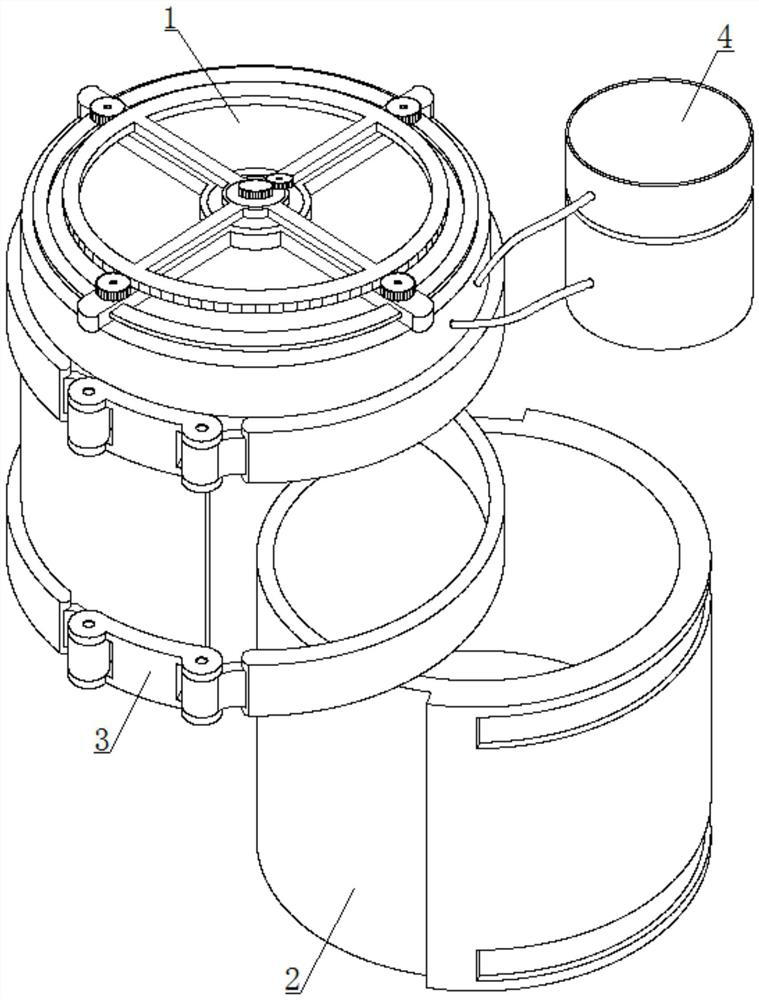

Plant extraction device and plant extraction method thereof

A plant extraction and surface installation technology, applied in separation methods, chemical instruments and methods, grain processing, etc., can solve the problems of waste of resources, waste of raw materials, and high cleaning power, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0053] In order to further explain the above examples better, the present invention also provides an embodiment, a plant extraction method of a plant extraction device, comprising the following steps:

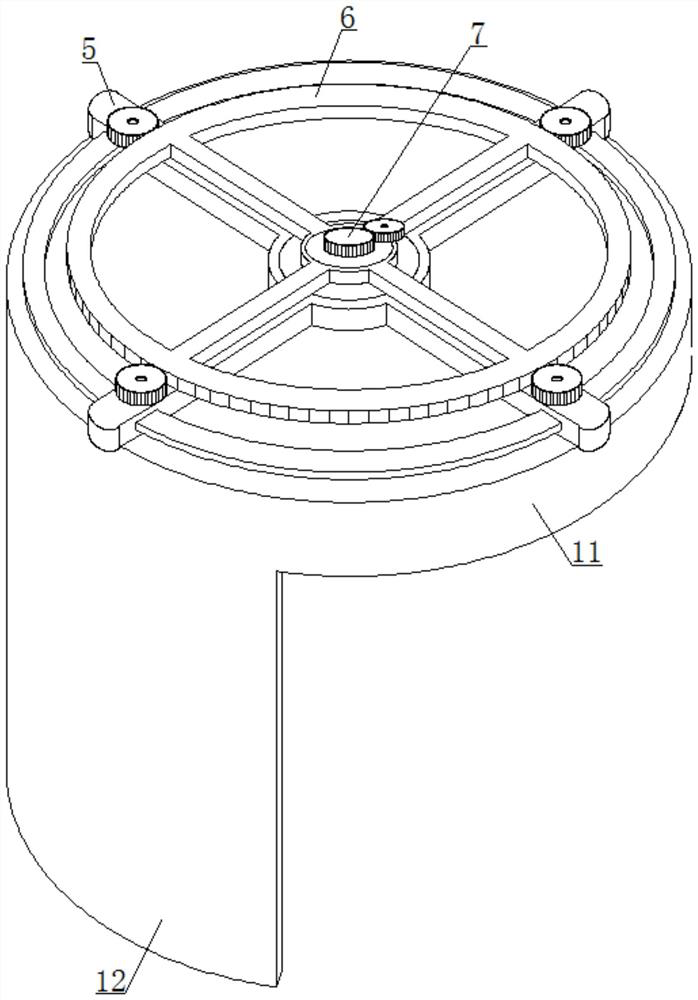

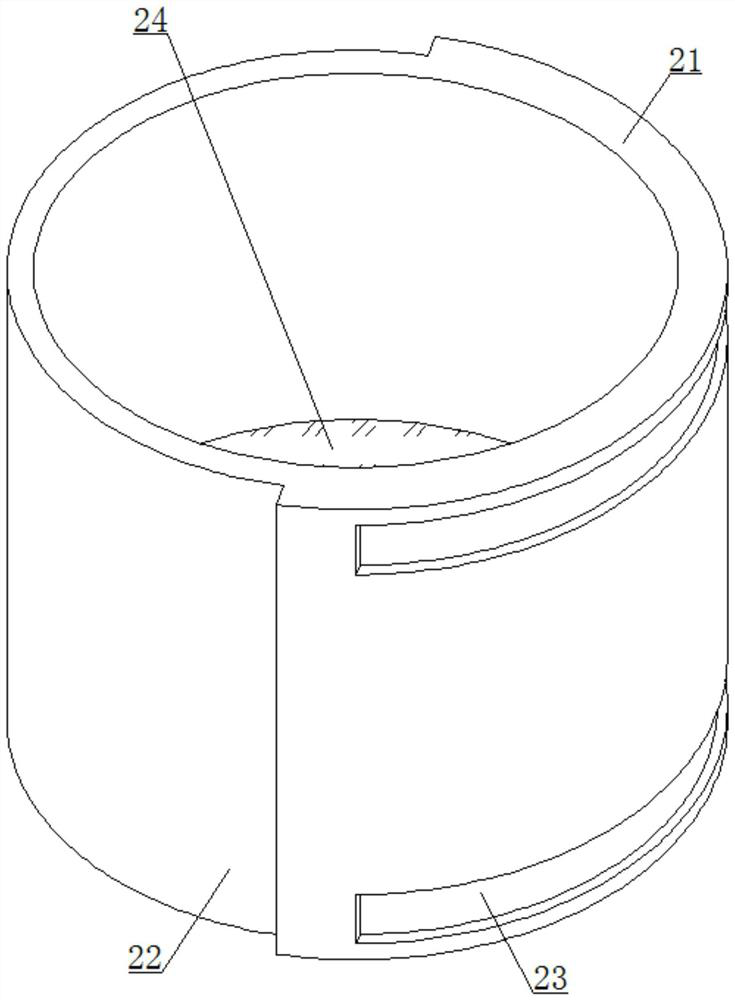

[0054] Step 1: Place the plant material to be extracted inside the second casing 21, and snap the second casing 21 to the bottom of the first casing 11 from bottom to top along the lower end of the first casing 11. On the inner side, rotate the arc-shaped swing rods 32 on both sides, and the locking rod 37 drives the matching column block 372 to engage with the inner side of the U-shaped block 3651;

[0055] Step 2: Rotate the rotating handle block 3644 to make the outer rotating ring 3641 rotate at a certain angle along the fixed ring 3648, and the connecting block 3643 rotates at the same angle along the arc-shaped movable groove 3649 to drive the arc-shaped locking plate 3646 to make the arc-shaped The long lock slot 3647 is locked with the lock rod body 371;

[0056] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com