Supported Pd catalyst for directly synthesizing hydrogen peroxide and preparation method thereof

A hydrogen peroxide, supported technology, which is applied to the supported Pd catalyst for directly synthesizing hydrogen peroxide and the field of preparation thereof, can solve the problems of high production cost, large environmental pollution, complicated production process and the like, and achieves inhibition of hydrogen peroxide degradation. Side reactions, uniform size and good particle dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] As one aspect of the present invention, a kind of preparation method of the supported Pd catalyst of the present invention directly synthesizes hydrogen peroxide, comprises the steps:

[0037] 1) Dissolving the Pd precursor in deionized water to form a metal precursor solution;

[0038] 2) dissolving the carrier powder in deionized water to form a carrier suspension;

[0039] 3) ultrasonically disperse the metal precursor solution and the carrier suspension, and fully stir them evenly;

[0040] 4) Adding the carrier suspension liquid dropwise to the metal precursor solution, stirring, so that the metal precursor is evenly loaded on the carrier to obtain an impregnation solution;

[0041] 5) Separating the impregnating liquid, vacuum-drying it, and grinding it into powder;

[0042] 6) Calcining the ground powder in static air, and then cooling to room temperature to obtain a supported monometallic Pd catalyst.

[0043] In some embodiments, in step 1), the Pd precursor...

Embodiment 1

[0053] A kind of preparation method of the supported Pd catalyst of directly synthesizing hydrogen peroxide, comprises the steps:

[0054] 1) Weigh 67mgPd(NO 3 ) 2 2H 2 O was dissolved in an appropriate amount of deionized water, and ultrasonicated for 5 minutes to obtain a metal salt solution;

[0055] 2) Weigh 475mgTiO 2 Disperse in an appropriate amount of deionized water, and sonicate for 5 minutes to obtain a carrier suspension;

[0056] 3) During the stirring process, the carrier suspension is added drop by drop into the metal salt solution, and fully stirred so that it is evenly loaded on the carrier to obtain an impregnating solution;

[0057] 4) Put the impregnating solution in a water bath, gradually raise the temperature to 80°C while stirring, heat and evaporate the deionized water until the impregnating solution becomes a viscous paste, cool to room temperature; then place it in a vacuum drying oven for drying , dried at 110°C for 16 hours, and then ground in...

Embodiment 2

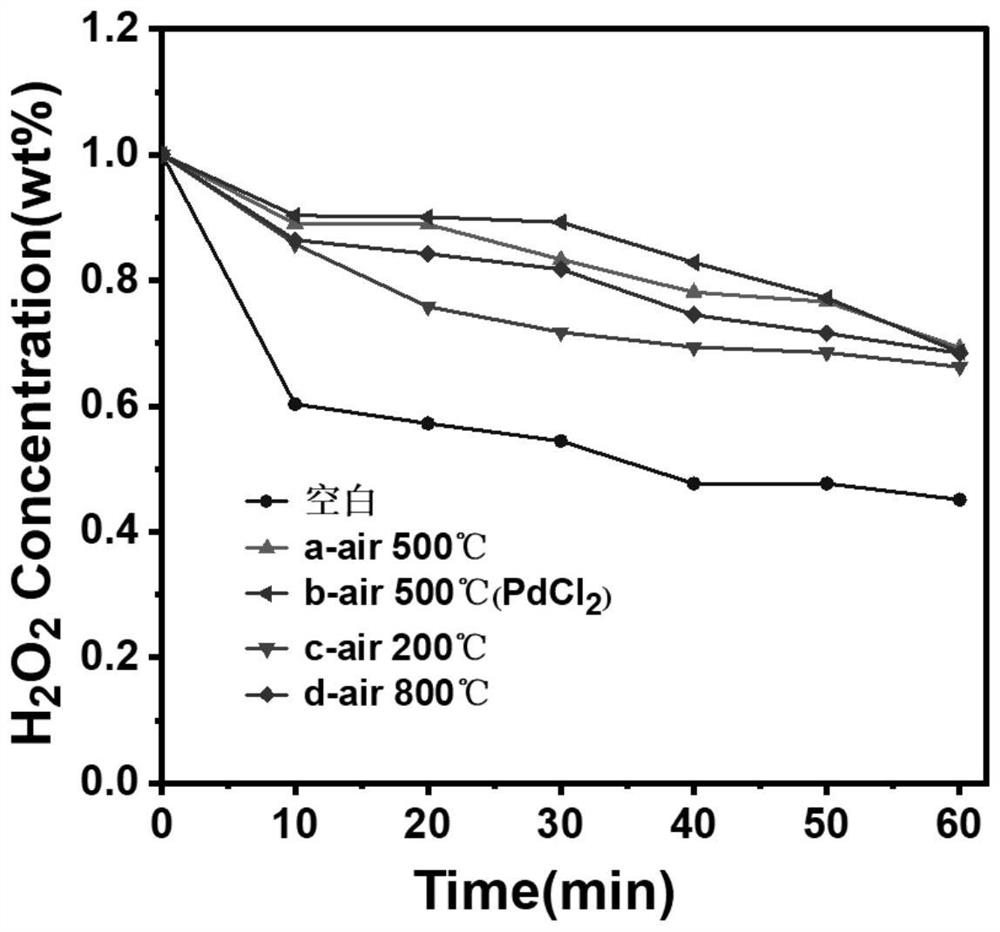

[0064] Repeat Example 1, the difference is only: the Pd precursor uses PdCl 2 Replace Pd(NO 3 ) 2 2H 2 O, the obtained sample is similar to Example 1, with the presence of Pd nanoparticles. figure 1 Among them, b is the pair of H for this embodiment 2 o 2 The degradation situation, still can be for H 2 o 2 Degradation is inhibited.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap