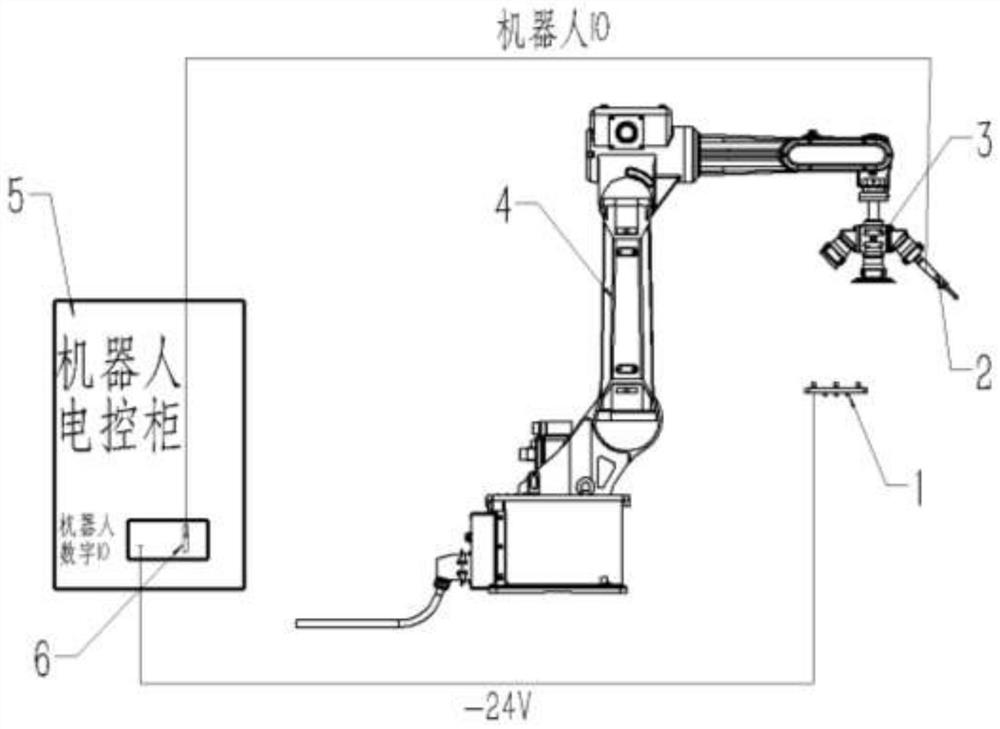

Industrial robot automatic tool workpiece calibration method

A technology of industrial robots and automatic tools, applied in the direction of manufacturing tools, manipulators, program-controlled manipulators, etc., can solve problems such as operational errors, low efficiency, and poor precision, and achieve the effect of improving contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The edge finder assembly can be replaced with higher cost ruby machine contacts:

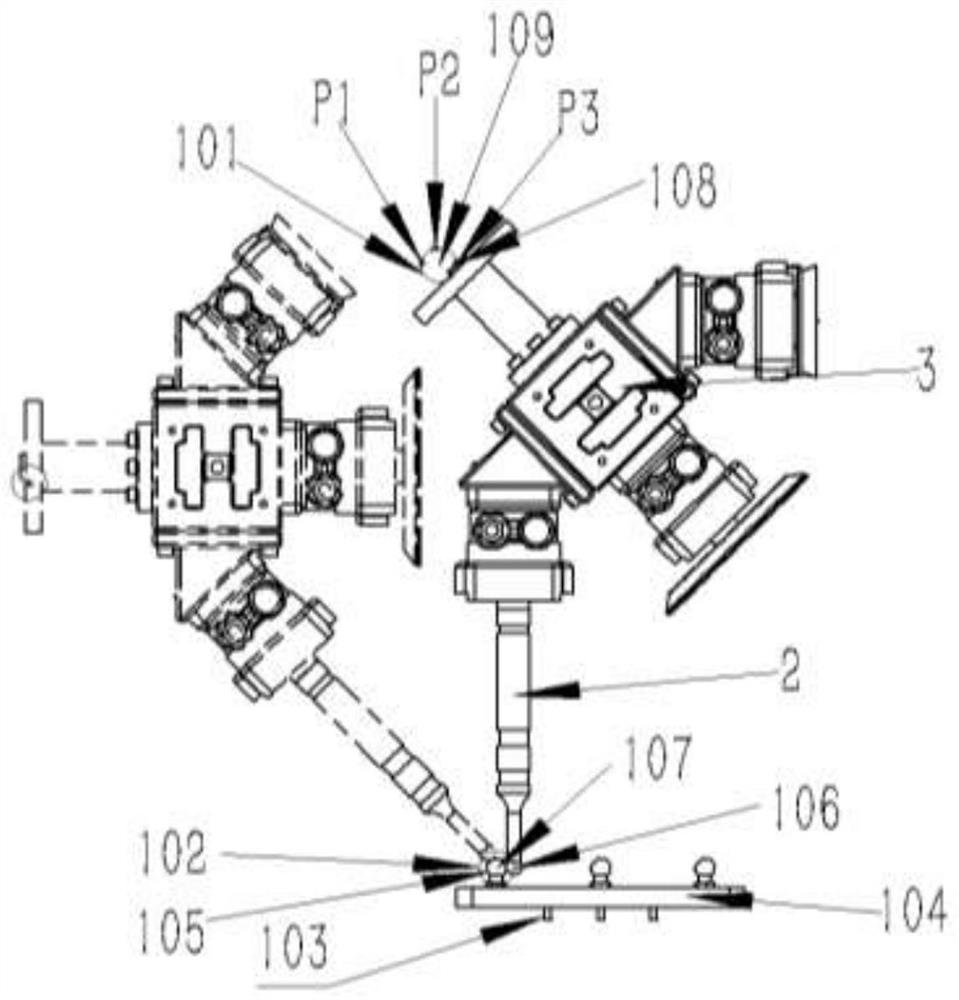

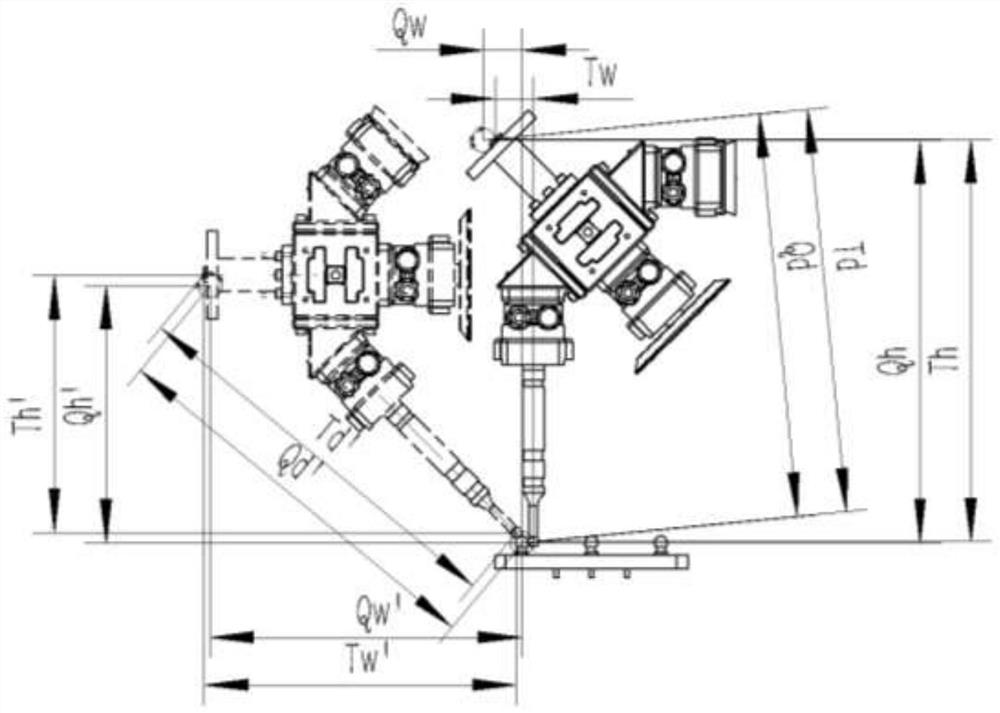

[0046] Step 1: Connect all hardware parts according to the structure and connection relationship. Step 2: Operate the 4-industrial robot to make the 2-edge finder point in front of the 105-reference ball. At this time, the 2-edge finder is not in contact with the 105-reference ball. Step 3: Run the robot automatic calibration program, the robot will automatically find the 105-reference ball with a fixed posture, so that the 2-edge finder is in contact with the 105-reference ball. Step 4: 4- The robot automatically runs in a fixed posture and contacts the 105-reference ball three times, and records the three points P1, P2, and P3 respectively. Step 5: According to the three points P1, P2 and P3, find the center of the circle and calculate the coordinates of the center of the 109-robot running track. Step 6: Change 4- Robot Pose. Step 7: Repeat step 2, repeat step 3, repeat step 4, rep...

Embodiment 2

[0048] The reference ball is a calibration reference standard for machine tool processing, which can be processed by yourself or used by purchasing standard parts from suppliers:

[0049] Step 1: Connect all hardware parts according to the structure and connection relationship. Step 2: Operate the 4-industrial robot to make the 2-edge finder point in front of the 105-reference ball. At this time, the 2-edge finder is not in contact with the 105-reference ball. Step 3: Run the robot automatic calibration program, the robot will automatically find the 105-reference ball with a fixed posture, so that the 2-edge finder is in contact with the 105-reference ball. Step 4: 4- The robot automatically runs in a fixed posture and contacts the 105-reference ball three times, and records the three points P1, P2, and P3 respectively. Step 5: According to the three points P1, P2 and P3, find the center of the circle and calculate the coordinates of the center of the 109-robot running track....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com