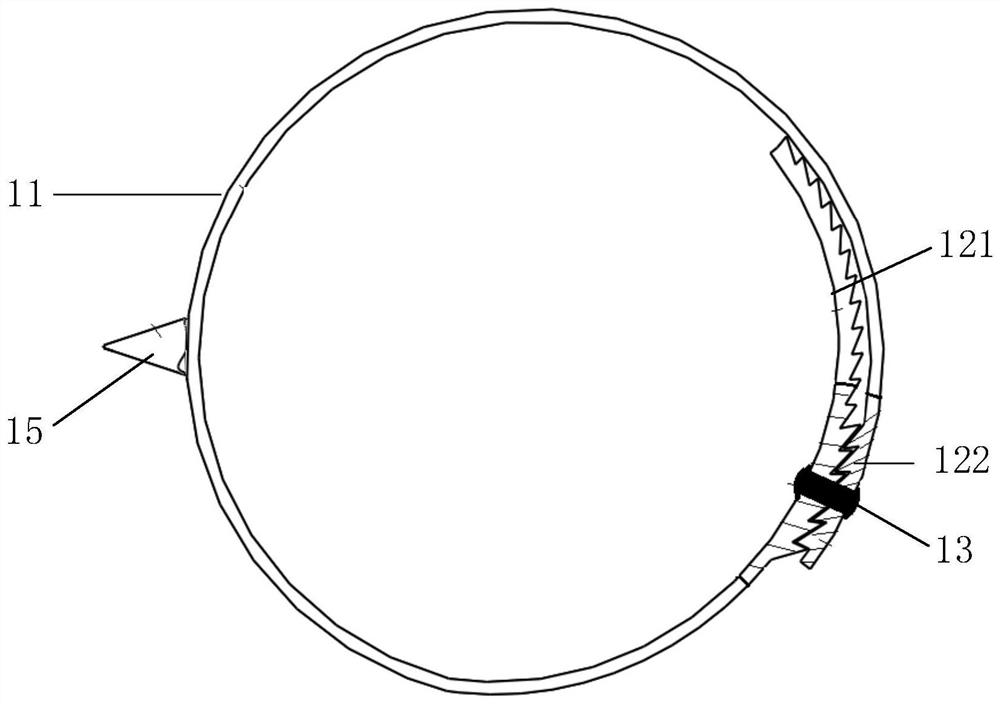

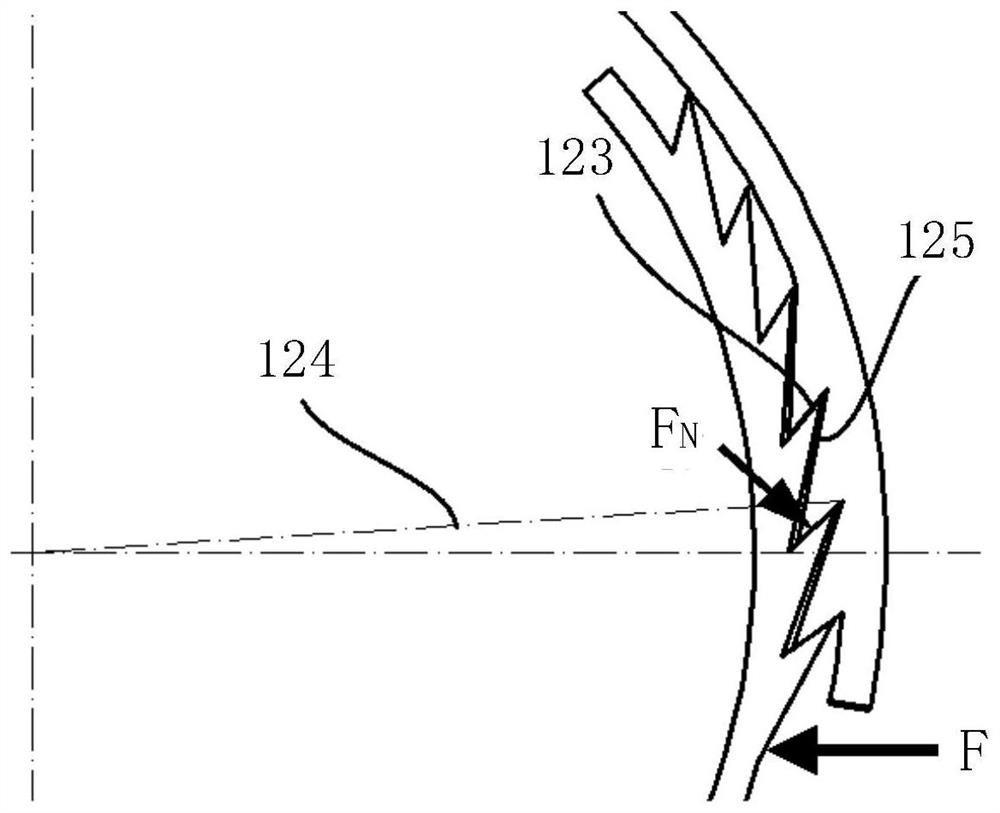

[0033] Such as Figure 1 to Figure 3 As shown, the downhole expansion plugging mechanism of this embodiment includes an outer expansion assembly 1 and an inner expansion assembly 2 . The inner expansion component 2 is arranged in the outer expansion component 1 to provide the expansion force of the outer expansion component 1 . The external expansion assembly 1 includes a coiled tubular body 11, an engaging part 12 and a tubular positioning member 13, wherein the coiled tubular body 11 is an expandable coiled tubular body 11, and the coiled tubular body 11 is made of a steel plate The overlapping parts of the coiled tube body 11 are engaged with each other through the engaging part 12, and the internal meshing angle of the engaging part 12 is set towards the moving direction of the outer ring of the coiled tube body 11. While the winding pipe body 11 is effectively expanded, it can effectively prevent the winding pipe body 11 from retreating after expansion; the pipe body pos...

Embodiment 2

[0049] Figure 5 It shows another embodiment of the downhole expansion plugging mechanism of the present invention. This embodiment is basically the same as Embodiment 1, the difference is that the external expansion assembly 1 of this embodiment also includes an external expansion tube 14, and the external expansion tube 14 is set There is an expansion opening 141 to provide expansion space for the outer expansion tube 14 . The outer expansion tube 14 is wrapped on the outer side of the coiled tube body 11 , and the combination of the outer expansion tube 14 and the coiled tube body 11 further improves the crush resistance of the coiled tube body 11 . At the same time, the positioning cones 15 are arranged on the outer wall of the outer expansion tube 14 , and a plurality of positioning cones 15 are arranged in a straight line along the length direction of the coiled tube body 11 .

[0050] In this embodiment, the expansion openings 141 of the external expansion tube 14 are ...

Embodiment 3

[0054] Figure 7 It shows another embodiment of the downhole expansion and plugging mechanism of the present invention. This embodiment is basically the same as Embodiment 2, the difference is that an expansion gap is left at the position of the expansion opening 141 of the outer expansion tube 14 of this example, and the expansion gap is the same as The engaging parts 12 located at the position of the coiled tubular body 11 are oppositely arranged. It enables the downhole expansion and sealing mechanism to expand evenly, and the outer expansion tube 14 can be closely attached to the casing to be repaired or the well wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com