Hydraulic safety guardrail for hydropower station

A technology for safety guardrails and hydropower stations, which is applied in the directions of hydropower generation, road safety devices, roads, etc., can solve the problems of daily production and life safety hazards of hydropower stations, vehicles falling into river valleys, and high construction difficulty, achieving good application prospects and improving safety. , to ensure the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

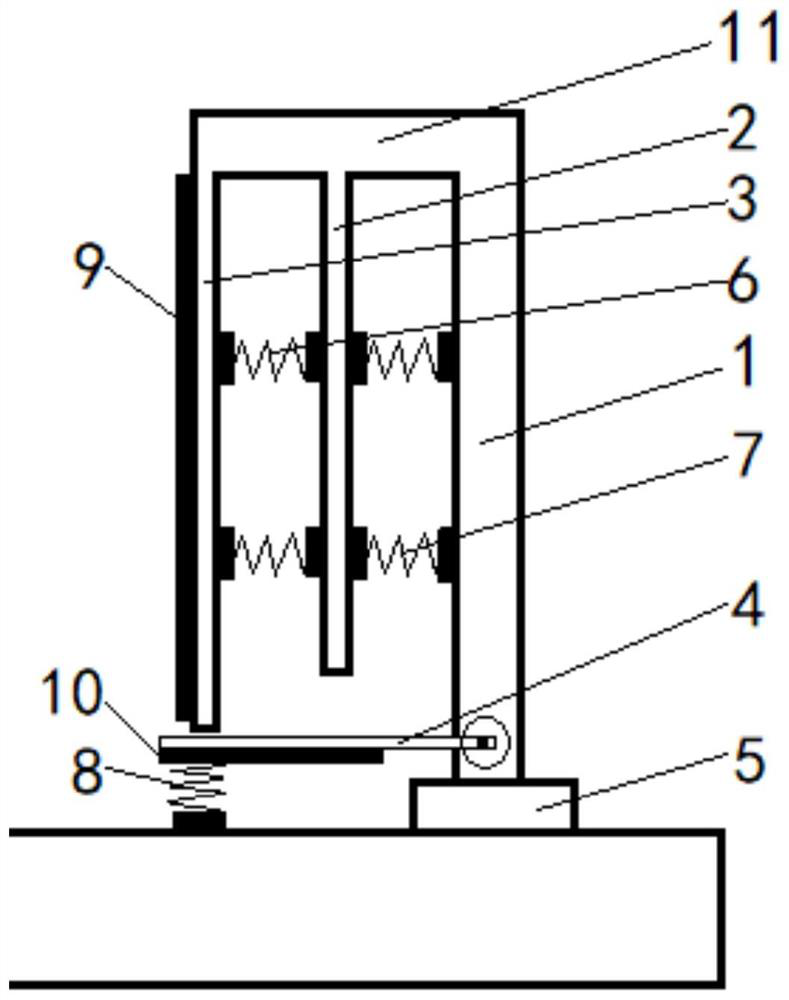

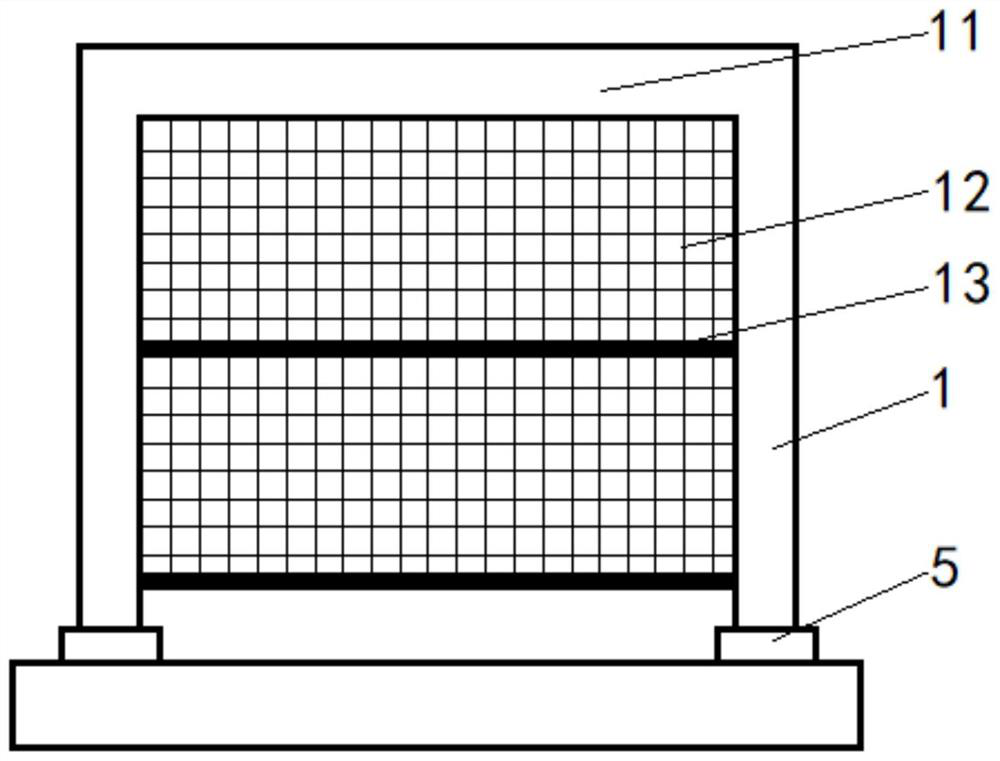

[0030] like figure 1 , the present invention discloses an overall structure of a hydraulic safety guardrail for a hydropower station, including a column 1, an inner buffer plate 2, an outer buffer plate 3, a bottom buffer plate 4, a base 5, a compression spring 8, a top beam 11 and a pocket net 12; the base; 5 is fixed on the ground, the bottom end of the column 1 is fixedly connected with the base 5, the top end of the column 1 is fixedly connected with the top beam 11, the pocket net 12 is arranged between the adjacent columns 1; the inner buffer plate 2 and the outer buffer plate 3 The upper end of the bottom buffer plate 4 is fixedly connected with the top beam 11, and the inner buffer plate 2 is located between the outer buffer plate 3 and the column 1; one end of the bottom buffer plate 4 is hinged to the bottom of the column 1, and the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com