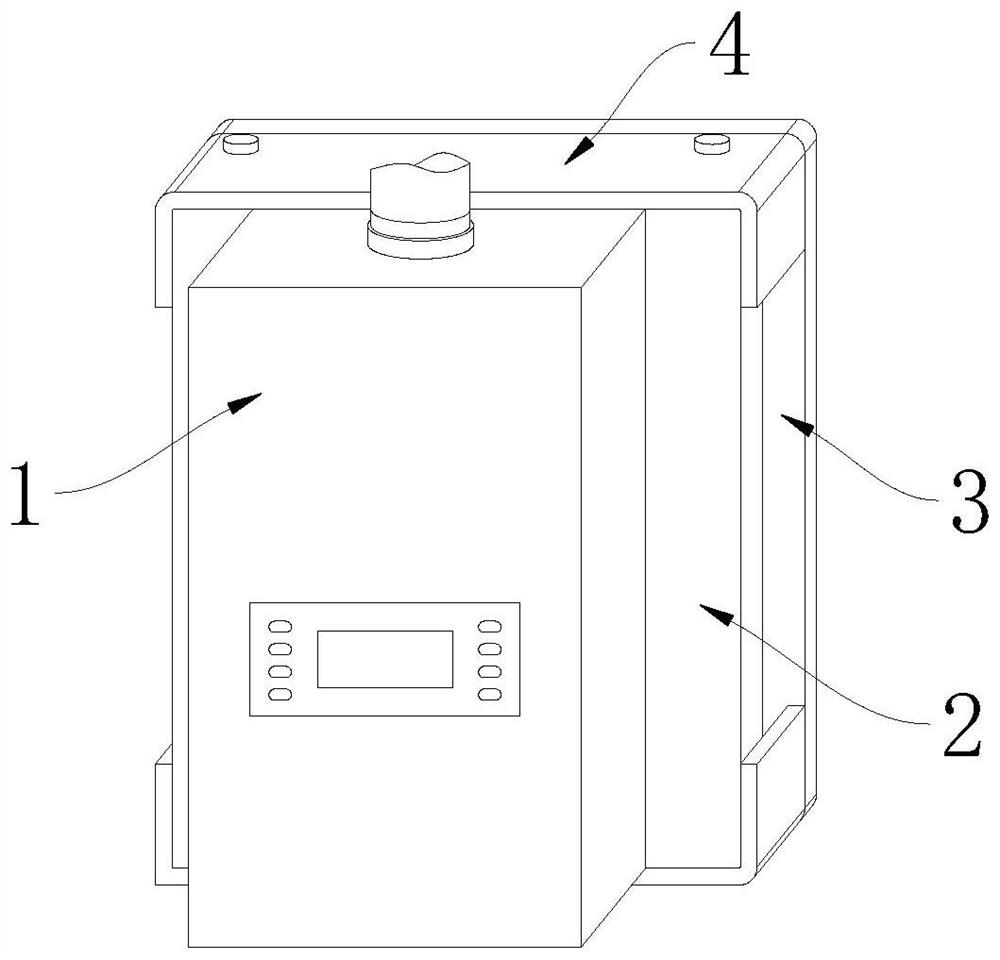

Gas wall-hanging stove

A gas-fired wall-hung boiler and a mounting plate technology, applied in the field of wall-hung boilers, can solve the problems of poor applicability, affecting the efficiency of disassembly and assembly, complicated operation, etc., achieving the effects of good applicability, avoiding secondary damage and large lifting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

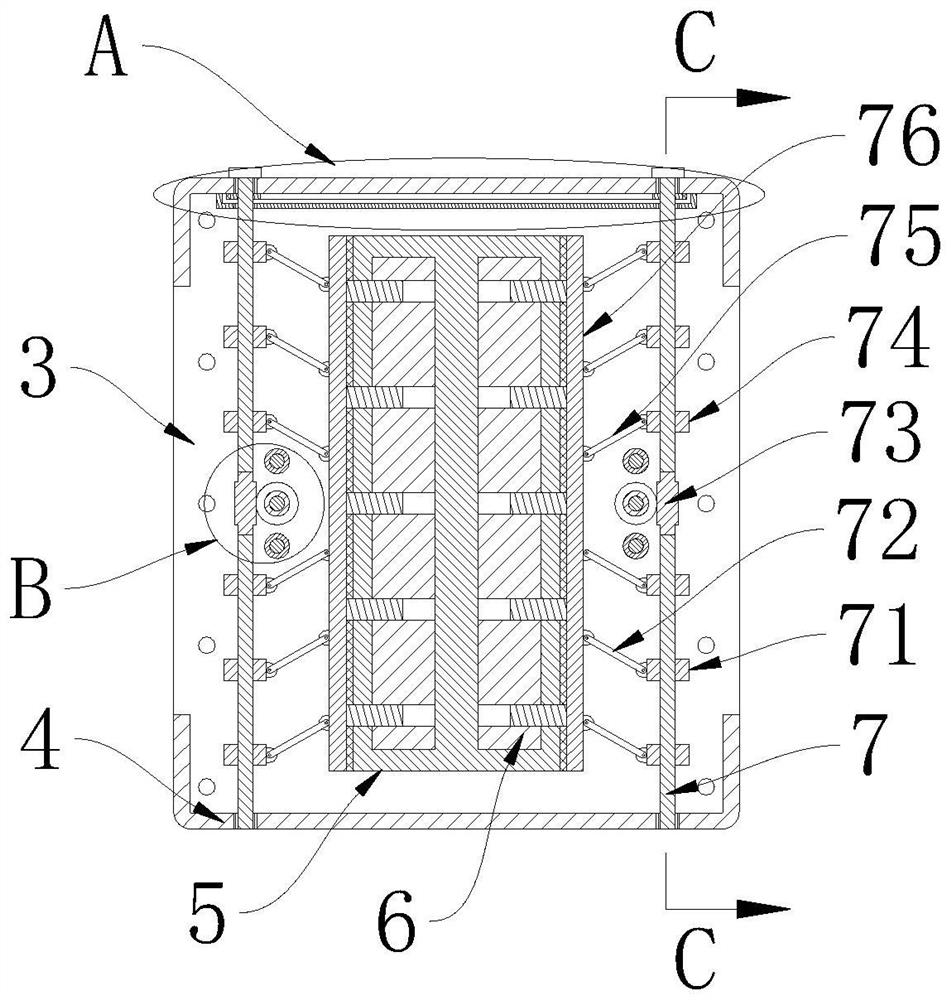

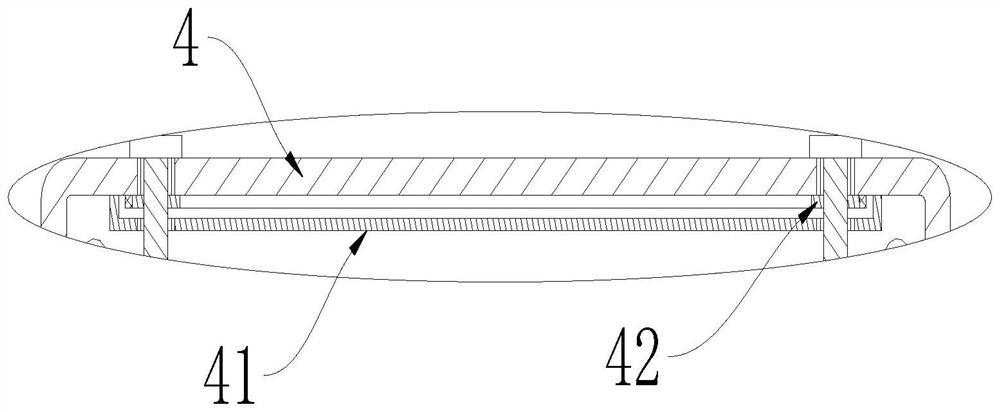

[0043] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS First, the fixing plate 3 is fixed to the pre-installation position on the wall by means of expansion bolts, then the installation plate 2 is moved to the front side of the fixing plate 3, and the plug board 6 at the rear end of the installation plate 2 is placed on the mounting seat The front end of the slot 51 on the 5, and then push the installation board 2 backward, and then insert the board 6 into the slot 51 to realize the wall-mounted installation of the main body 1 of the gas wall-hung boiler. At this time, the first L-shaped card board 711 and the second The L-shaped clips 741 are respectively installed in the longitudinal part of the second L-shaped groove 23 and the longitudinal part of the first L-shaped groove 22, and then a bidirectional screw 7 is rotated, so that the corresponding sprocket 42 is rotated, and the chain And under the action of the two sprockets 42, the two bidirectional screws 7 are rotated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com