Crane

A crane and boom technology, which is applied to cranes, clockwork mechanisms, hoisting devices, etc., can solve the problems of low operation efficiency, twisted steel strands, large tower cranes affecting construction efficiency, etc., to reduce construction costs, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

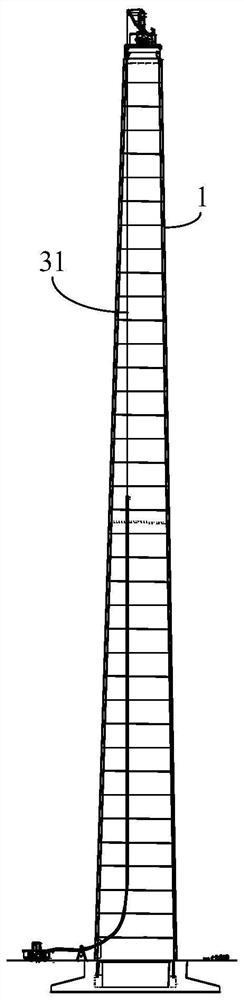

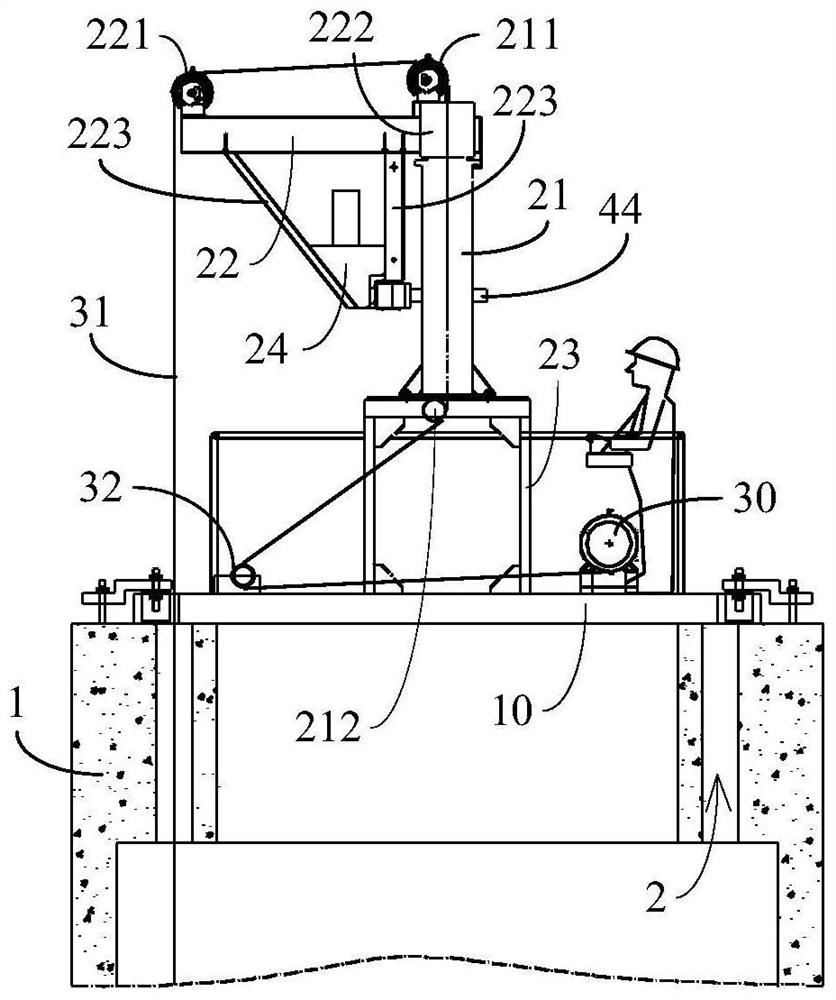

[0018] A crane, the base 10 has a column 21 vertically arranged, the upper end of the column 21 is connected with a boom 22 extending in a cantilever shape, the boom 22 rotates around the axis of the column 21, a winch 30 is arranged on the base 10, and is wound on the winch 30 After the traction rope 31 on the bobbin is drawn out, it is arranged to be suspended from bottom to top along the column 21, along the suspension arm 22 from inside to outside at the suspension end of the suspension arm 22.

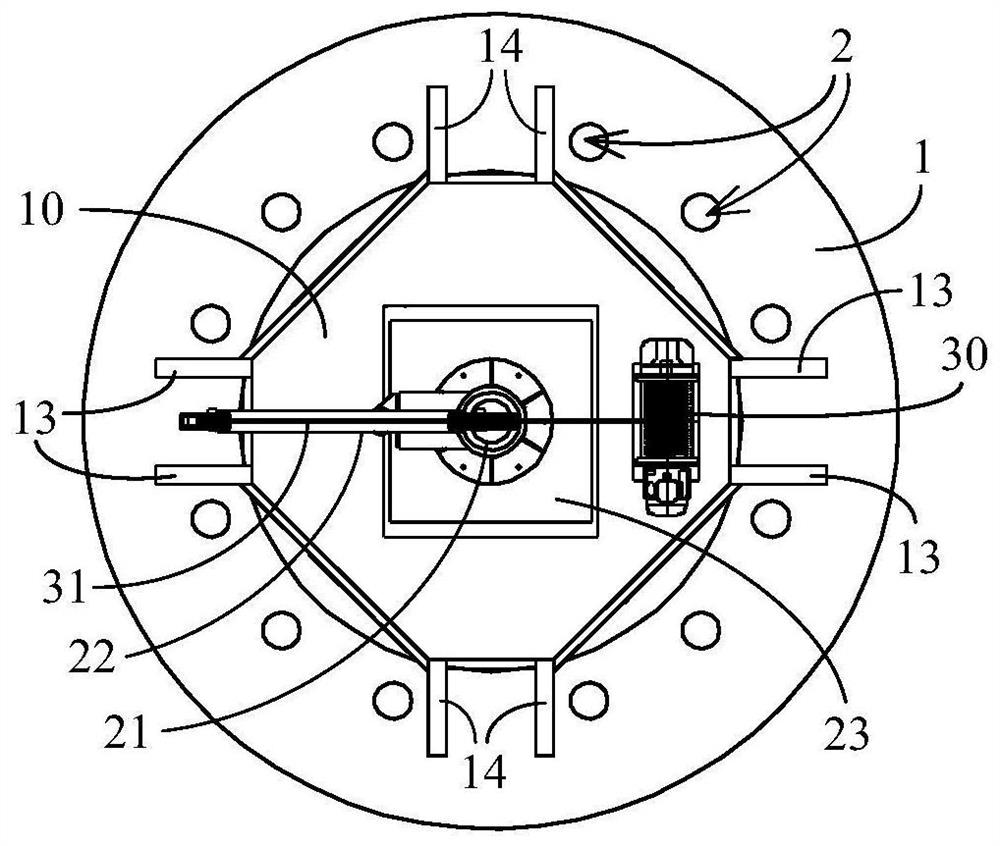

[0019] as attached Figure 1-3 As shown, the cable hole 2 is usually arranged around the core of the concrete tower body 1 . When in use, the base 10 is installed on the top of the concrete tower body 1, so that the axis of the column 21 coincides with the axis of the tower body 1, and the extension length of the boom 22 is the same as that reserved on the tower body 1. The cable hole 2 is consistent with the distance from the shaft center of the tower body 1, so that the tractio...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that the base 10 is composed of several base bodies that are detachably connected, which is convenient for the transportation of the crane. Hoist 30, support 23 and reversing wheel 32 are fixedly installed on the same base. Specific as attached Figure 4-6 As shown, the base 10 includes a strip-shaped middle seat 11 as a whole, side seats 12 are symmetrically arranged on both sides of the middle seat 11, and a winch 30, a bracket 23 and a reversing wheel 32 are fixedly installed on the middle seat. 11 above, shipped as attached Figure 5 As shown, the middle seat body 11 and the two side seat bodies 12 are separated, and if the transportation height is limited, the column 21 and the bracket 23 can be further separated. This example is attached Figure 6 As shown, two trapezoidal side seats 12 are symmetrically arranged on both sides of the middle seat 11, and the base 10 is generally in the shape of a regular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com