Double-faced adhesive tape tearing station for adhesive tape pasting and film tearing production

A double-sided tape and adhesive technology, which is used in thin material handling, mechanical conveyors, sending objects, etc., can solve the problems of inability to cover double-sided tape, small visual field of vision, and inability to locate products, and achieve good protection effects. Easy operation and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

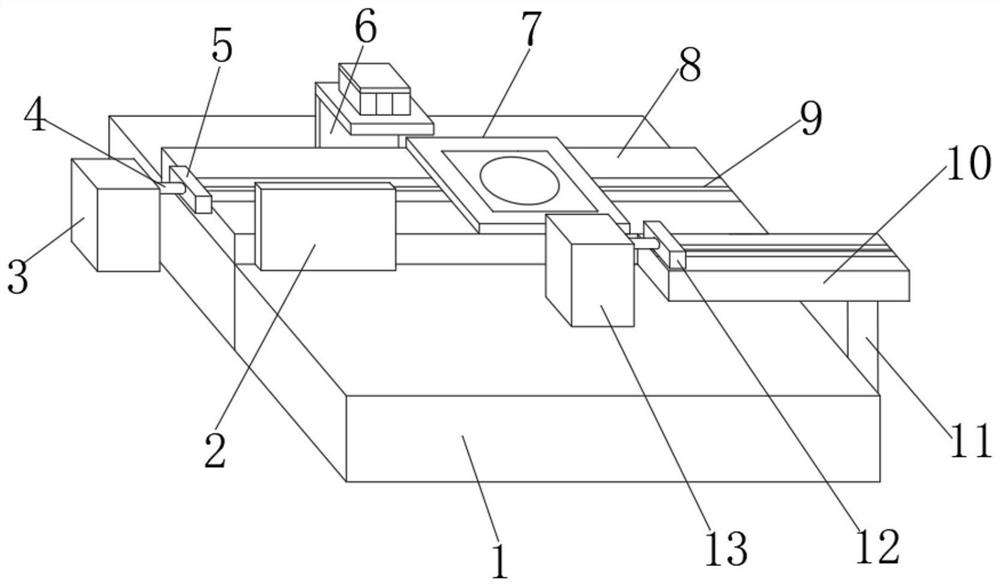

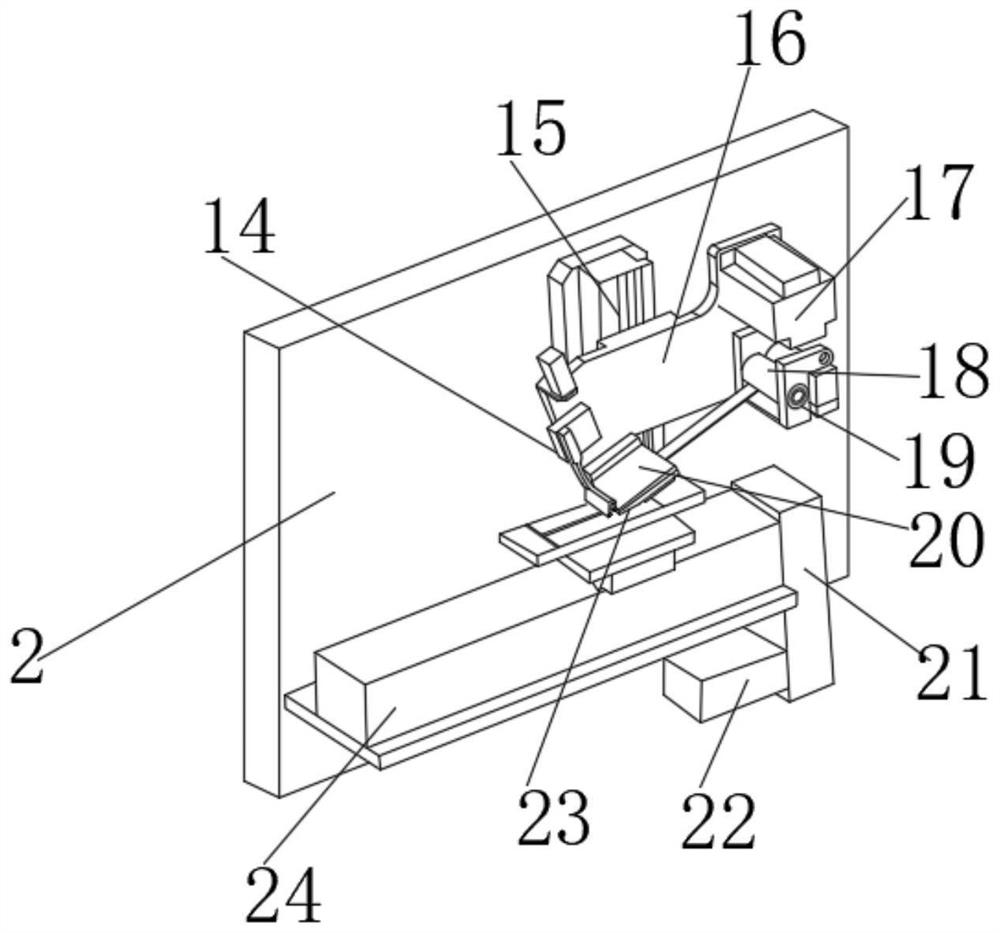

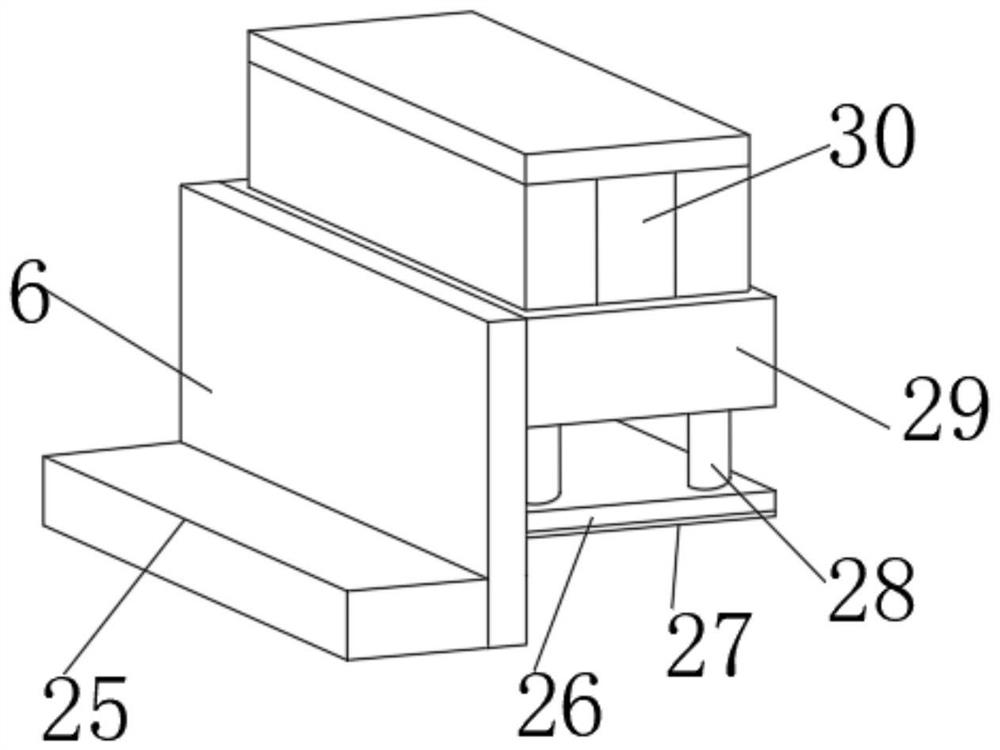

[0028] like Figure 1-6 As shown in the figure, a double-sided adhesive tape tearing film production station for sticking and tearing film includes a sticking seat 1, the upper end of the sticking seat 1 is positioned and installed with a carrier assembly line 8, and a pressure product is installed on the rear side of the carrier assembly line 8 Module 6, the front side of the carrier assembly line 8 is equipped with a tear-off film module 2 and a product blanking module 10, a slide rail 9 is provided in the middle of the carrier assembly line 8, and a carrier 7 is provided on the upper end of the carrier assembly line 8, which is glued A carrier driving cylinder 3 is installed on one end of the base 1, a driving rod 4 is connected to the carrier driving cylinder 3, a driving block 5 is connected to the end of the driving rod 4, and a positioning frame 11 is installed at the bottom of the product unloading module 10, One end of the product blanking module 10 is provided with a...

Embodiment 2

[0033] On the basis of Example 1, as Figure 1-6 As shown in the figure, a double-sided adhesive tape tearing film production station for sticking and tearing film includes a sticking seat 1, the upper end of the sticking seat 1 is positioned and installed with a carrier assembly line 8, and a pressure product is installed on the rear side of the carrier assembly line 8 Module 6, the front side of the carrier assembly line 8 is equipped with a tear-off film module 2 and a product blanking module 10, a slide rail 9 is provided in the middle of the carrier assembly line 8, and a carrier 7 is provided on the upper end of the carrier assembly line 8, which is glued A carrier driving cylinder 3 is installed on one end of the base 1, a driving rod 4 is connected to the carrier driving cylinder 3, a driving block 5 is connected to the end of the driving rod 4, and a positioning frame 11 is installed at the bottom of the product unloading module 10, One end of the product blanking modul...

Embodiment 3

[0037] On the basis of Embodiment 1 and Embodiment 2, as Figure 1-6 As shown in the figure, a double-sided adhesive tape tearing film production station for sticking and tearing film includes a sticking seat 1, the upper end of the sticking seat 1 is positioned and installed with a carrier assembly line 8, and a pressure product is installed on the rear side of the carrier assembly line 8 Module 6, the front side of the carrier assembly line 8 is equipped with a tear-off film module 2 and a product blanking module 10, a slide rail 9 is provided in the middle of the carrier assembly line 8, and a carrier 7 is provided on the upper end of the carrier assembly line 8, which is glued A carrier driving cylinder 3 is installed on one end of the base 1, a driving rod 4 is connected to the carrier driving cylinder 3, a driving block 5 is connected to the end of the driving rod 4, and a positioning frame 11 is installed at the bottom of the product unloading module 10, One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com