Automatic unstacking and carrying device and method for angle steel

A handling device and angle steel technology, which is applied in the direction of object destacking, object stacking, transportation and packaging, etc., can solve the problems of heavy weight, difficult handling, and difficult hoisting of angle steel, and achieve the effect of convenient grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In a first aspect, the embodiments of the present application disclose an automatic destacking and handling device for angle steel.

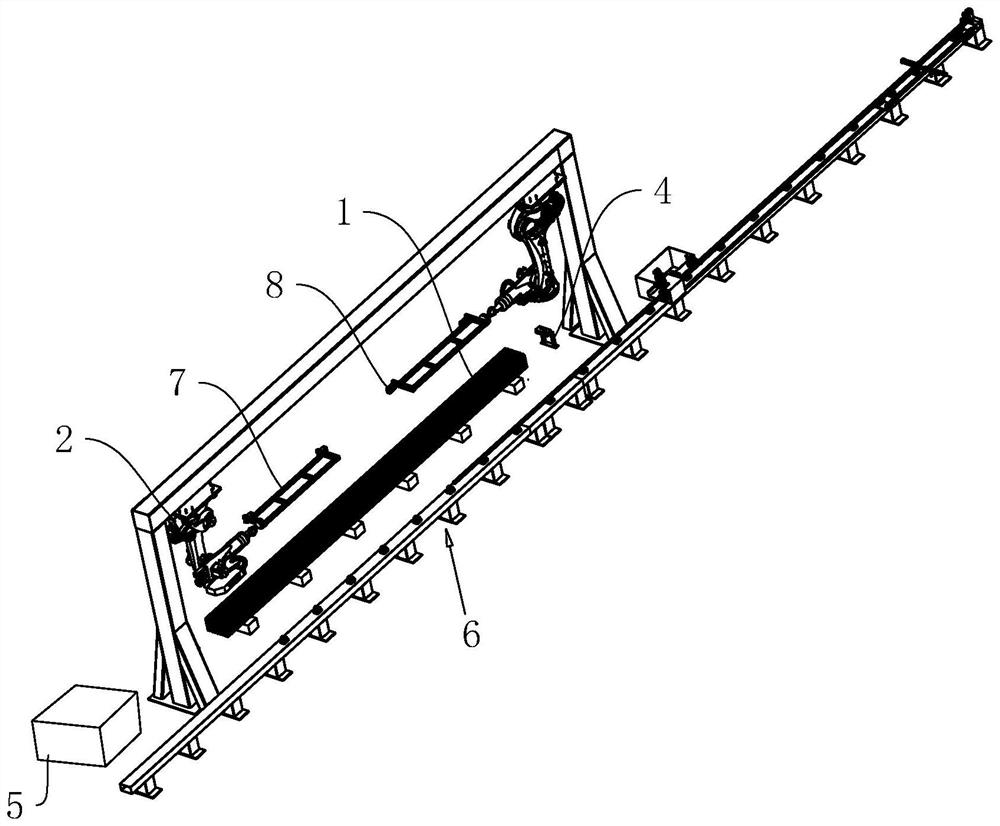

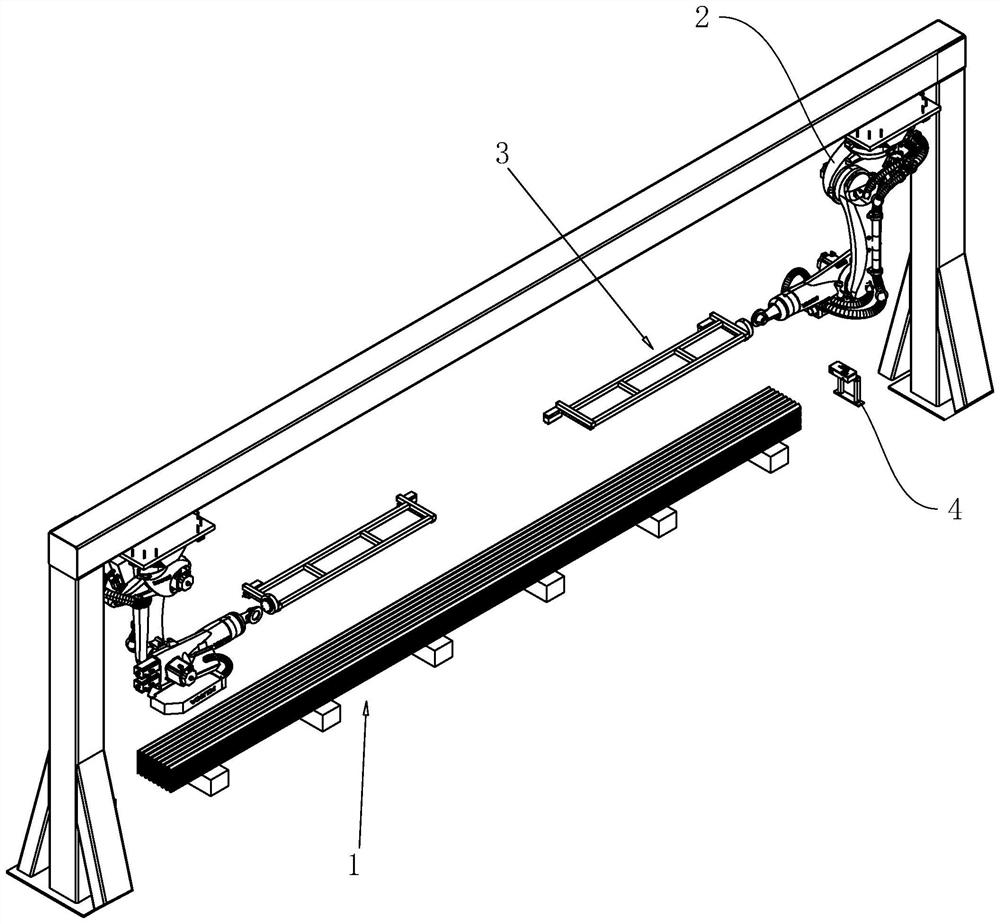

[0050] refer to figure 1 and figure 2 , an automatic destacking and handling device for angle steel, including a feeding platform 1, the feeding platform 1 is fixed on the ground, and the feeding platform 1 is a steel plate horizontally supported on the ground. The angle steel stacking type is a layer of positive V and a layer of inverted V staggered stacking.

[0051] refer to figure 1 and figure 2 , and also includes an image sensor 4, the image sensor 4 is an industrial camera, there are two image sensors 4, the two image sensors 4 are respectively arranged at both ends of the feeding platform 1, and the two image sensors 4 are fixed on the ground by steel brackets Above, the image sensor 4 is mainly used to take pictures of the end faces of the stacked angle steels.

[0052] refer to figure 1 and figure 2 , in order to facilit...

Embodiment 2

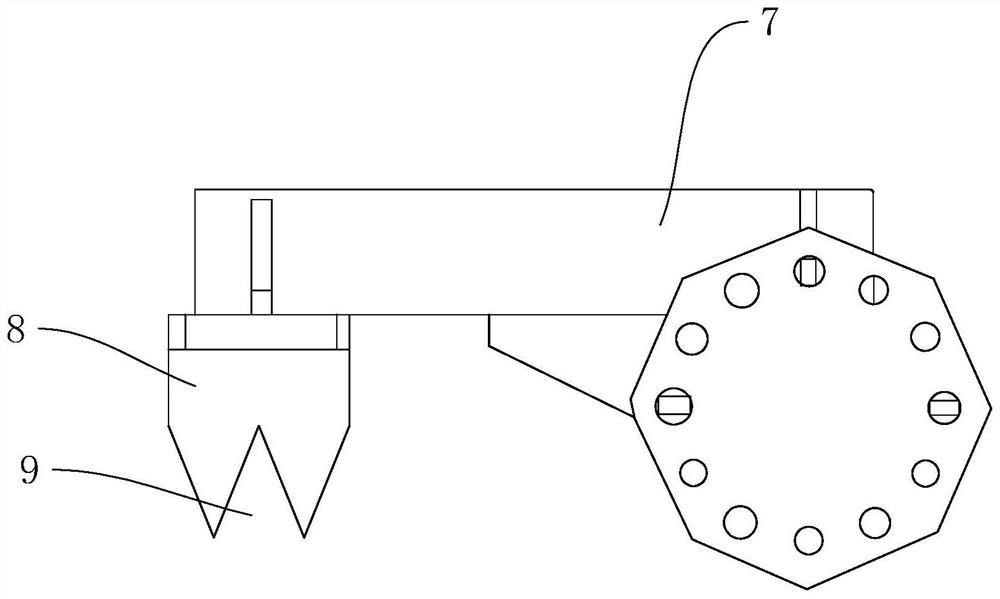

[0057] refer to Figure 4 and Figure 5 The difference between the second embodiment and the first embodiment is that the installation frame 7 is also provided with a magnetic lock piece 10 for preventing the angle steel from falling.

[0058] refer to Figure 5 , the magnetic lock 10 includes a mounting block 11, an electromagnetic tube 12, a lock lever 13 and a return spring 14. The mounting block 11 is fixed on the side wall of the electromagnetic block, and the electromagnetic tube 12 is fixed on the side wall of the mounting block 11. When the mounting frame When arranged in parallel, the axial direction of the electromagnetic tube 12 is parallel to the horizontal direction, and the mounting block 11 is provided with a mounting hole 15 which communicates with the inner cavity of the electromagnetic tube 12 . The lock rod 13 slides horizontally in the installation hole 15 , and the reset spring 14 is coaxially sleeved on the outside of the lock rod 13 .

[0059] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com