Disposable slipper production machine

A production machine, one-off technology, applied in the direction of shoe-making machinery, footwear, soles, etc., can solve the problems of complex structure of the transmission device, low working reliability, inability to cut, continuous cutting, etc., to achieve work stability and Improve reliability, reduce installation footprint, and solve the effect of continuous cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0066] (Example 1)

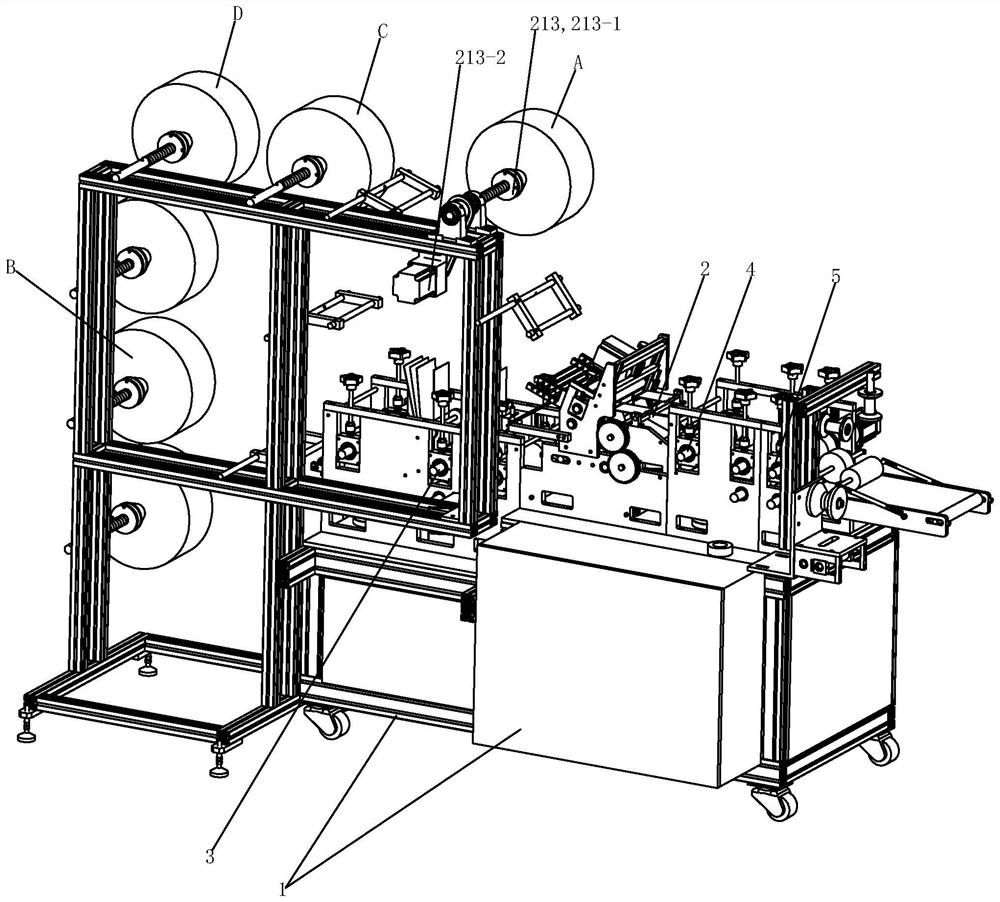

[0067] In this embodiment, when describing the orientation, the figure 1 The direction facing is the front in the description, to the back figure 1 The direction is the rear in the description, figure 1 The up and down and left and right directions in the description are still the up and down and left and right directions in the description. figure 1 The left side of the middle is the shipping direction of the finished disposable slippers during the manufacturing process.

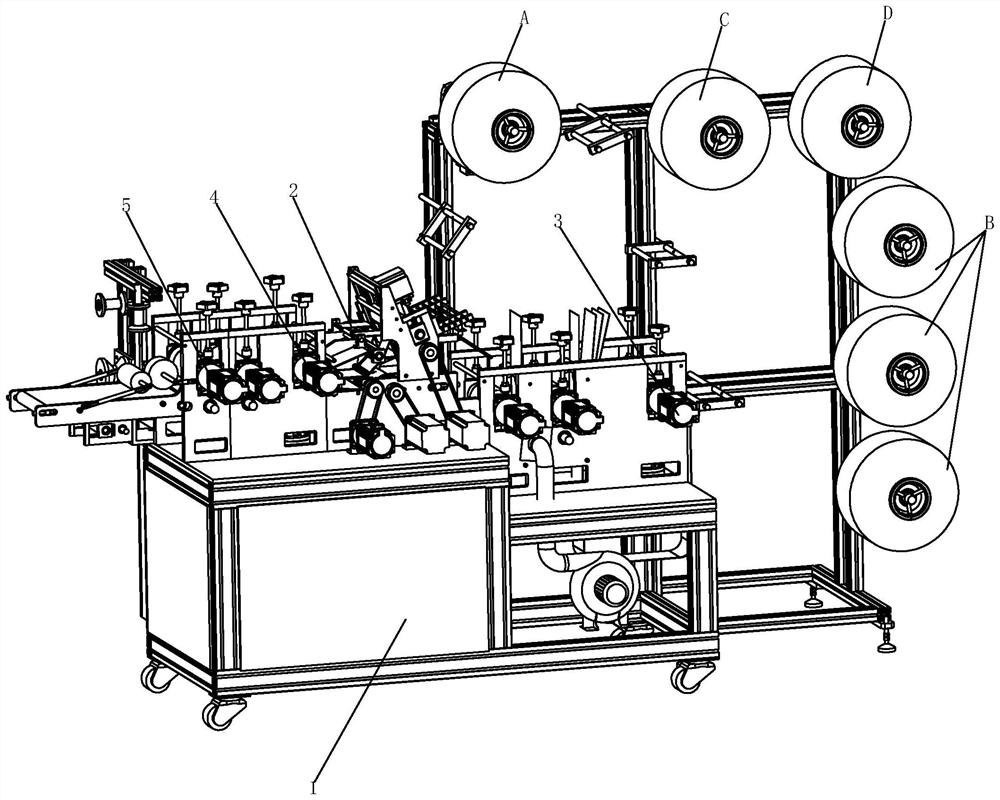

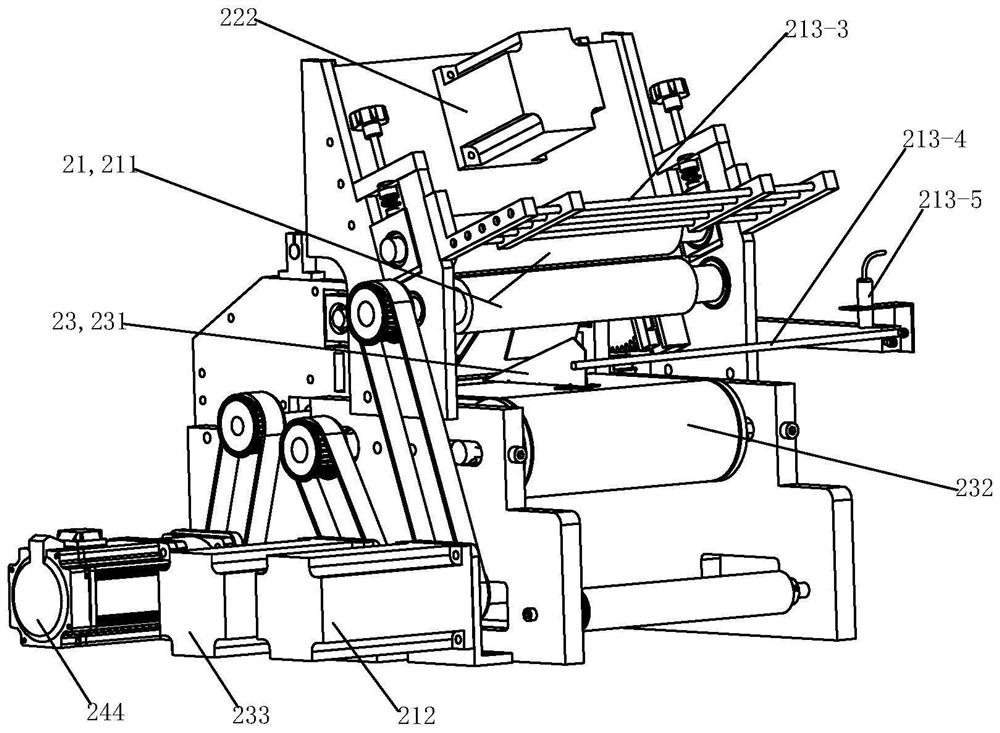

[0068] See figure 1 and figure 2 , the disposable slippers production machine of the present embodiment is mainly composed of a rack 1 as an installation base, a shoe upper raw material A for processing into a formed shoe upper blank E (such as Figure 11 The upper blank processing device 2 is used to process the sole raw material (including the sole bottom material B, the sole filler C, and the sole material D) into the sole blank F (such as Figure 11 shown) sole blank processing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap