Device for picking up breathable material in wafer box

A gas-permeable material and wafer box technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low efficiency and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

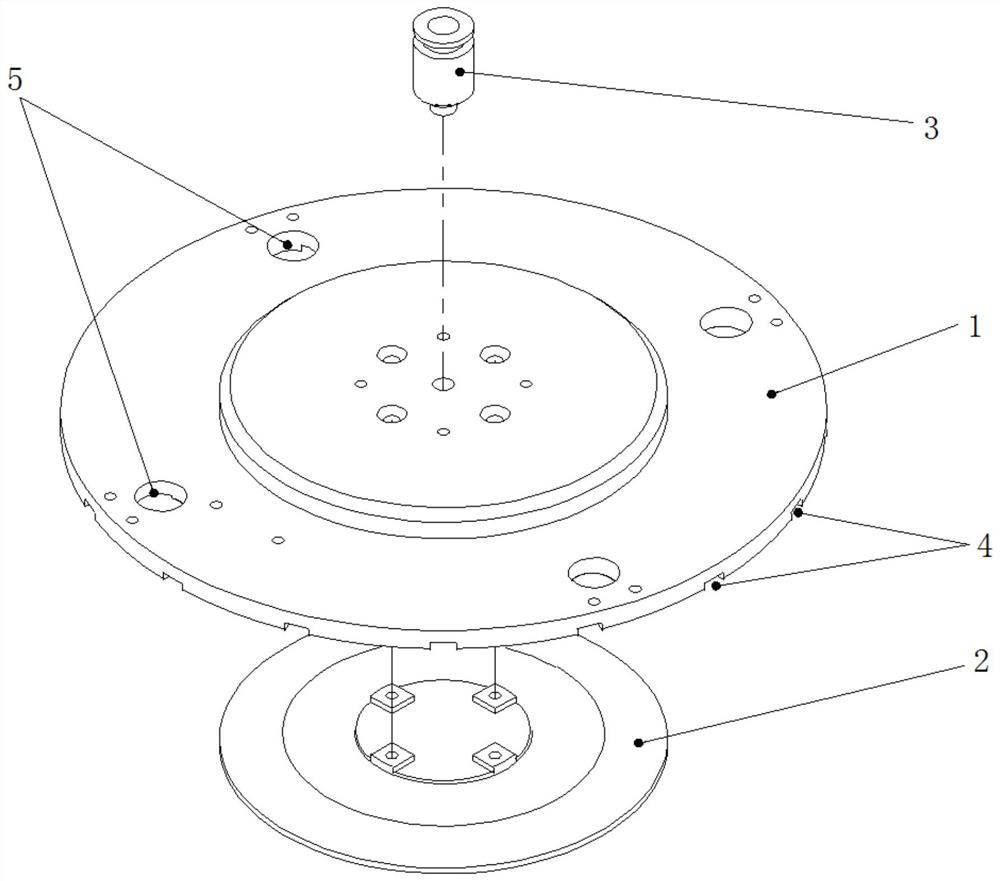

[0025] Such as figure 1 As shown, a device for picking up gas-permeable materials in a wafer cassette includes a Bernoulli disk 1, a deflector disk 2 and a gas pipe joint 3, and the deflector disk 2 is fixed on the middle area of the lower surface of the Bernoulli disk 1 and is connected with the An air circulation gap is formed between the Bernoulli disks 1, and the air circulation gap is connected to the air source through the air pipe joint 3, and the deflector plate 2 is used to conduct the airflow input into the air circulation gap to the side of the Bernoulli disk 1 dispersion.

[0026] Design Bernoulli disk 1 and guide disk 2, by passing air to the lower surface of Bernoulli disk 1, based on Bernoulli's principle, due to the large air velocity between Bernoulli disk 1 and the breathable material to be picked up, the pressure Reduced, the atmospheric pressure below the breathable material to be picked up pushes the breathable material to the Bernoulli disk 1, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com