Integrated reaction precipitation separation tank

A precipitation separation and precipitation tank technology, applied in the field of precipitation tanks, can solve the problems affecting the normal use of precipitation and separation tanks, large volume of stirring and cleaning components, lack of cleaning effect, etc., and achieves good applicability, small size, and improved secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

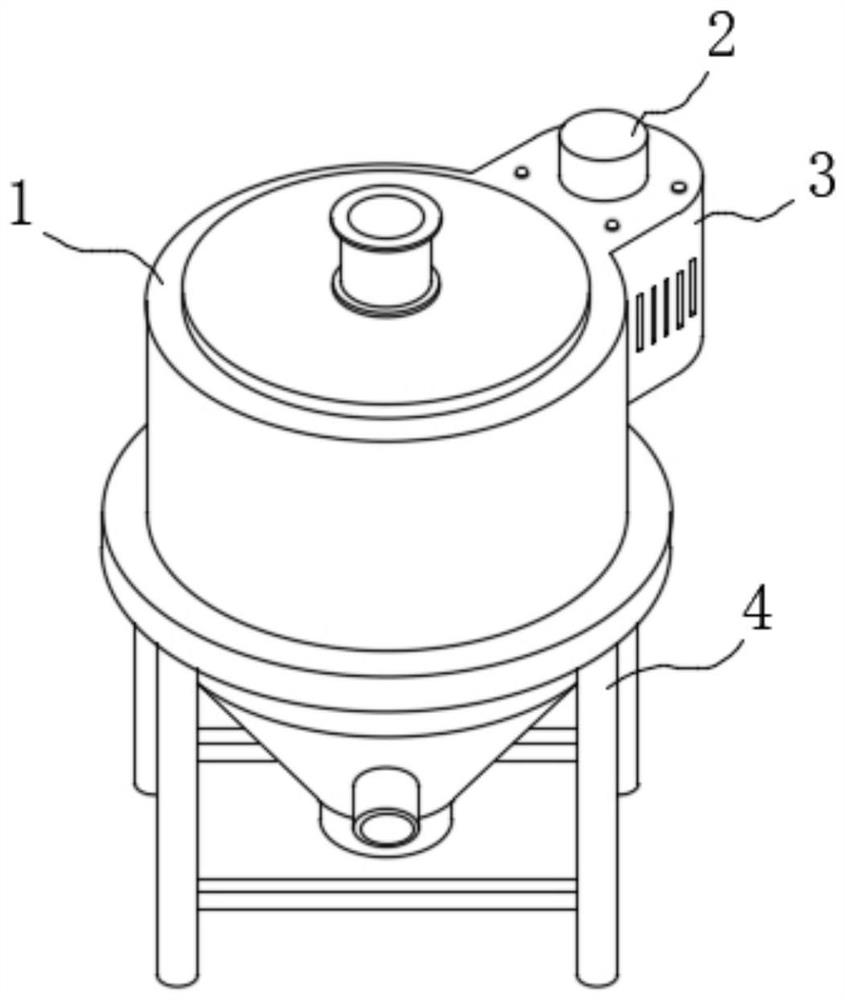

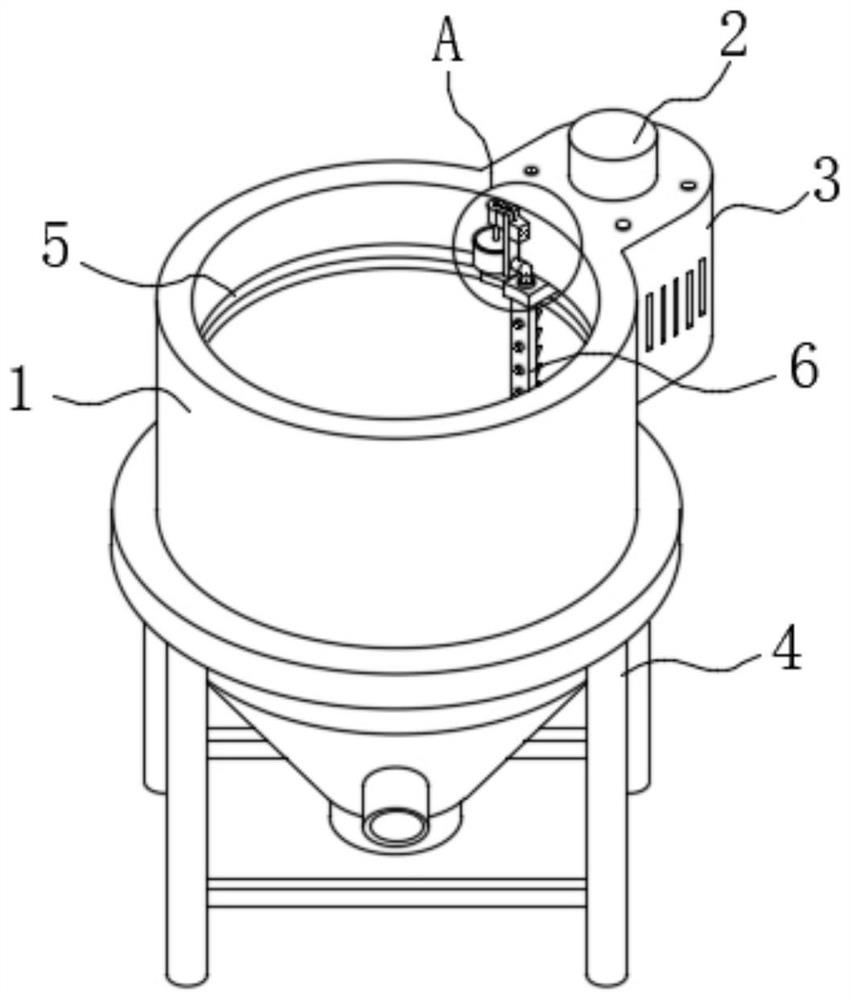

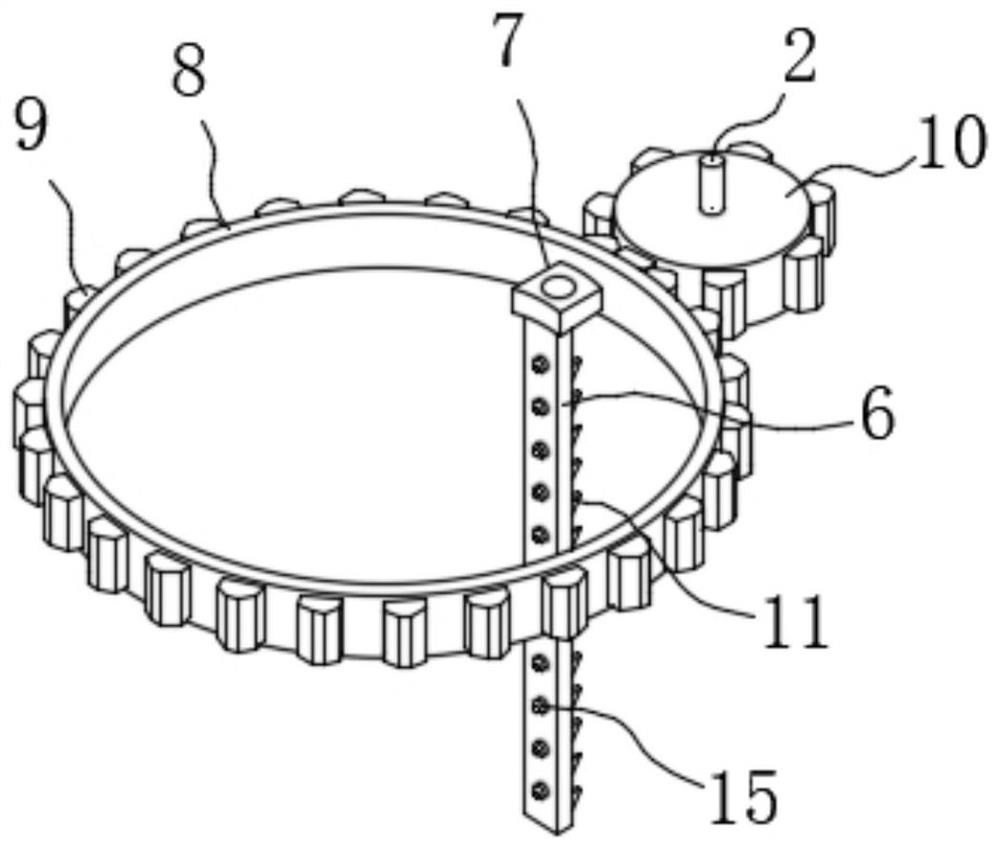

[0024] like Figure 1-Figure 6 The shown integrated reaction sedimentation separation tank includes a sedimentation tank body 1, a chassis 3 is arranged on the back of the sedimentation tank body 1, an inner notch 5 is opened on the inner wall of the sedimentation tank body 1, and a servo motor 2 is installed on the upper surface of the chassis 3. , the output shaft of the servo motor 2 is fixedly connected with a gear 10, a transmission ring body 8 is arranged in the inner slot 5, the outer wall of the transmission ring body 8 is meshed with the gear 10 through the teeth 9, and the inner wall of the transmission ring body 8 is fixedly connected with a A vertical plate 6 is fixedly connected to the lower surface of the installation block 7 , a plurality of scrapers 11 are arranged on the back of the vertical plate 6 , and a plurality of baffles 13 are fixedly connected to the back of the vertical plate 6 .

[0025] During use, when it is necessary to clean the sedimentation se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com