Preparation method of termite-proof cable

A technology for preventing termites and cables, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as easy loss and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

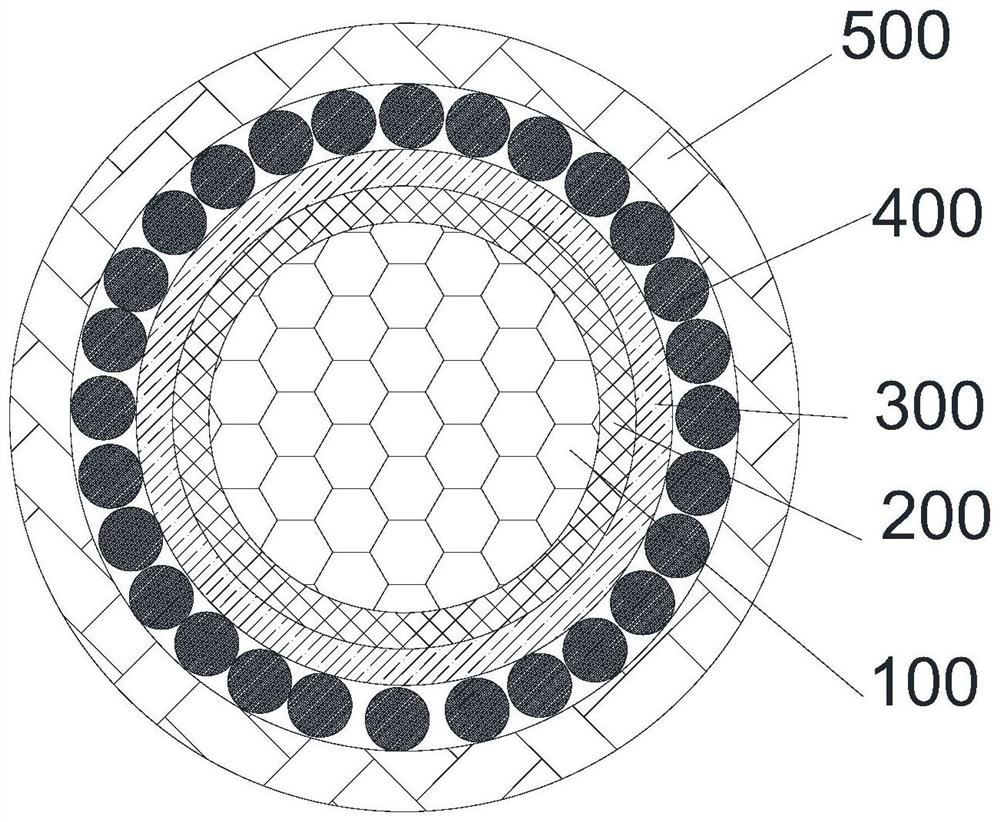

[0074] A kind of anti-termite cable preparation method, provided with a cable core 100, an insulation layer 200, an inner sheath layer 300 prepared by the poison ant sheath material, an armor layer 400 and an outer sheath layer 500 prepared by the ant repellent sheath material, in accordance with the order from the center to the outside, sequentially set up with a cable core 100, an inner sheath layer 300, an armor layer 400 and an outer sheath layer 500, such as Figure 1 。

[0075] The ant repellent jacket contains type III PVC resin powder, nodyl terephthalate, epoxy soybean oil, polyethylene wax, stabilizer, nano calcium carbonate, stearic acid, impact modifier, ant repellent A and anti-termite microcapsules.

[0076] The termite inner sheath contains polyvinyl chloride with a degree of polymerization of 1600 to 2500, diisonyl phthalate, epoxy soybean oil, polyethylene wax, stearic acid, nano calcium carbonate and ant agent.

[0077] Among them, the contents of the anti-termite...

Embodiment 2

[0116]A kind of anti-termite cable preparation method, provided with cable core 100, insulation layer 200, 300 inner sheath layer prepared by poisonous ant sheath material, armor layer 400 and outer sheath layer 500 prepared by ant repellent sheath material, in accordance with the order from the center to the outside, sequentially set up with cable core 100, inner sheath layer 300, armor layer 400 and outer sheath layer 500.

[0117] The ant repellent jacket contains type III PVC resin powder, nodyl terephthalate, epoxy soybean oil, polyethylene wax, stabilizer, nano calcium carbonate, stearic acid, impact modifier, ant repellent A and anti-termite microcapsules.

[0118] The termite inner sheath contains polyvinyl chloride with a degree of polymerization of 1600 to 2500, diisonyl phthalate, epoxy soybean oil, polyethylene wax, stearic acid, nano calcium carbonate and ant agent.

[0119] Among them, the contents of the anti-termite microcapsule are ant repellent B. The shell of th...

Embodiment 3

[0151] A kind of anti-termite cable preparation method, provided with cable core 100, insulation layer 200, 300 inner sheath layer prepared by poisonous ant sheath material, armor layer 400 and outer sheath layer 500 prepared by ant repellent sheath material, in accordance with the order from the center to the outside, sequentially set up with cable core 100, inner sheath layer 300, armor layer 400 and outer sheath layer 500.

[0152] The ant repellent jacket contains type III PVC resin powder, nodyl terephthalate, epoxy soybean oil, polyethylene wax, stabilizer, nano calcium carbonate, stearic acid, impact modifier, ant repellent A and anti-termite microcapsules.

[0153] The termite inner sheath contains polyvinyl chloride with a degree of polymerization of 1600, diisononyl phthalate, epoxy soybean oil, polyethylene wax, stearic acid, nano calcium carbonate and ant agent.

[0154] Among them, the contents of the anti-termite microcapsule are ant repellent B. The shell of the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com