Electrolytic sterilizing apparatus for ship ballast water

A technology of sterilization device and ballast water, which can be used in water treatment devices, transportation and packaging, water/sewage treatment, etc., and can solve problems such as poor marine ecosystems and impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now, according to the preferred embodiment of the present invention, the electrolytic sterilization device for ship's ballast water will be described in detail with reference to the accompanying drawings.

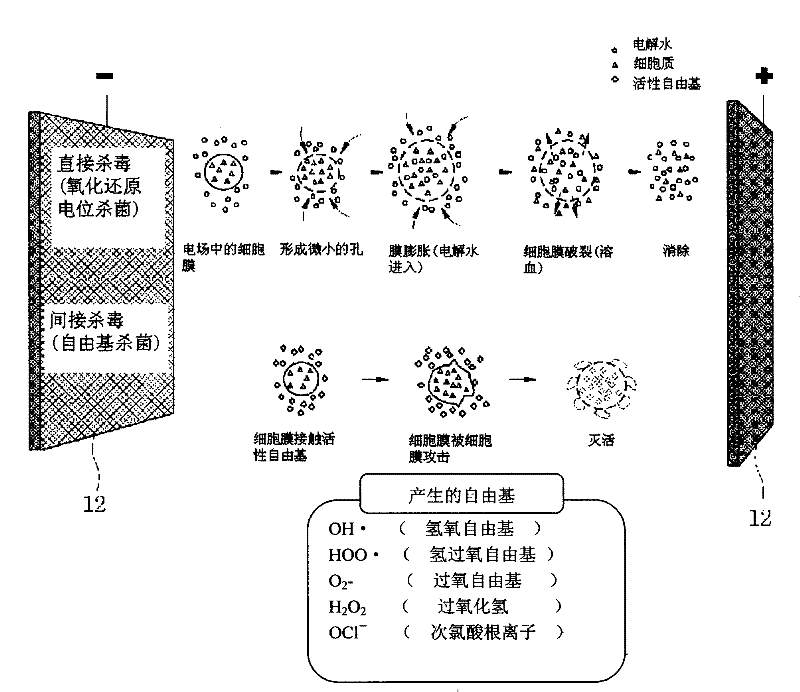

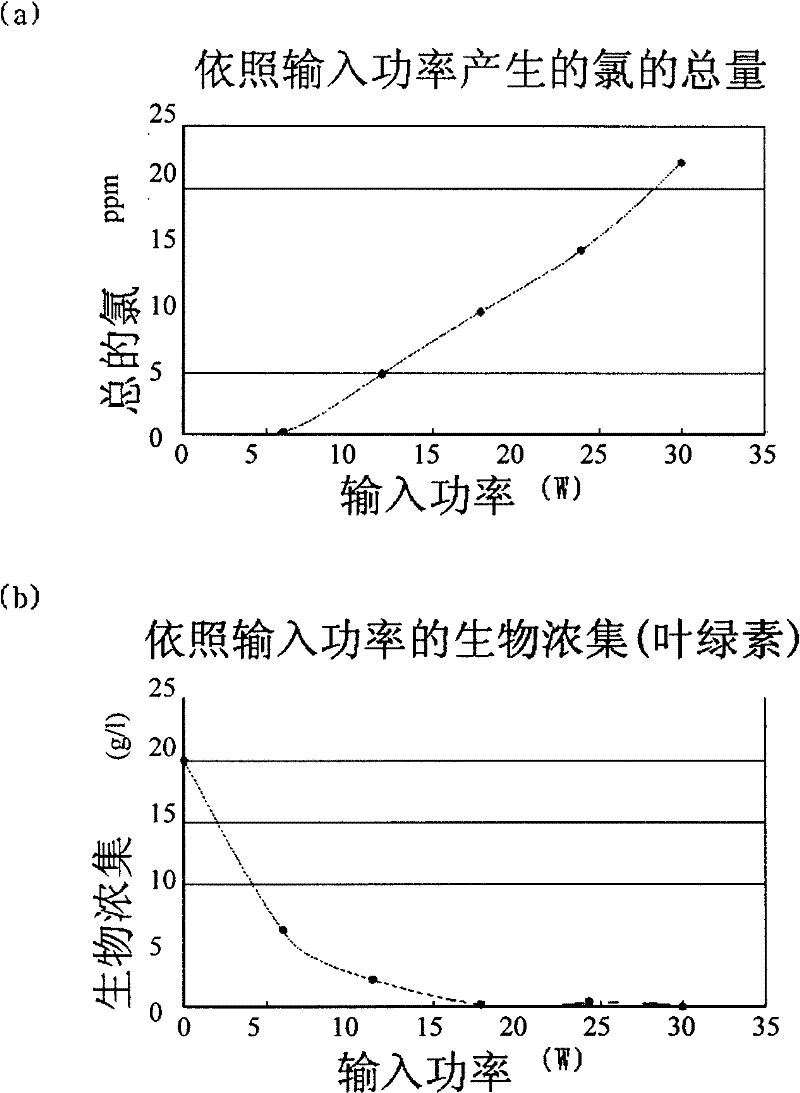

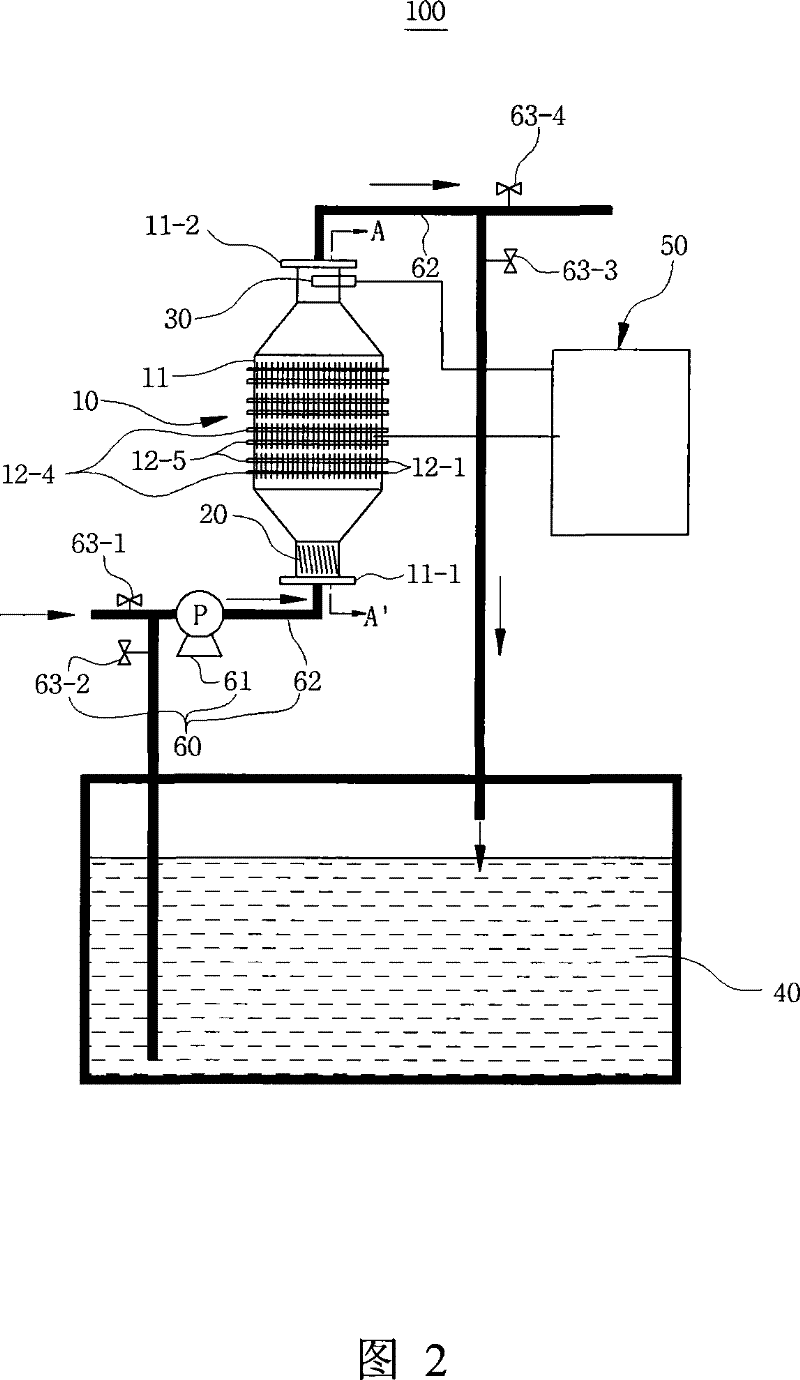

[0022] figure 1 It is a schematic diagram of the sterilization principle of the electrolytic sterilization device according to the present invention, figure 2 is a schematic diagram of an electrolytic sterilization device for ship ballast water according to the present invention, Figure 3A and 3B are respectively a plan view and a perspective view of a schematic parallel electrode pair according to an embodiment of the present invention, Figure 4 yes figure 2 An enlarged view of the electrolysis module shown in, Figure 5 is along figure 2 The vertical section of the line A-A', Figure 6 yes Figure 4 A detailed view of the electrode pair shown in, Figure 7A and 7B are respectively plan views of mesh electrodes and plate electrodes according to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com