High-hardness impact-resistant ABS composite material and preparation method thereof

A composite material and impact-resistant technology, applied in the field of polymer material preparation, can solve the problems of lower customer satisfaction and poor scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

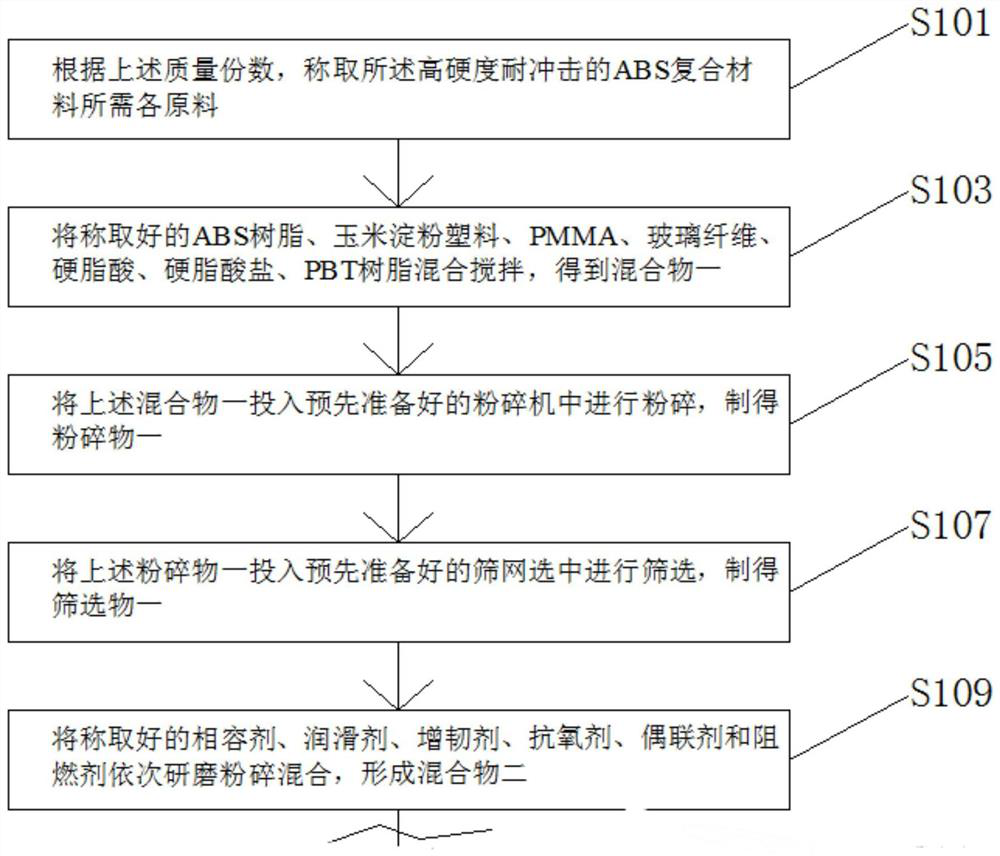

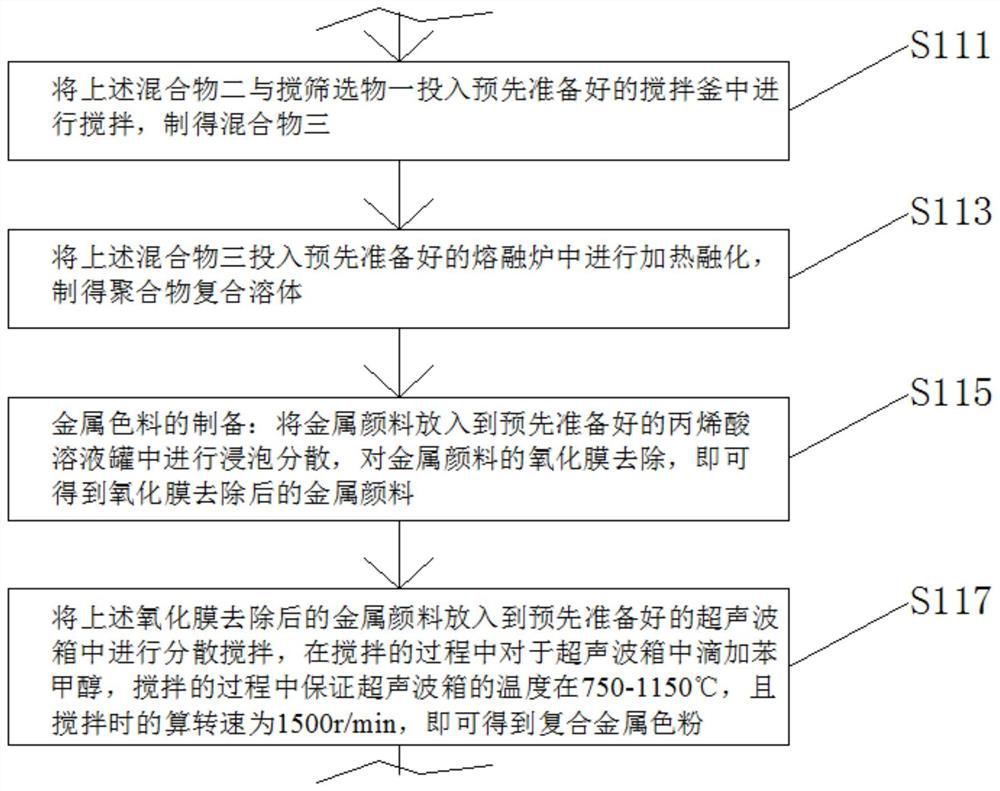

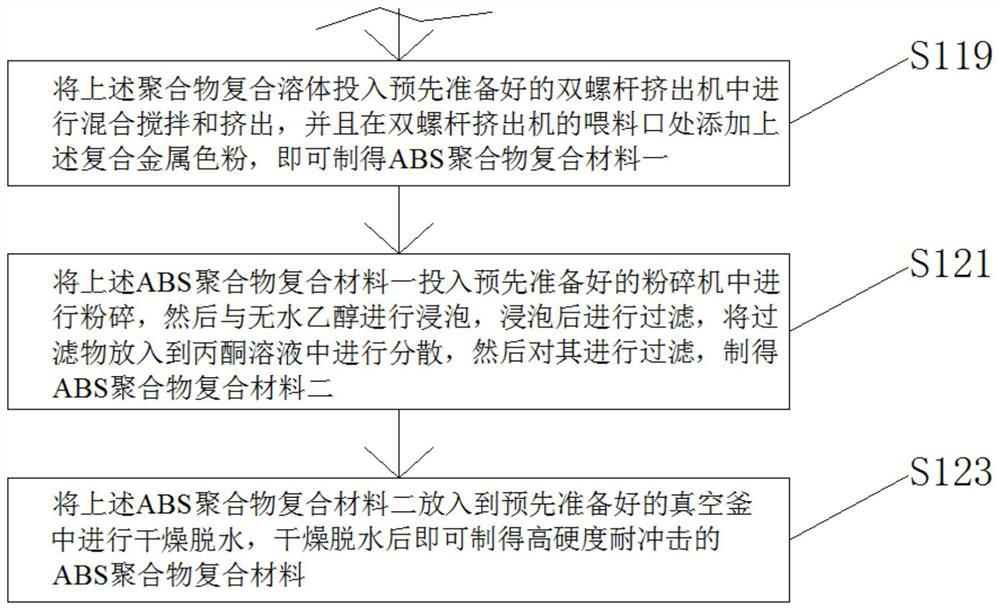

Method used

Image

Examples

Embodiment 1

[0064] A high-hardness impact-resistant ABS composite material, the high-hardness impact-resistant ABS composite material is made of the following raw materials in parts by mass:

[0065] ABS resin 30g, corn starch plastic 10g, PMMA 5g, glass fiber 5g, stearic acid 5g, stearate 2g, PBT resin 5g, metal toner 2g, compatibilizer 2g, lubricant 0.2g, toughening agent 2g , antioxidant 0.2g, coupling agent 0.1g and flame retardant 4g.

[0066] Wherein, the antioxidant includes the following raw material components: one of antioxidant 1010 and antioxidant 1076, antioxidant BHT and antioxidant 2921, and the compatibilizer includes the following raw material components: ABS-g-MAH Or PP-g-MAH etc.

[0067] The flame retardant includes the following raw material components: 3g of brominated anti-flame retardant, 0.5g of phosphorus-based anti-flame retardant and 0.5g of antimony-based anti-flame retardant; the brominated anti-flame retardant is decabromodiphenyl One of ethane and bromina...

Embodiment 2

[0083] A high-hardness impact-resistant ABS composite material, the high-hardness impact-resistant ABS composite material is made of the following raw materials in parts by mass:

[0084] ABS resin 50g, cornstarch plastic 12.5g, PMMA7.5g, glass fiber 7.5g, stearic acid 12.5g, stearate 6g, PBT resin 7.5g, metallic toner 3g, compatibilizer 7g, lubricant 0.5g , toughening agent 5g, antioxidant 0.4g, coupling agent 0.15g and flame retardant 5.5g.

[0085] Wherein, the antioxidant includes the following raw material components: one of antioxidant 1010 and antioxidant 1076, antioxidant BHT and antioxidant 2921, and the compatibilizer includes the following raw material components: ABS-g-MAH Or PP-g-MAH etc.

[0086]The flame retardant includes the following raw material components: 4g of brominated anti-flame retardant, 0.75g of phosphorus-based anti-flame retardant and 0.75g of antimony-based anti-flame retardant; the brominated anti-flame retardant is decabromodiphenyl One of et...

Embodiment 3

[0101] A high-hardness impact-resistant ABS composite material, the high-hardness impact-resistant ABS composite material is made of the following raw materials in parts by mass:

[0102] ABS resin 70g, corn starch plastic 15g, PMMA 10g, glass fiber 10g, stearic acid 20g, stearate 8g, PBT resin 10g, metal toner 4g, compatibilizer 10g, lubricant 0.8g, toughening agent 8g, Antioxidant 0.6g, coupling agent 0.2g and flame retardant 7g.

[0103] Wherein, the antioxidant includes the following raw material components: one of antioxidant 1010 and antioxidant 1076, antioxidant BHT and antioxidant 2921, and the compatibilizer includes the following raw material components: ABS-g-MAH Or PP-g-MAH etc.

[0104] The flame retardant includes the following raw material components: 5 g of brominated flame retardant, 1 g of phosphorus flame retardant and 1 g of antimony flame retardant; the brominated flame retardant is decabromodiphenylethane , one of brominated epoxy resins; the phosphorus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com