Surface pretreatment process for steel wire processing

A surface pretreatment and pretreatment technology, which is applied to the improvement of process efficiency, cleaning methods and tools, cleaning methods using tools, etc., can solve problems such as unsafe use, complicated lead wire operation, acid damage to operators, etc., to achieve Easy lead wire, good cleaning effect and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

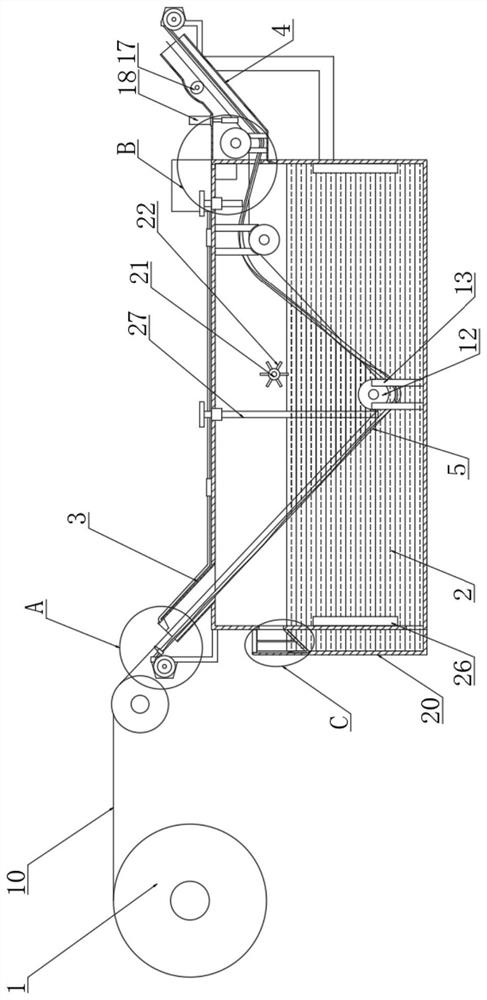

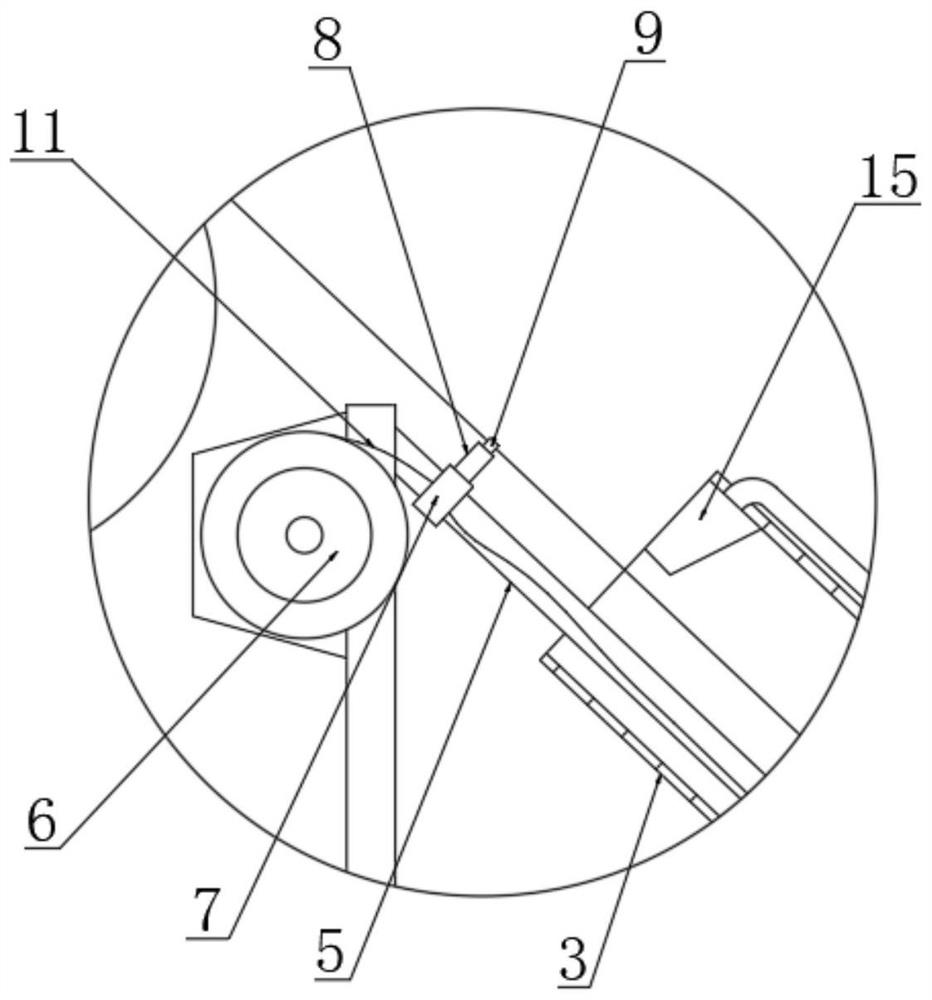

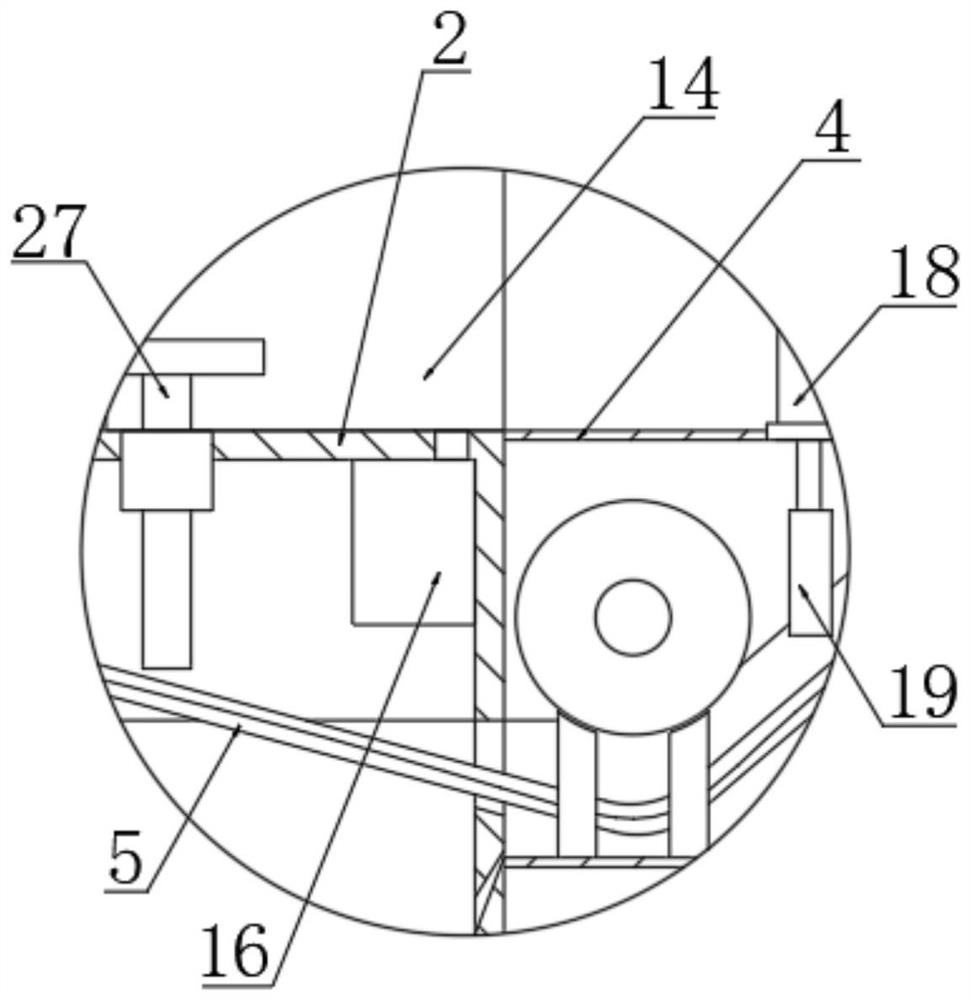

[0031]In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0032] see Figure 1-4 , the present invention provides a technical scheme: a surface pretreatment process for steel wire processing comprises the following steps:

[0033] Step 1. The steel wire 10 is conveyed by the feeding roller 1 of the pretreatment equipment, and then the lead wire is passed through the traction mechanism of the pretreatment equipment, then the steel wire 10 is pulled, and then the sliding member 7 is reset, so that the steel wire 10 can be quickly passed through. Treatment box 2, no need to open the box for operation, can effectively prevent the internal acid mist from leaking and affect safety, and through anti-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com