V-shaped steel column and construction method thereof

A construction method and section steel technology, applied in the directions of columns, pillars, pier columns, etc., can solve the problems of instability and collapse of V-shaped steel column installation, complex structure installation accuracy, etc., and achieve the effect of ensuring structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

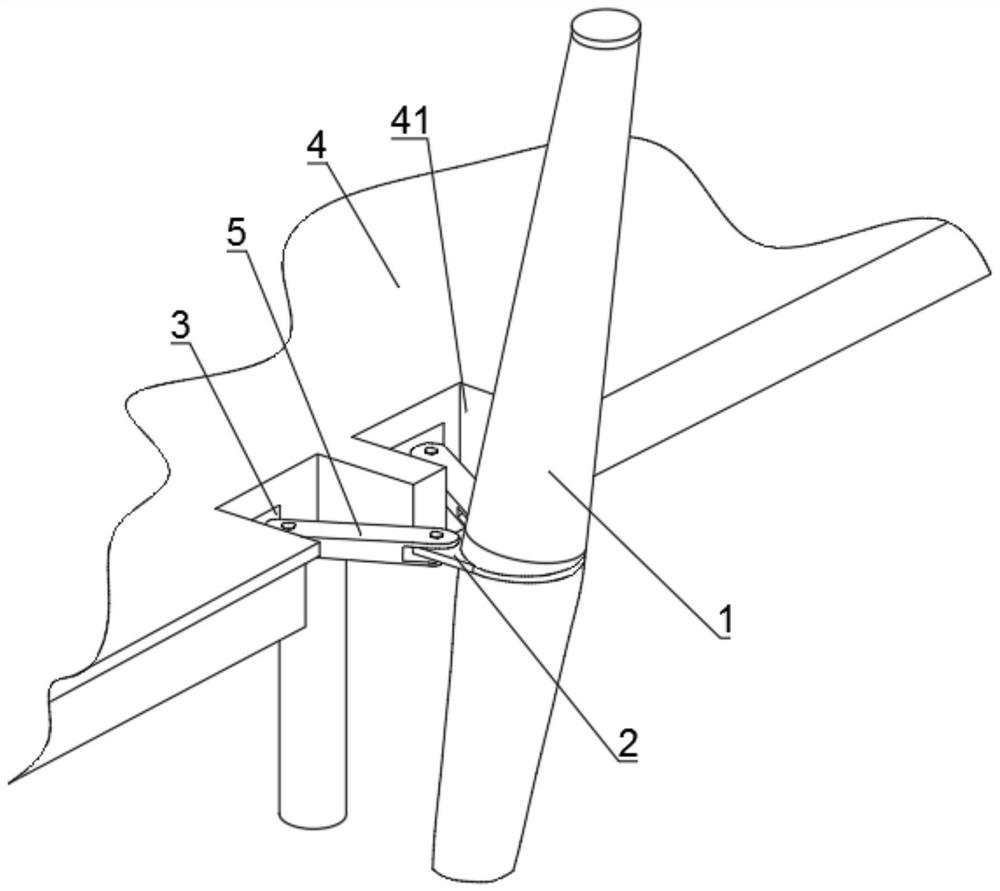

[0040] This embodiment 1 provides a V-shaped steel column, such as Figure 1 to Figure 6 shown, including:

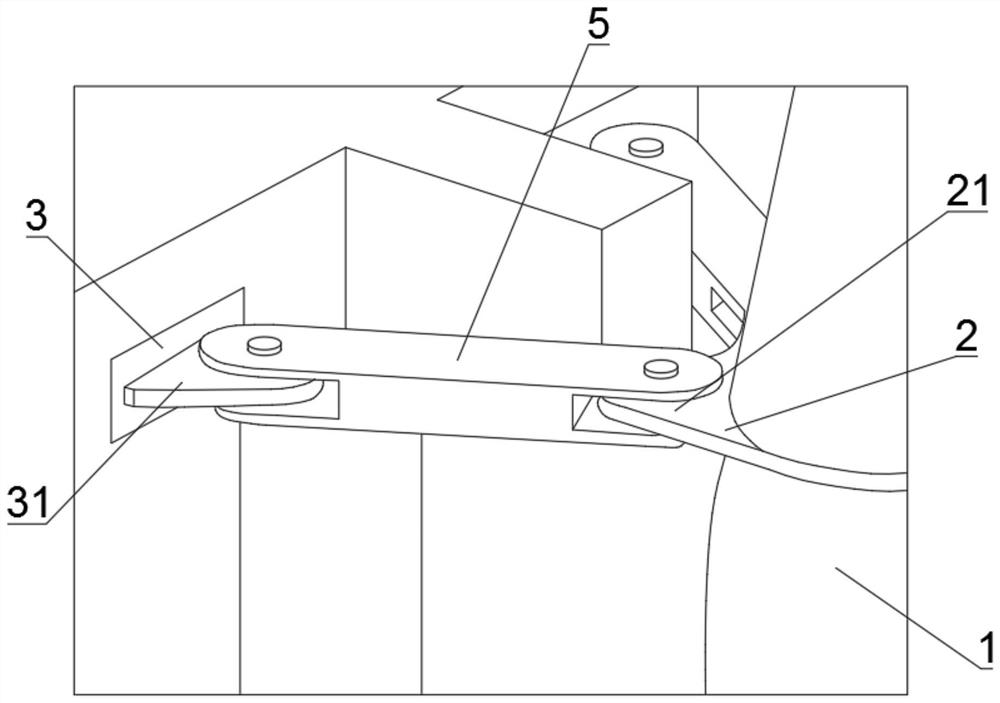

[0041] The first connecting piece 2: the first connecting piece 2 is arranged in the middle of the column body 1, and the first connecting piece 2 includes two first connecting lugs 21 with an included angle;

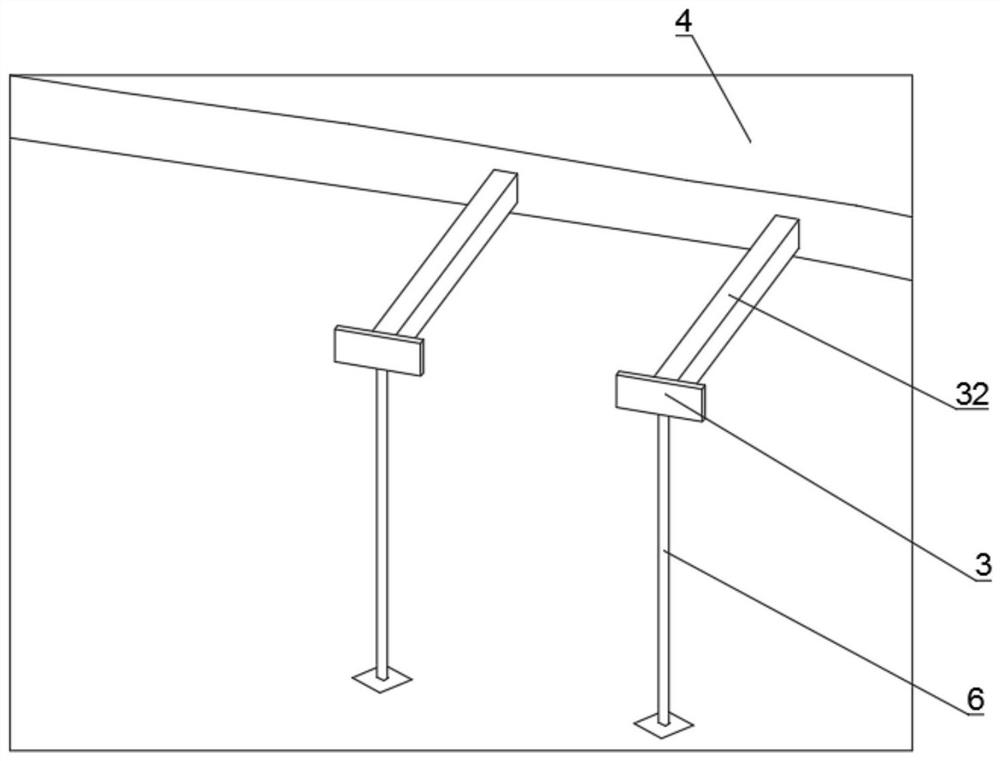

[0042] Pre-embedded panel 3: The pre-embedded panel 3 is pre-embedded on the floor structure 4, and the floor structure 4 is provided with two adjacent pre-embedded grooves 41, and the bottoms of the two pre-embedded grooves 41 are both Pre-embedded boards 3 are pre-embedded, and second connection lugs 31 are fixed on both of the pre-embedded boards 3;

[0043] Second connecting piece 5: the two first connecting pieces 2 are provided with second connecting pieces 5, and the second connecting pieces 5 are respectively pinned to the first connecting lugs 21 and the second connecting lugs 31;

[0044] The top of the column 1 is inclined in the direction away from ...

Embodiment 2

[0049] This embodiment 2 is further optimized on the basis of embodiment 1, such as Figure 5 As shown, a construction method of a V-shaped steel column is provided, which includes the following steps:

[0050] S1: pour the floor structure 4, and pre-embed the embedded board 3 on the floor structure 4;

[0051] S2: Prepare the column body 1, and install the first connector 2 horizontally in the middle of the column body 1 according to the inclination angle of the column body 1;

[0052] S3: Then build a temporary support at the pre-installation position of the column 1;

[0053] S4: After the temporary support is constructed, the column body 1 is hoisted at the pre-installation position, and the column body 1 is supported by the temporary support;

[0054] S5: Then weld the second connection lug plate 31 on the embedded plate 3, and pin the second connection piece 5 to the first connection lug plate 21 and the second connection lug plate 31 respectively;

[0055] S6: The te...

Embodiment 3

[0060] This Embodiment 3 is further optimized on the basis of Embodiment 2, and is used as another implementation manner.

[0061] In this embodiment, a plurality of lifting lugs 7 are arranged in sequence along the length direction of the column body 1 ; in order to adjust the angle of the column body 1 when the column body 1 is hoisted, in this solution, the length direction of the column body 1 is adjusted. A plurality of lifting lugs 7 are arranged on the top in turn, and are hoisted by a crane. Before hoisting, an inverted chain is used to adjust the installation angle of the column body 1, which is convenient for positioning.

[0062] In this embodiment, the temporary support includes a support frame body 8, the support frame body 8 is fixed on the ground, and a sliding positioning template 9 is provided on the top of the supporting frame body 8, and the sliding positioning template 9 includes a positioning platform 91 and The sliding plate 92, the positioning platform 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com