Spray pipe for fixing thermal shrinkage label

A nozzle and label technology, which is applied in the field of nozzles for fixing heat shrinkable labels, can solve the problems of easy blocking of nozzle holes, reduction of high-temperature gaseous spray, and wrinkles, so as to improve the pre-fixing effect and increase the pre- The effect of fixing the area and improving the heat shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

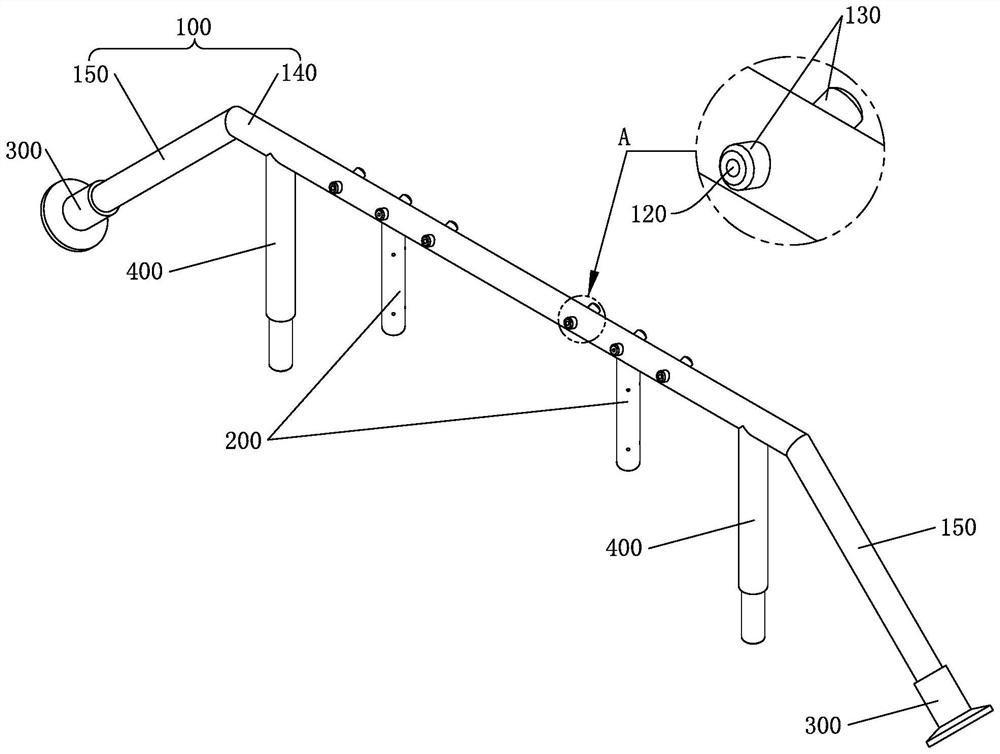

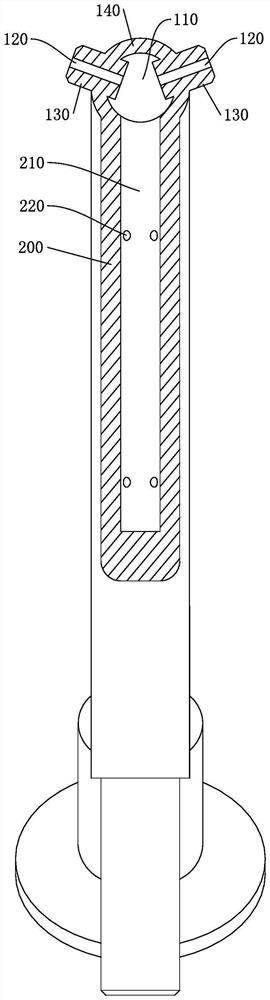

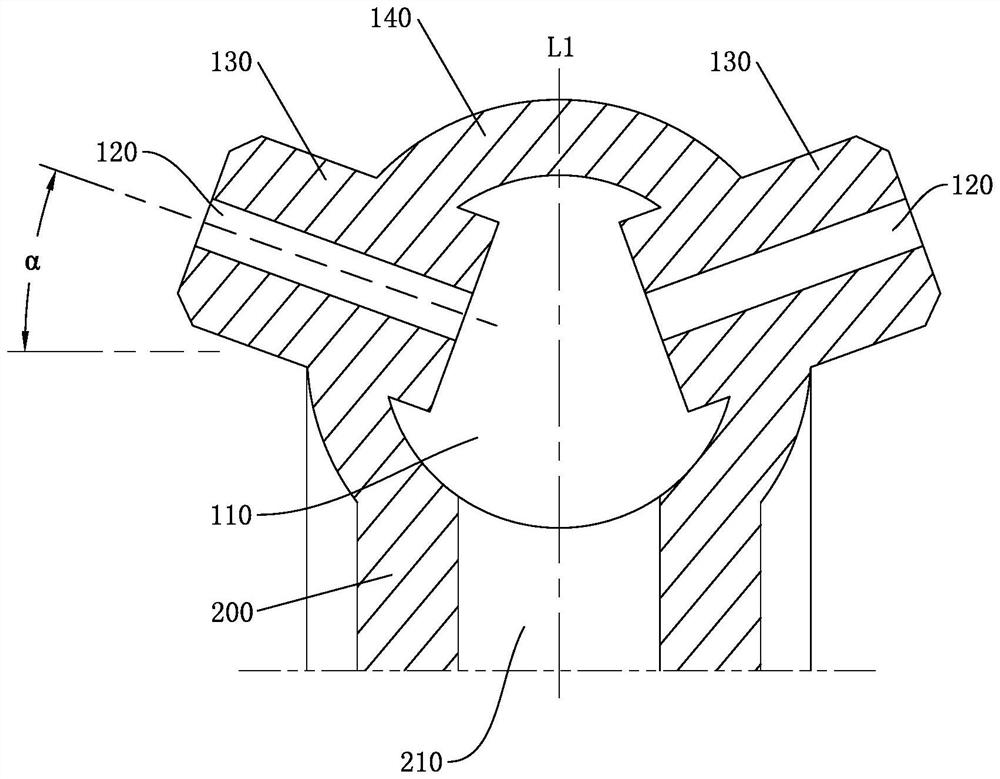

[0030] like Figure 1 to Figure 4 As shown, the first embodiment of the present invention provides a nozzle for fixing a heat shrinkable label, including a main pipe 100 provided with a main channel 110 , and a first air injection hole 120 communicating with the main channel 110 is formed on the main pipe 100 . The main pipe 100 is provided with a boss 130 protruding obliquely upward, and the first air injection hole 120 is provided at the boss 130 . The nozzle also includes a branch pipe 200 connected to the bottom of the main pipe 100. The branch pipe 200 is provided with a branch flow channel 210 and a second air injection hole 220. One end of the branch flow channel 210 is communicated with the main flow channel 110, and the other end is closed. Road 210 is connected.

[0031] An obliquely upwardly protruding boss is set on the main pipe, and the first air injection hole is located at the boss. Because the liquid water droplets formed by cooling are mainly distributed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com