Diesel engine oil nozzle pipeline electric heating jacket and preparation method thereof

An electric heating jacket and fuel injector technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of lack of heating and the failure of normal fuel injection to start the diesel engine, so as to achieve convenient operation, save power and ensure normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

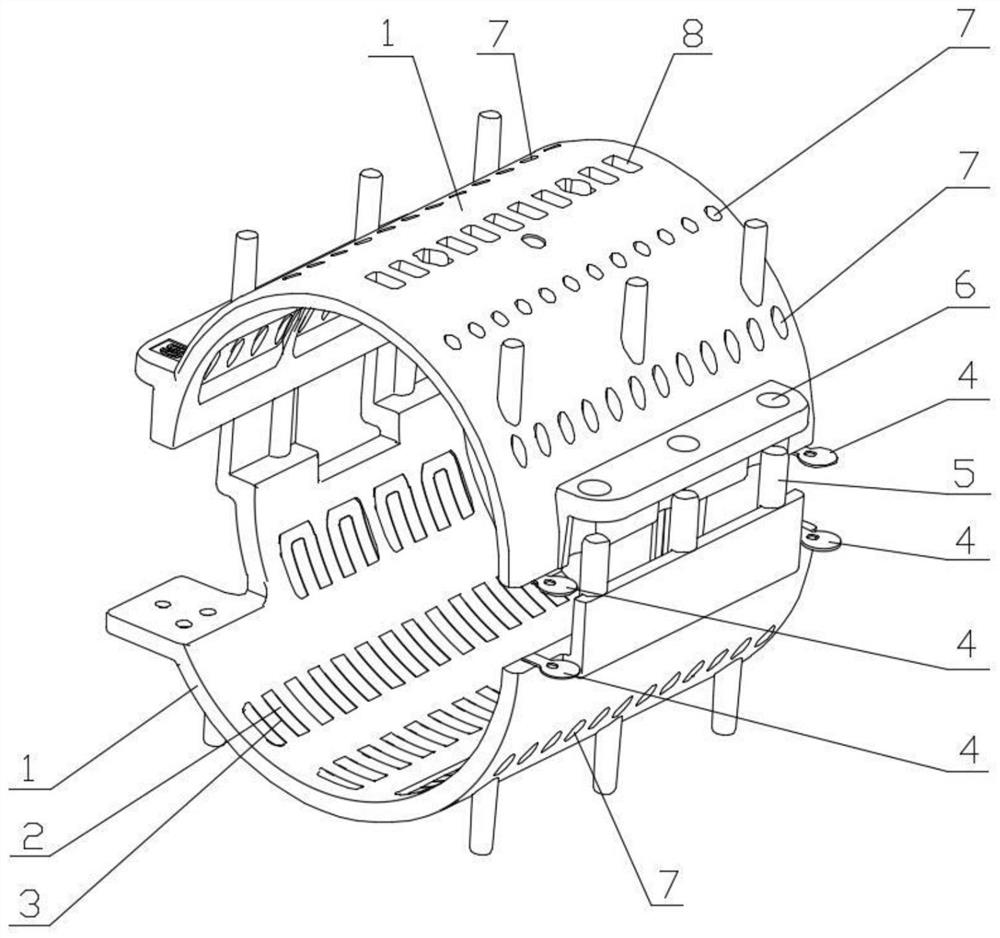

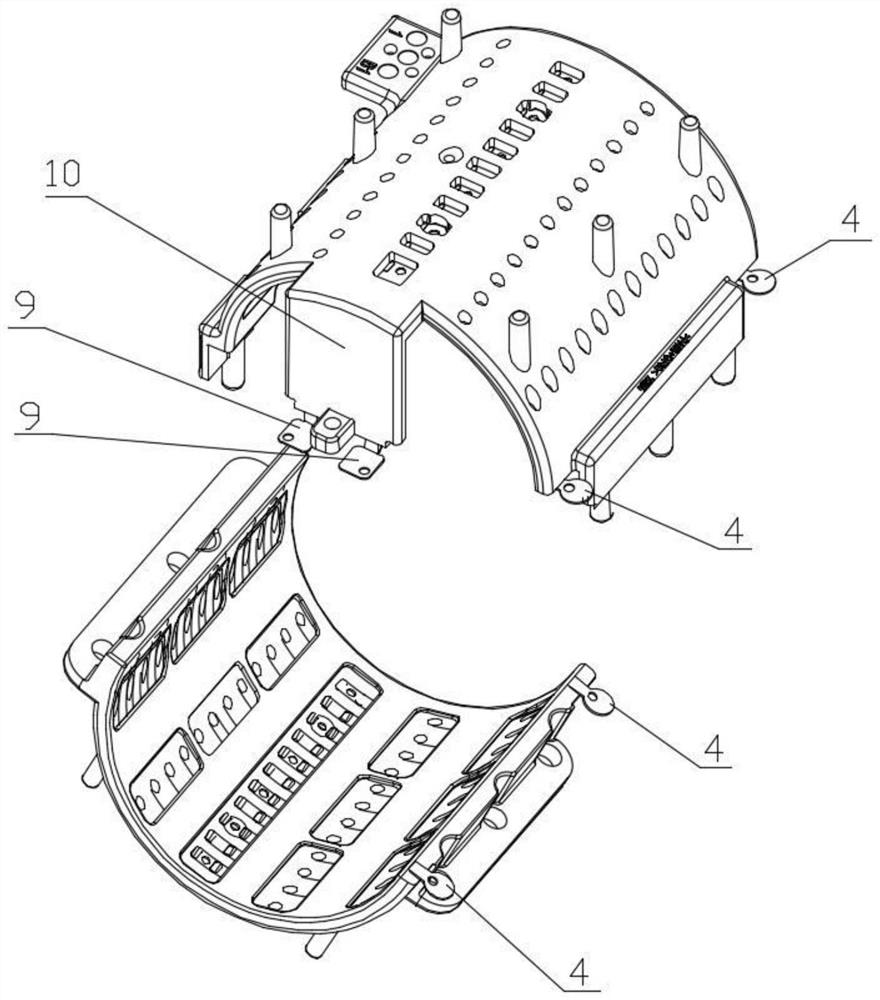

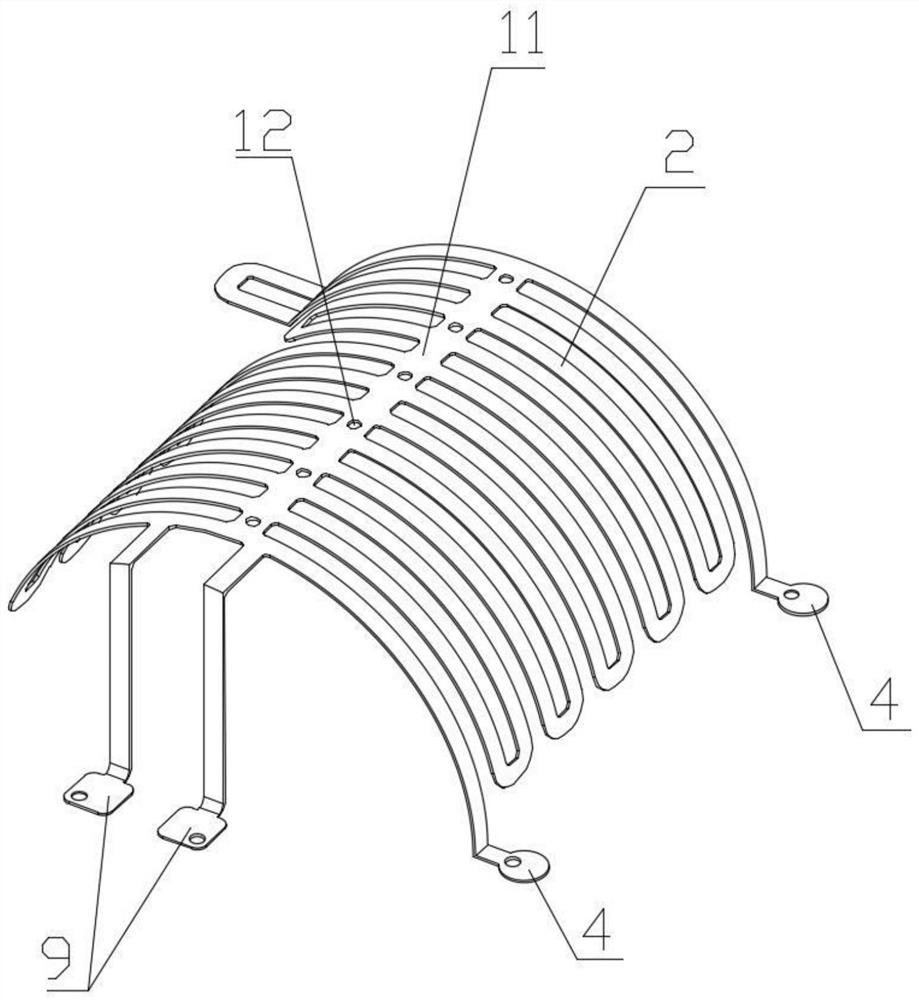

[0029] A kind of diesel engine fuel injector pipeline electric heating jacket of the present invention and the preparation method of the diesel engine fuel injector pipeline electric heating jacket are described respectively below:

[0030] An electric heating jacket for fuel injector pipeline of diesel engine

[0031] Such as figure 1 and figure 2 As shown, an electric heating jacket for a fuel injector pipeline of a diesel engine in this embodiment is a split type, comprising two semicircular tubes 1 injection-molded with insulating nylon material. The sides of the two semicircular tubes 1 are all provided with flanging, and the flanging on one of the semicircular tubes 1 is provided with a first positioning hole 6, and the flanging of the other semicircular tube 1 is provided with a positioning column 5, that is, through positioning The plug-in connection between the column 5 and the first positioning hole 6 positions the plug-in connection state of the two semi-circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com