System for automatically collecting tyre surfaces with pressing lines

A technology for extrusion line tread and tread, which is applied in the field of tire manufacturing and can solve the problems of many operators and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

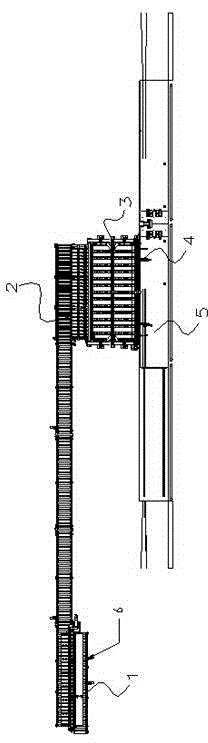

[0023] Such as figure 1 As can be seen from the schematic diagram, the automatic tread collection system of the present invention includes a tread conveying roller 6, a tread turning mechanism 1, a tread spacing adjustment and storage mechanism 2, a tread placing mechanism 3, a shutter turning mechanism 4, and a shutter Car automatic switching mechanism 5.

[0024] The tread turning mechanism 1 is set at the discharge port of the film conveying roller 6, the tread spacing adjustment and storage mechanism 2 is set at the side of the discharge port of the film conveying roller 6, and the tread placing mechanism 3 is set at the tread spacing adjustment And beside the discharge port of the storage mechanism 2, the louver turning mechanism 4 is arranged at the upper end of the tread injection mechanism 3, and the louver automatic switching mechanism 5 is arranged beside the tread injection mechanism 3.

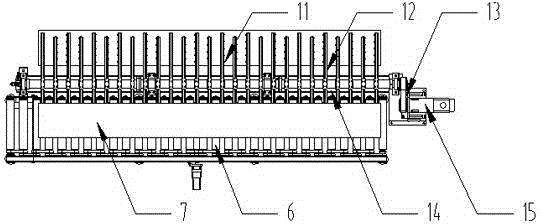

[0025] Such as figure 2 As shown in the schematic diagram, it can be seen that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com