Separation traction device

A traction device and adjustment device technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of inconspicuous indentation, damage to paper, machine failure, etc., to improve operation stability, improve versatility, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

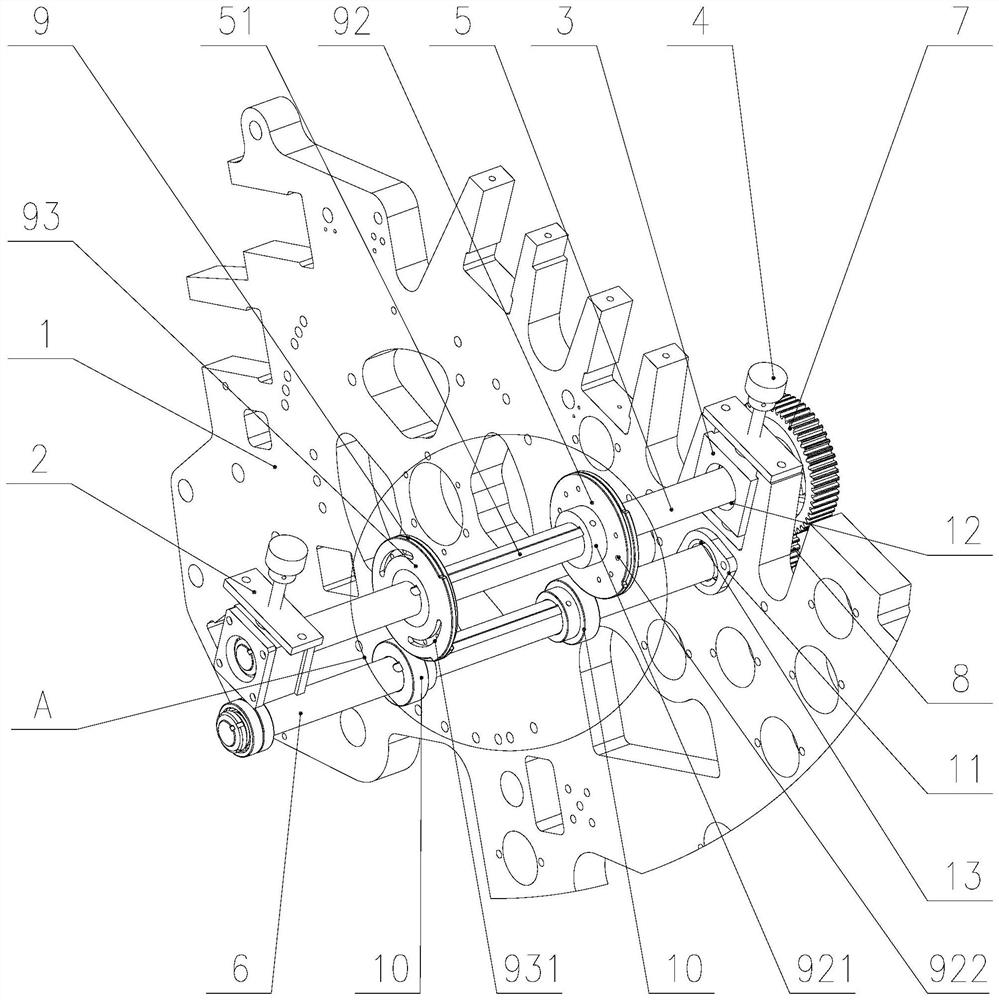

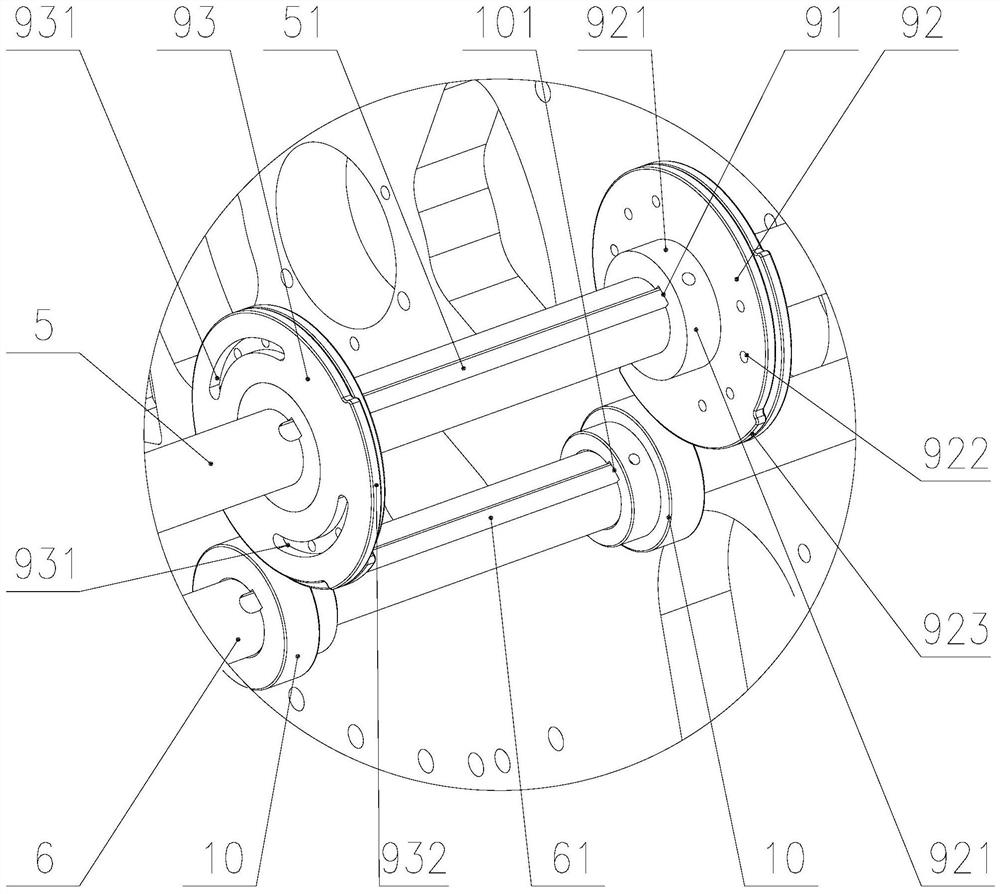

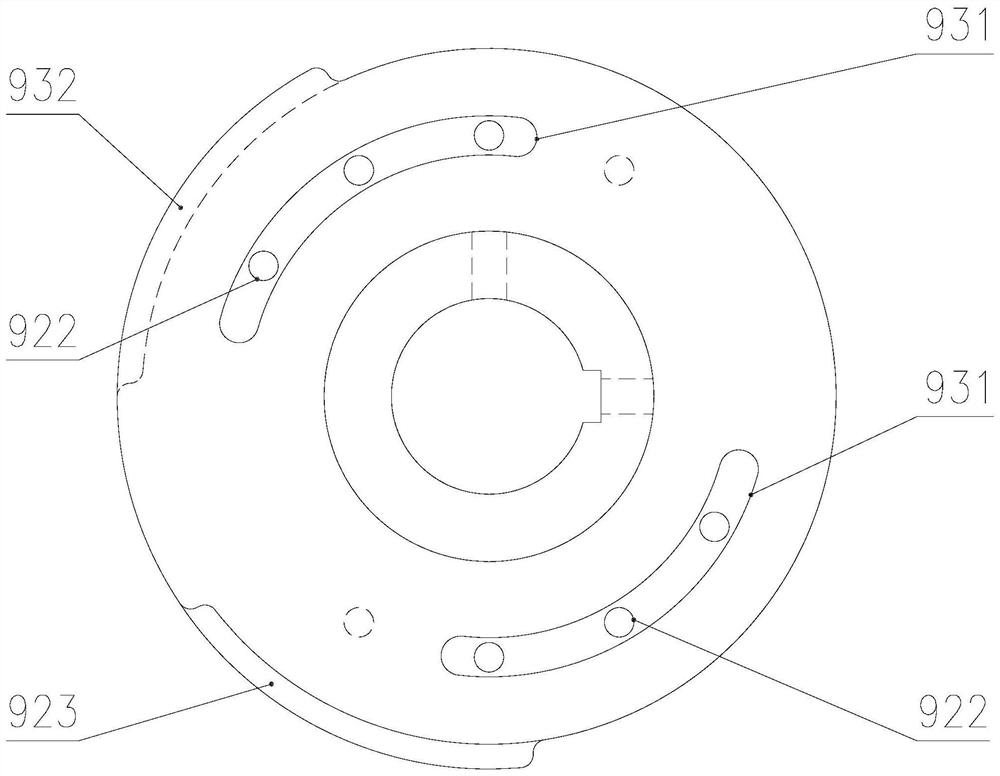

[0023] like figure 1 The shown tensioning and pulling device includes a wall plate 1, two fixed plates 2 symmetrically connected to the wall plates 1 on both sides, two sliding blocks 3, two sliding block adjusting devices 4, and pulling material. The pressing roller shaft 5, the pulling material pulling lower shaft 6 arranged in parallel under the pulling material pulling pressing roller shaft 5, the pulling material pulling gear 7 and the pulling lower gear 8 arranged on the outer side of the wall panel 1, two groups of pulling pressure Wheel assembly 9 and two pulling pulleys 10 for pulling material.

[0024] The sliders 3 are respectively arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com