Method and device for the automated identification of bobbin tubes

An automatic identification and bobbin technology, which is used in transportation and packaging, textiles and papermaking, transportation of filamentous materials, etc., can solve problems such as inability to distinguish and achieve the effect of eliminating identification errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

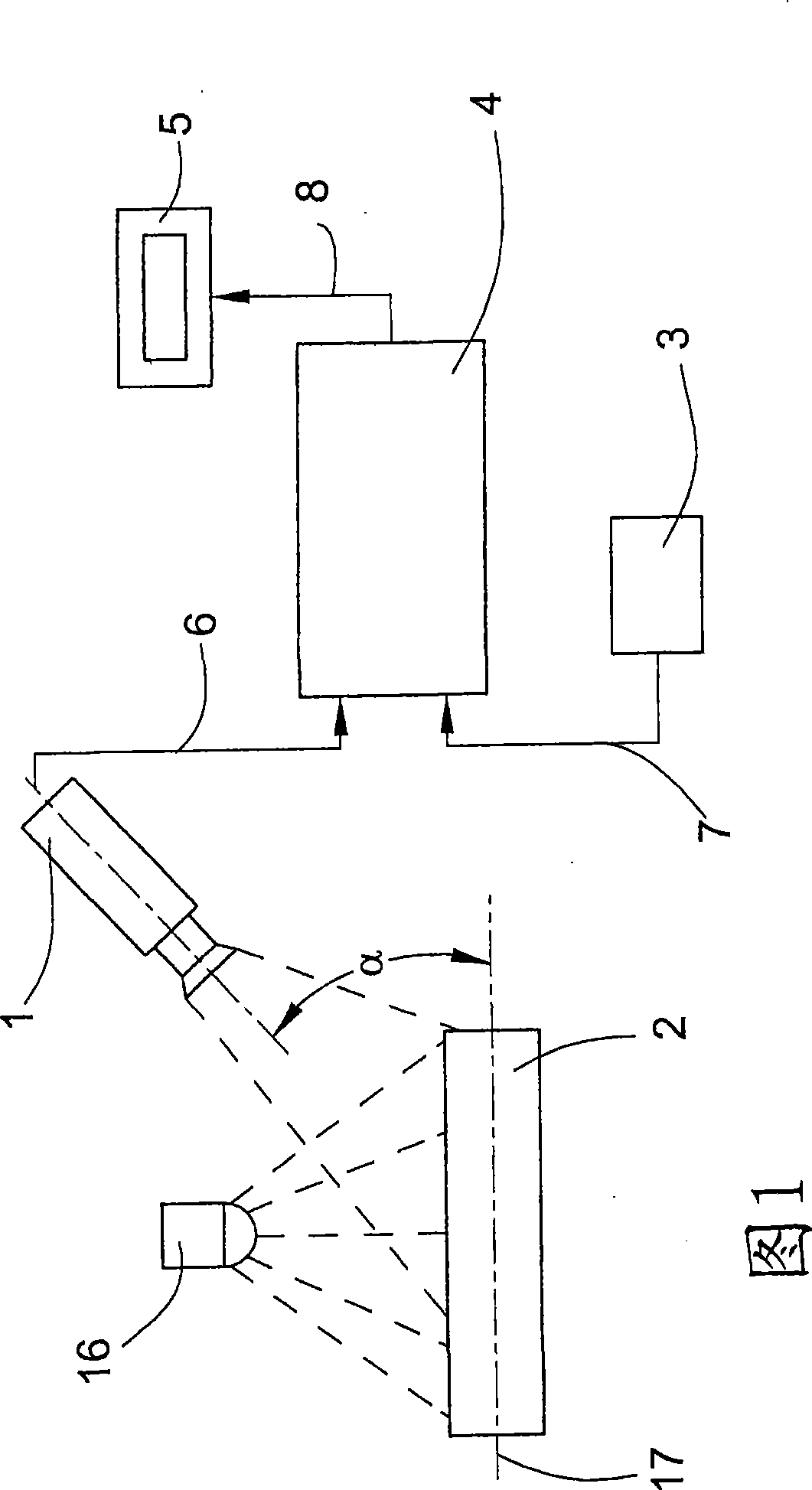

[0039] FIG. 1 schematically shows a device for carrying out the method according to the invention. The device mainly comprises a CCD camera 1 connected to an image processing device 4 via a signal line 6 .

[0040] The memory 3 is also connected to the image processing device 4 , for example via a signal line 7 , and the display device 5 is also connected to the image processing device 4 via a signal line 8 .

[0041] In addition, a light source 16 is preferably provided in order to properly illuminate the bobbin 2 to be identified, which light source 16 is preferably a constant diffuse light source. As shown in FIG. 1 , the CCD camera 1 is preferably arranged at an angle α with respect to the bobbin axis 17 of the bobbin 2 to be detected, so that in the area of the bobbin 2 the viewing field (blickfeld) that can be detected by the camera 1 includes the bobbin at least half the length.

[0042] However, the image processing means 4 and the associated memory 3 and display m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com