Temperature control type radiation cold screen device for heat dissipation of light inlet of large-aperture optical remote sensor

A technology of optical remote sensor and light entrance, which is applied in optics, optical components, instruments, etc., can solve problems such as heat accumulation and temperature instability, and achieve the effects of improving service life and imaging quality, high reliability, and improving imaging quality

Pending Publication Date: 2022-05-17

BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the deficiencies of the existing technology, a temperature-controlled radiation cold screen device for heat dissipation at the light entrance of a large-calibe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

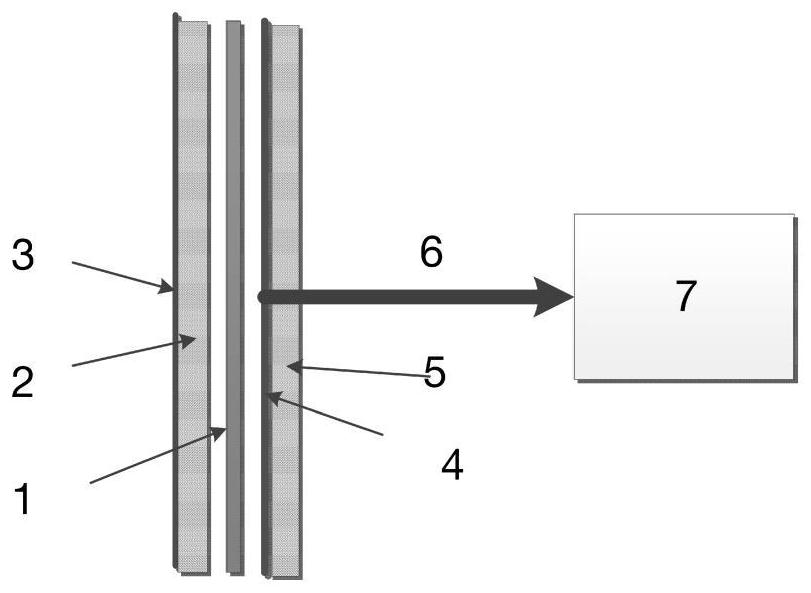

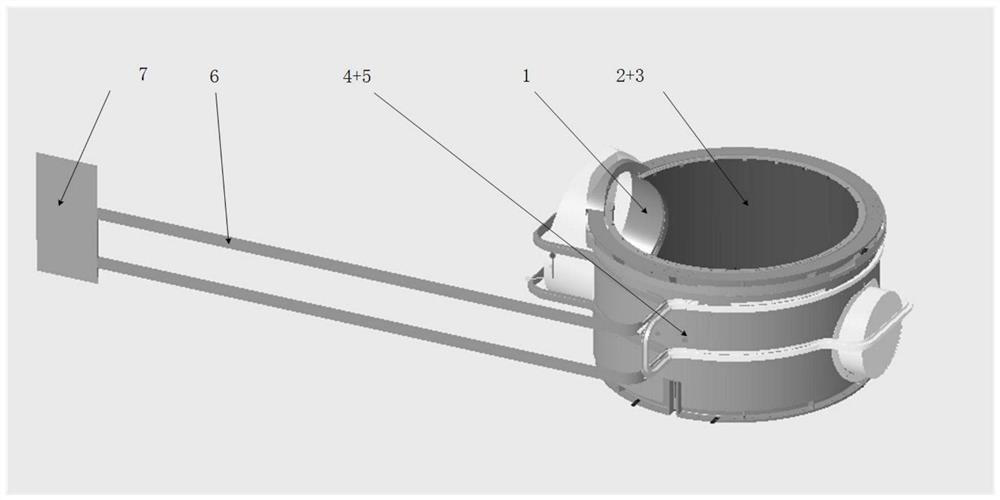

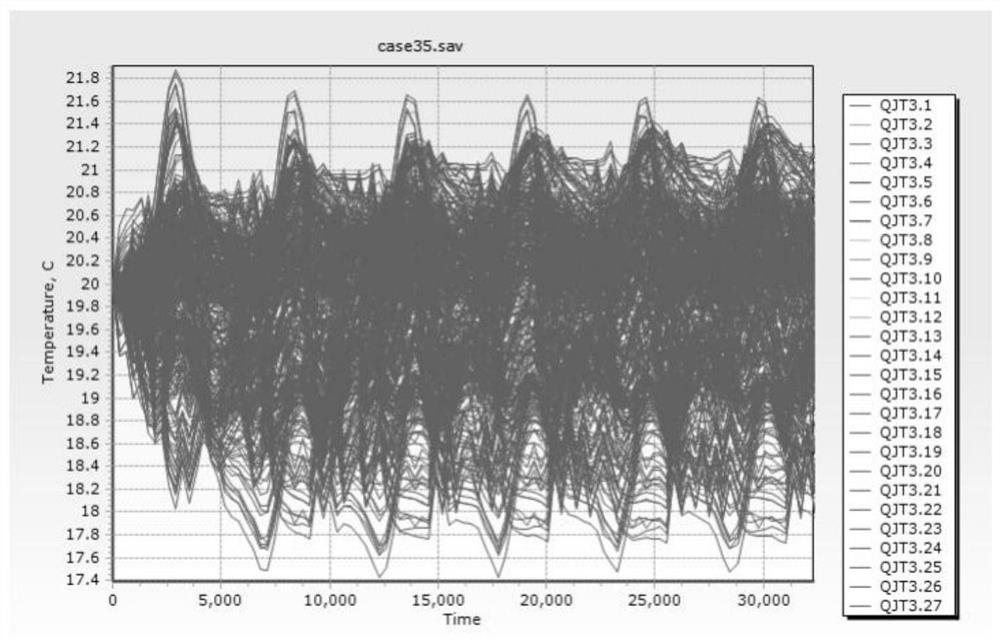

The invention relates to the technical field of heat dissipation structures, and discloses a temperature control type radiation cold shield device for heat dissipation of a light inlet of a large-aperture optical remote sensor, and the device comprises an inner multi-layer heat insulation assembly, an inner heat cover for isolating heat flow disturbance, and an outer heat cover which is disposed at the outer side of a front lens cone and is used for isolating heat flow disturbance, and the inner multi-layer heat insulation assembly and the inner heat cover are successively disposed at the inner side of the front lens cone. The outer heat cover is wrapped with an outer multi-layer heat insulation assembly to reduce heat leakage of the external environment, the outer heat cover is provided with a heat dissipation device used for dissipating heat, the heat dissipation device comprises a heat pipe and a heat dissipation face, the heat pipe is attached to the outer surface of the outer heat cover, and the heat pipe is communicated with the heat dissipation face and used for uniformizing the temperature of the outer heat cover and dissipating heat. And the outer heat cover, the inner heat cover and the front lens cone are all provided with temperature control loops, so that the heat of the light inlet of the large-aperture optical remote sensor can be efficiently dissipated, the temperature of the light inlet can be kept stable, and the precise temperature control of the front lens cone is realized.

Description

technical field [0001] The application relates to the technical field of heat dissipation structures, in particular to a temperature-controlling radiation cold shield device for heat dissipation at the light entrance of a large-diameter optical remote sensor. Background technique [0002] The external heat flow of the optical remote sensor is complex and changeable with the change of orbit and attitude. When the external heat flow of the light entrance is large, the heat absorbed by the light entrance will be greater than the heat dissipated, so that the heat will continue to accumulate, and the temperature of the remote sensor will be unstable. It affects the imaging quality of the optical components, so the optical components need to dissipate heat to ensure that each component works at a normal temperature. Due to the larger aperture, the large-aperture optical remote sensor is more severely affected by the external heat flow, and the demand for heat dissipation is strong...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02B7/00

CPCG02B7/008

Inventor 赵慧于峰赵振明赵宇靳利锋高娟宋欣阳鲁盼孔庆乐连新昊阳明夏晨辉张煚冯磊孙文涛

Owner BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com