Method and device for determining profile of frame recess

A technology of frames and equipment, applied in the field of glasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

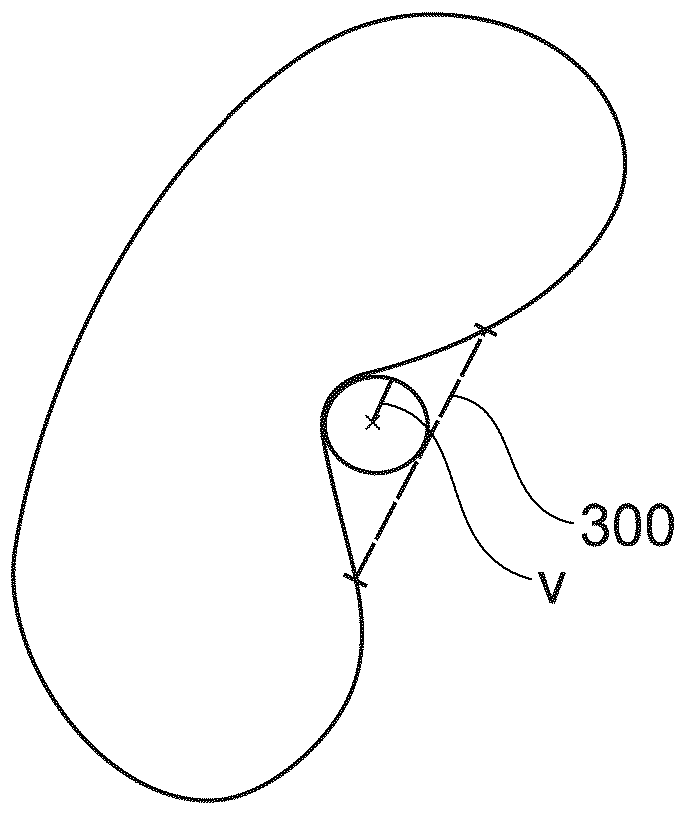

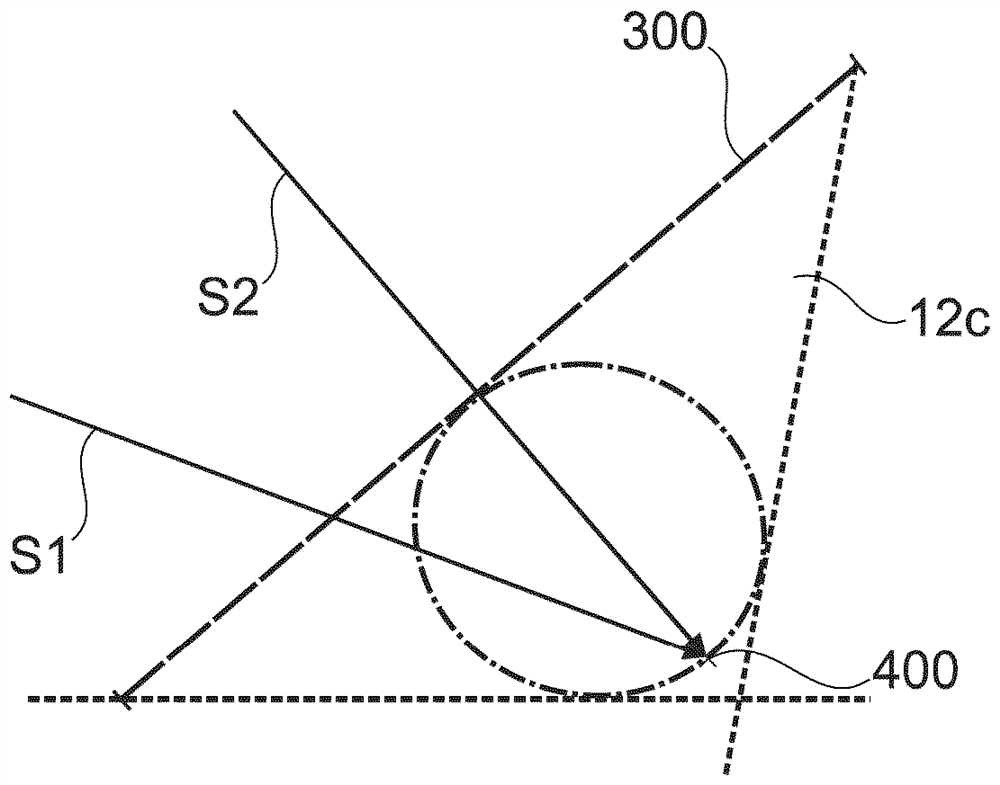

[0089] Figure 1A and Figure 1B respectively in side view ( Figure 1A ) and floor plans ( Figure 1B ) shows a schematic diagram of an apparatus 10 for contactless determination of the profile of a frame groove in a rim of a spectacle frame 12 according to a preferred embodiment.

[0090] The apparatus 10 includes lighting means 14 in the form of a display according to the illustrated embodiment. For example, the display may comprise a commercially available computer display or may be so designed. Illumination device 14 is designed to provide directional illumination to the rim of eyeglass frame 12 as transmitted light illumination along the entire circumference of rim 12a. In this case, the spectacle frame 12 includes two temples 12a and two temples 12b. According to other embodiments, the apparatus 10 may include other illumination devices and / or light sources designed to provide incident light illumination such that light is incident on the eyeglass frame 12 from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com