Sheet sterilization device and filling production line

A sterilizing device and sheet technology, applied in packaging sterilization, water supply device, drying gas layout, etc., can solve the problems of large storage space, large length, occupation, etc., to increase the drying area and reduce the overall size , Increase the effect of sterilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

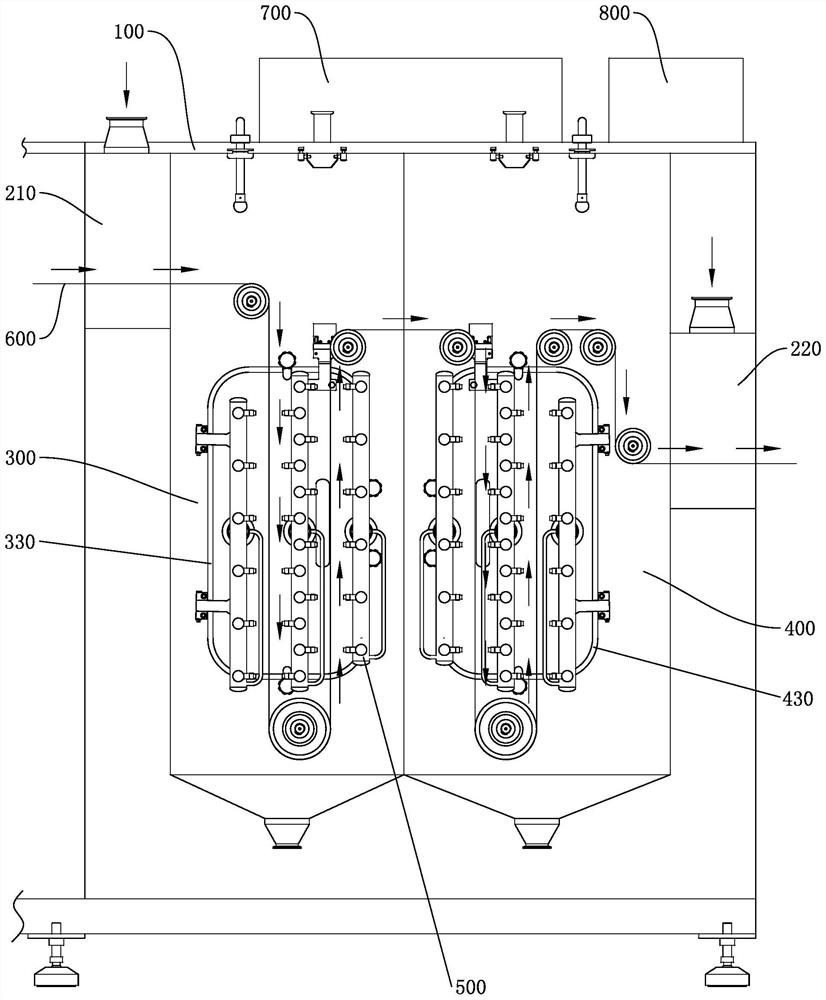

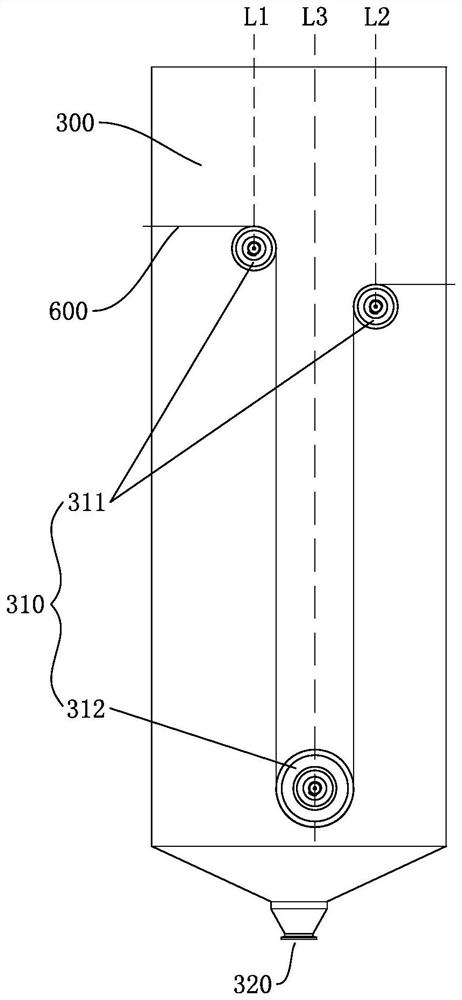

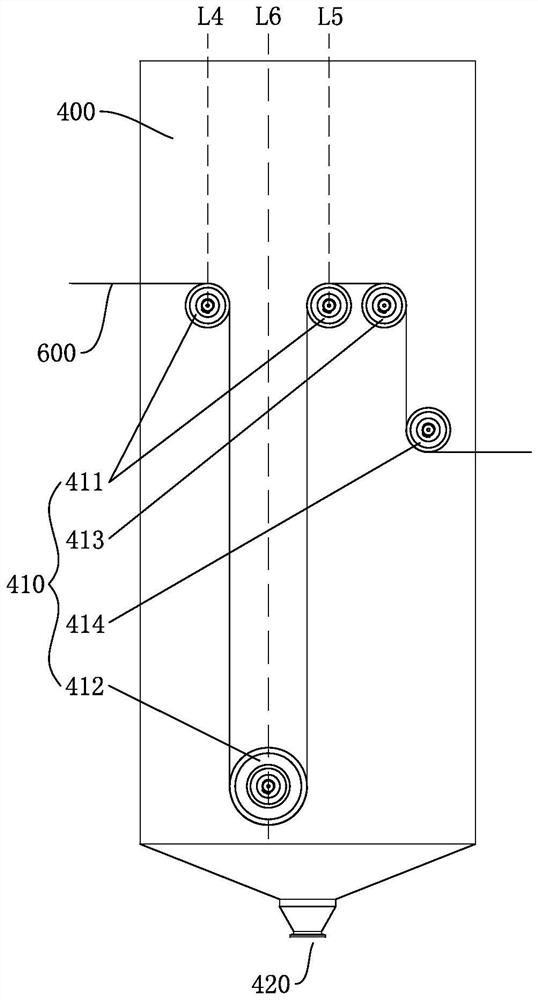

[0032] like Figure 1 to Figure 4 As shown in the figure, a sheet sterilization device provided by the first embodiment of the present invention includes a hood 100, and also includes a feed-side positive pressure barrier chamber 210 and a sterilization chamber 300 that are sequentially distributed in the hood 100 along the feeding direction. , the drying chamber 400 and the positive pressure barrier chamber 220 on the discharge side. The sterilization chamber 300 is provided with a first guide mechanism 310 for horizontally outputting the horizontally input sheet 600 after vertical movement in the sterilization chamber 300. The drying chamber 400 There is a second guide mechanism 410 for horizontally outputting the horizontally input sheet 600 in the drying chamber 400 after vertical movement. The moving direction of the sheet 600 in the sterilization chamber 300 and the drying chamber 400 is perpendicular to the sheet 600 feed direction.

[0033] Through the first guiding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com