Squeezing type carton film laminating machine capable of avoiding bubbles

A laminating machine, extrusion-type technology, applied in the field of extrusion-type carton laminating machine, can solve the problems of insufficient lamination safety, separation of film and carton board, and weak bonding, etc., to ensure stability The effect of moving, avoiding bubbles or bulges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

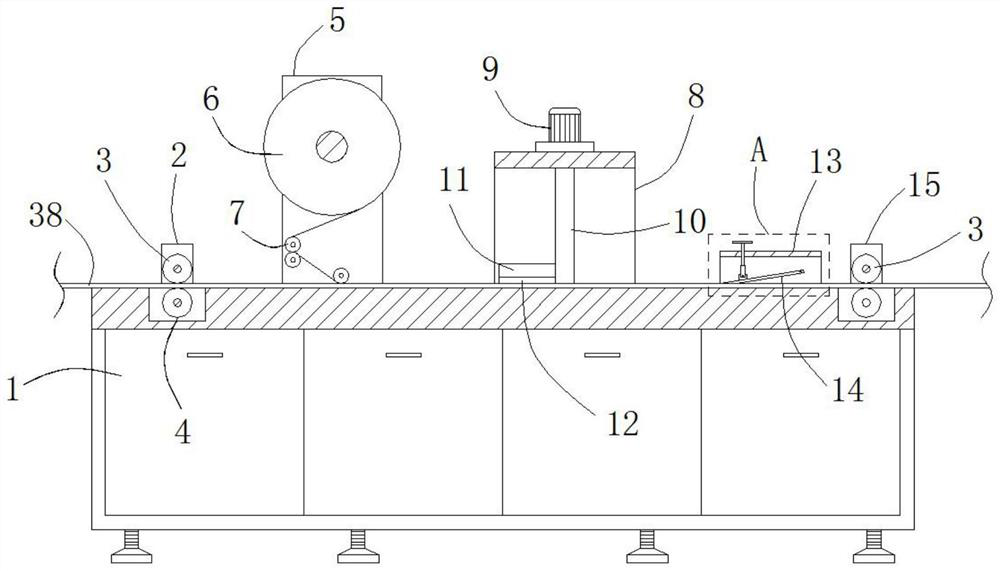

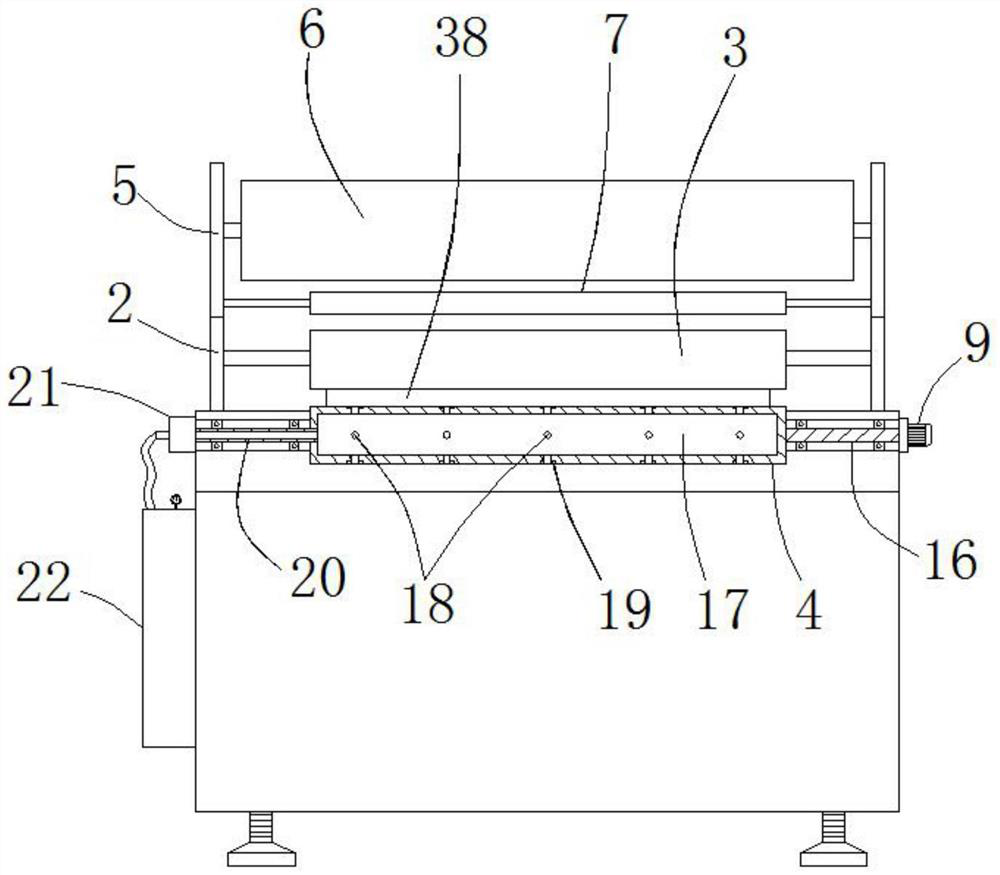

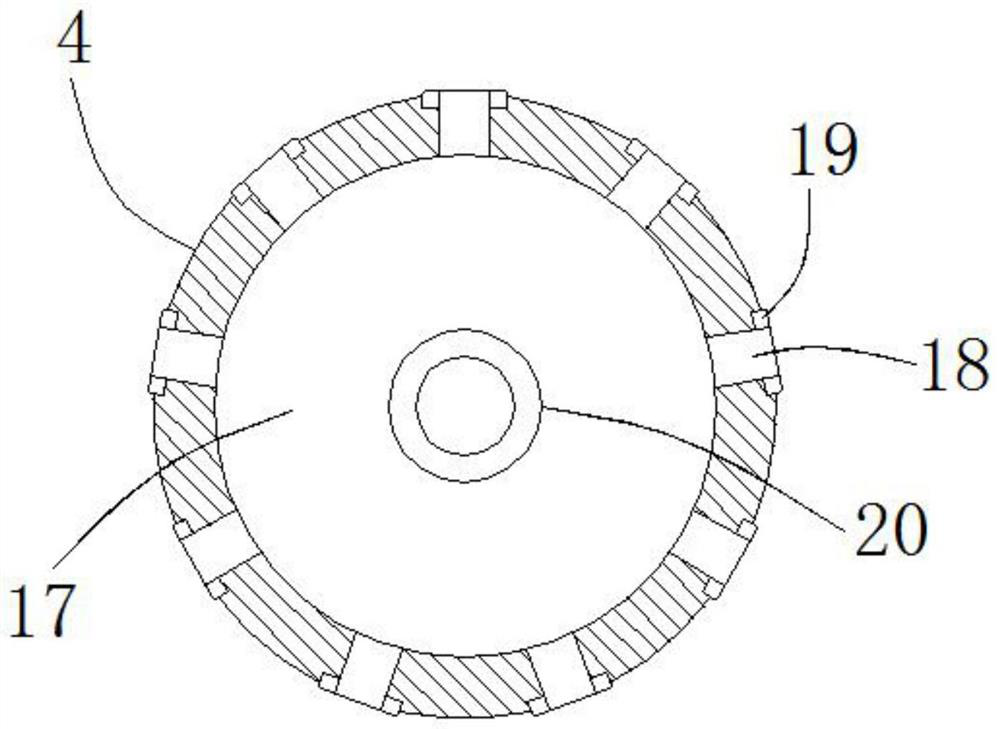

[0034]An extrusion-type carton laminating machine for avoiding air bubbles includes a laminating machine body 1, an input mechanism 2 is arranged on the upper part of one side of the laminating machine body 1, and a horizontally arranged driven roller 3 is arranged above the inner side of the input mechanism 2. , a rotatable driving roller 4 is embedded in the upper end surface of the laminator body 1 under the driven roller 3, a carton board 38 is passed between the driven roller 3 and the driving roller 4, and the rear side of the input mechanism 2 is provided with a The laminating mechanism 5 for laminating the carton board 38 is provided with a laminating roller 6 on the inner upper part of the laminating mechanism 5, and a tension roller 7 for unwinding the film is provided below the laminating roller 6. The side is provided with a scraping and defoaming mechanism 8 for pressing and spreading the film. The rear side of the scraping and defoaming mechanism 8 is provided wit...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that two motors 9 are provided on the upper part of the top of the scraping and defoaming mechanism 8 , and the output end of the motors 9 is connected to the turret 10 below the scraping and defoaming mechanism 8 . The lower end is welded with a horizontally arranged leveling frame 11. The lower end surface of the leveling frame 11 is provided with an upper receiving slot 30 for installing the electromagnetic coil 32. The lower part of the coil 32 is provided with a magnetic metal frame 33 that can slide up and down inside the upper receiving slot 30 , a spring 31 is arranged between the upper part of the two sides of the magnetic metal frame 33 and the upper receiving slot 30 , and the lower end of the magnetic metal frame 33 is glued with a spring 31 . The scraping strip 12 for scraping the film horizontally, the scraping and defoaming mechanism 8 between the two turrets 10 are welded with two vertically arran...

Embodiment 3

[0038] The difference between this embodiment and the first embodiment is that the inner side of the pressing mechanism 13 is provided with a pressing frame 14 that can rotate at one end. The upper part of the other end of the frame 14 is provided with a connecting block 26, the upper part of the connecting block 26 is connected with the rotating shaft of the rotating wire sleeve 27, and the rotating wire sleeve 27 is threadedly connected with the lower end of the adjusting frame 34 through the threaded hole at the top thereof, and the adjusting frame 34 is connected with the pressing The top bearing of the mechanism 13 is connected, and the lower part of the pressing frame 14 at one end of the connecting block 26 is provided with a fixing groove 35, and a pressing bar 28 for pressing the film downward is installed inside the fixing groove 35. The inner part of the pressing bar 28 There are elastic metal strips 36 extending therethrough. Both ends of the elastic metal strips 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com