Visual positioning plate searching device and method for sorting large-size workpieces

A visual positioning, large-scale technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of low efficiency, complicated logic, and large amount of calculation when replacing the end pickup, achieve a wide range of practical value, reduce the number of shots, calculate small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

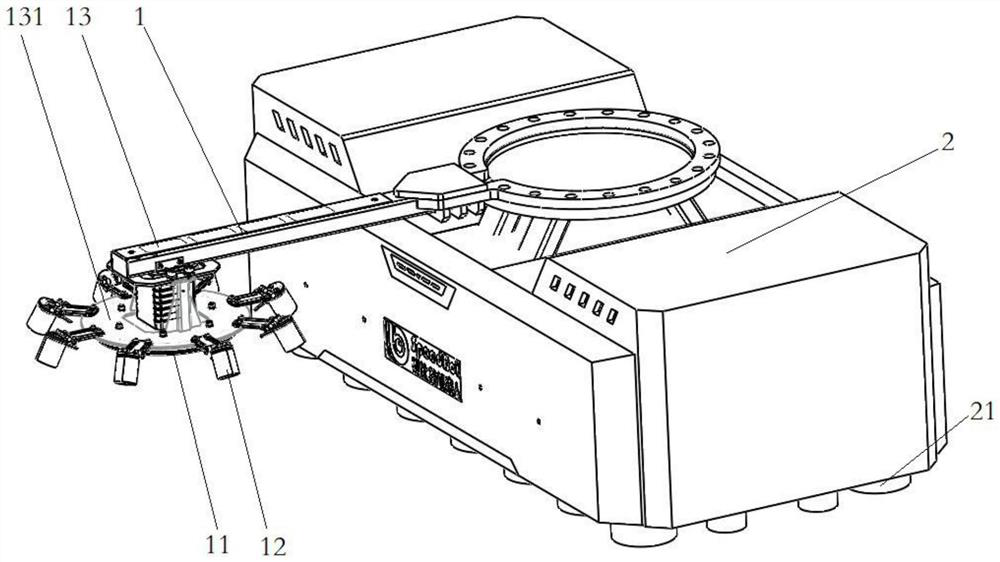

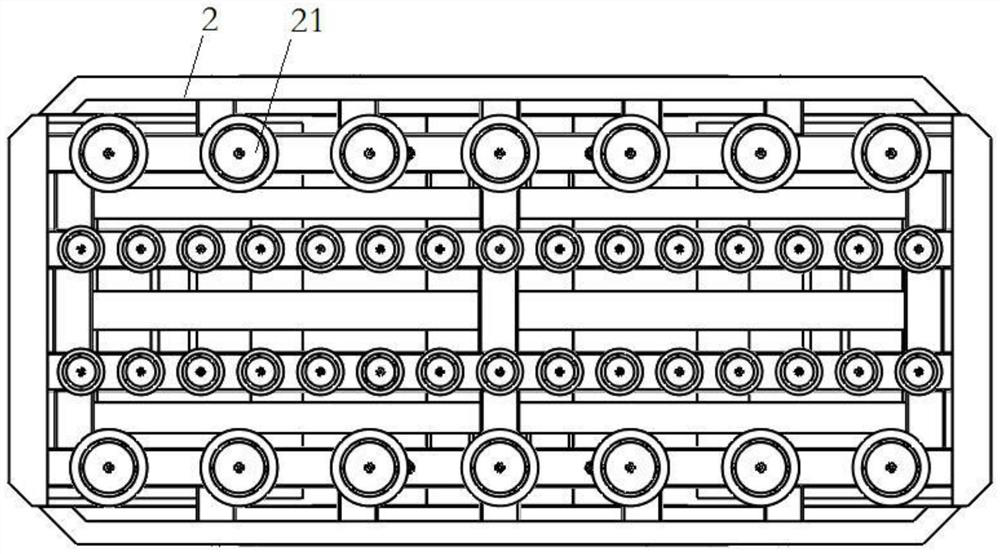

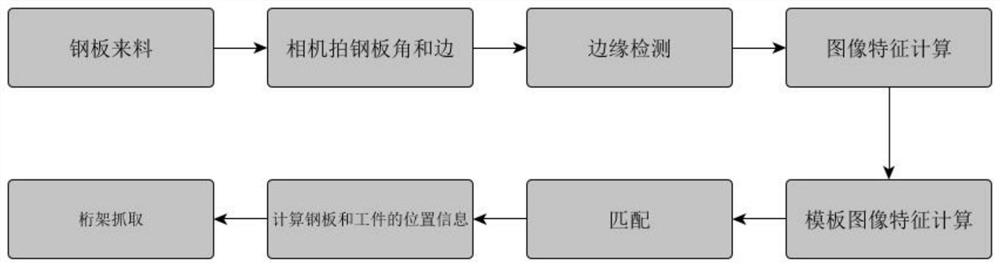

[0033] as Figure 1 As shown, the visual positioning plate finding device for large-size workpiece sorting of the present embodiment, comprising a camera device 1, a terminal picker 2 and a control system, the camera device 1 and the end picker 2 are communicated with the control system; the camera device 1 is used to obtain at least one image containing the corner point of the steel plate and at least one image containing the edge of the steel plate part, and is sent to the control system; the control system is used to obtain the position information of the steel plate and the corresponding position information of each workpiece according to the received image and the preset steel plate nesting chart, According to the position information of each workpiece, the driver picker 2 picks up the workpiece. This embodiment of this setup mode can realize the automatic picking of the workpiece only through a simple structure, and because of the combination of the blanking diagram of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com