Automatic guide deviation rectifying device of rail transportation device

An automatic guidance and rail transportation technology, applied in the field of track deviation correction, can solve problems such as manufacturing, frictional force track levelness error, vehicle body deflection, derailment accidents, etc., and achieve the effects of flexible assembly, simple device structure, and optimized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

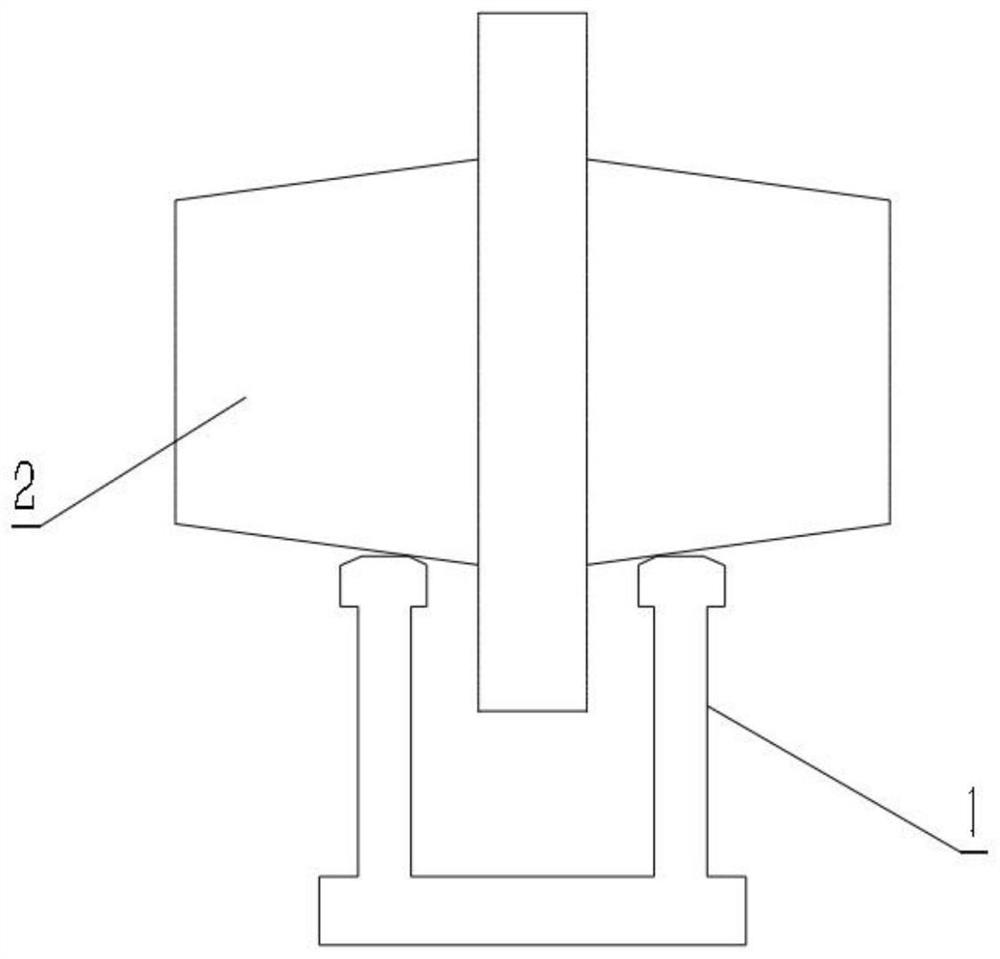

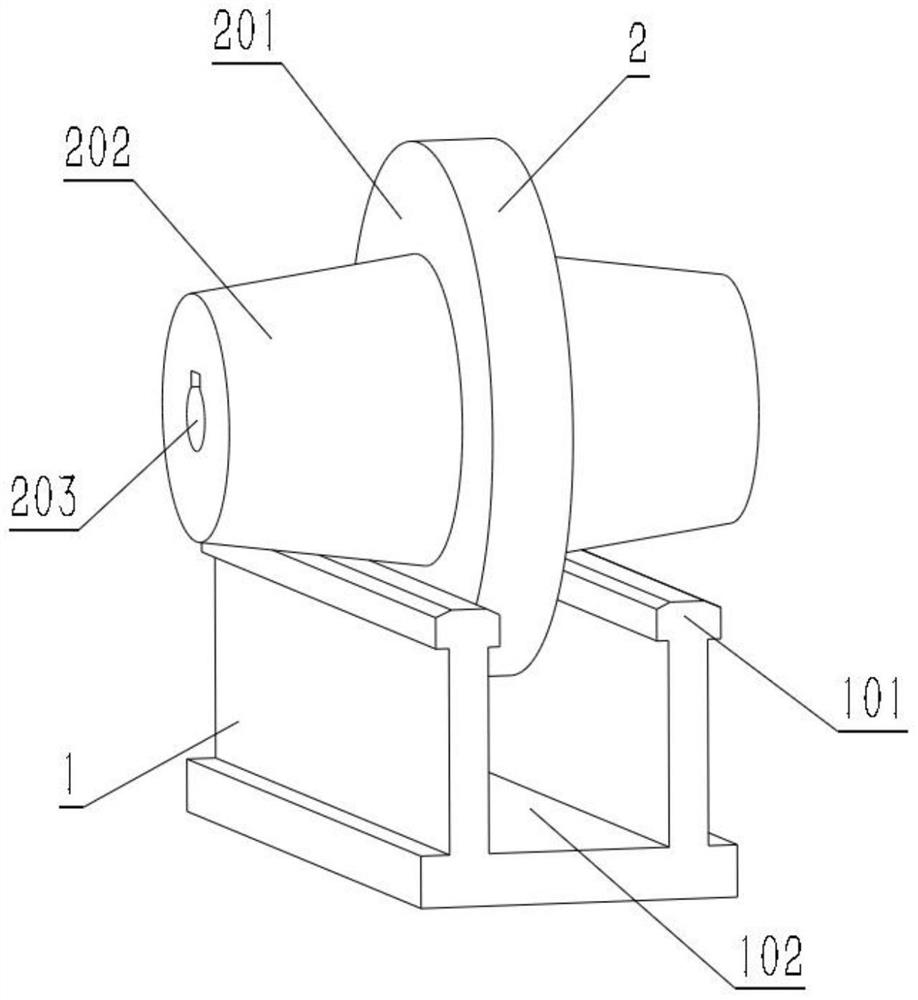

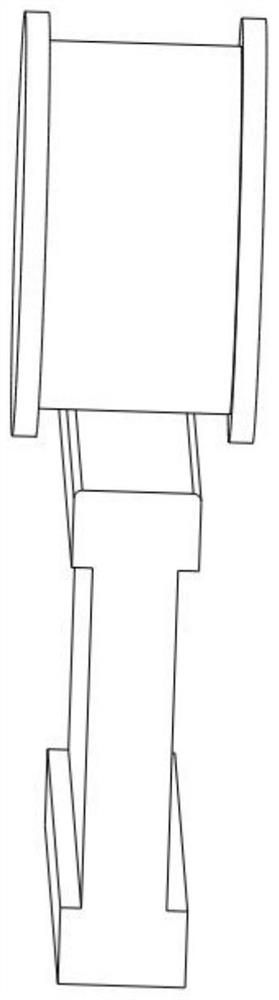

[0012] like Figure 1 to Figure 2 As shown in the figure, an automatic guiding and rectifying device of a rail transportation device of the present invention adopts a technical scheme that includes a U-shaped track 1 and a deviation rectifying wheel 2, and the deviation rectifying wheel 2 is installed on the U-shaped track 1 in a rolling fit. The U-shaped rail 1 is composed of two supporting rails 101 that are parallel and vertically connected to each other. The interval between the supporting rails 101 is a rail groove 102 . 2. It is integrally formed, and the middle ridge 201 of the roller is located in the middle position of the deviation correction wheel 2 in a circular shape. The two sides of the middle ridge 201 of the roller are fixedly connected with a conical roller body 202. Two of the conical roller bodies 202 Symmetrical about the middle ridge 201 of the roller, a shaft mounting hole 203 is formed in the center of the end face of the tapered roller body 202, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com