Simple paste for measuring surface deformation of material and production method thereof

A surface deformation and simple technology, applied in the direction of measuring devices, chemical instruments and methods, instruments, etc., can solve the problems of less grid/lattice, large grid/lattice size, smaller size, etc., to improve the processing speed. And the effect of precision, mature production technology, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

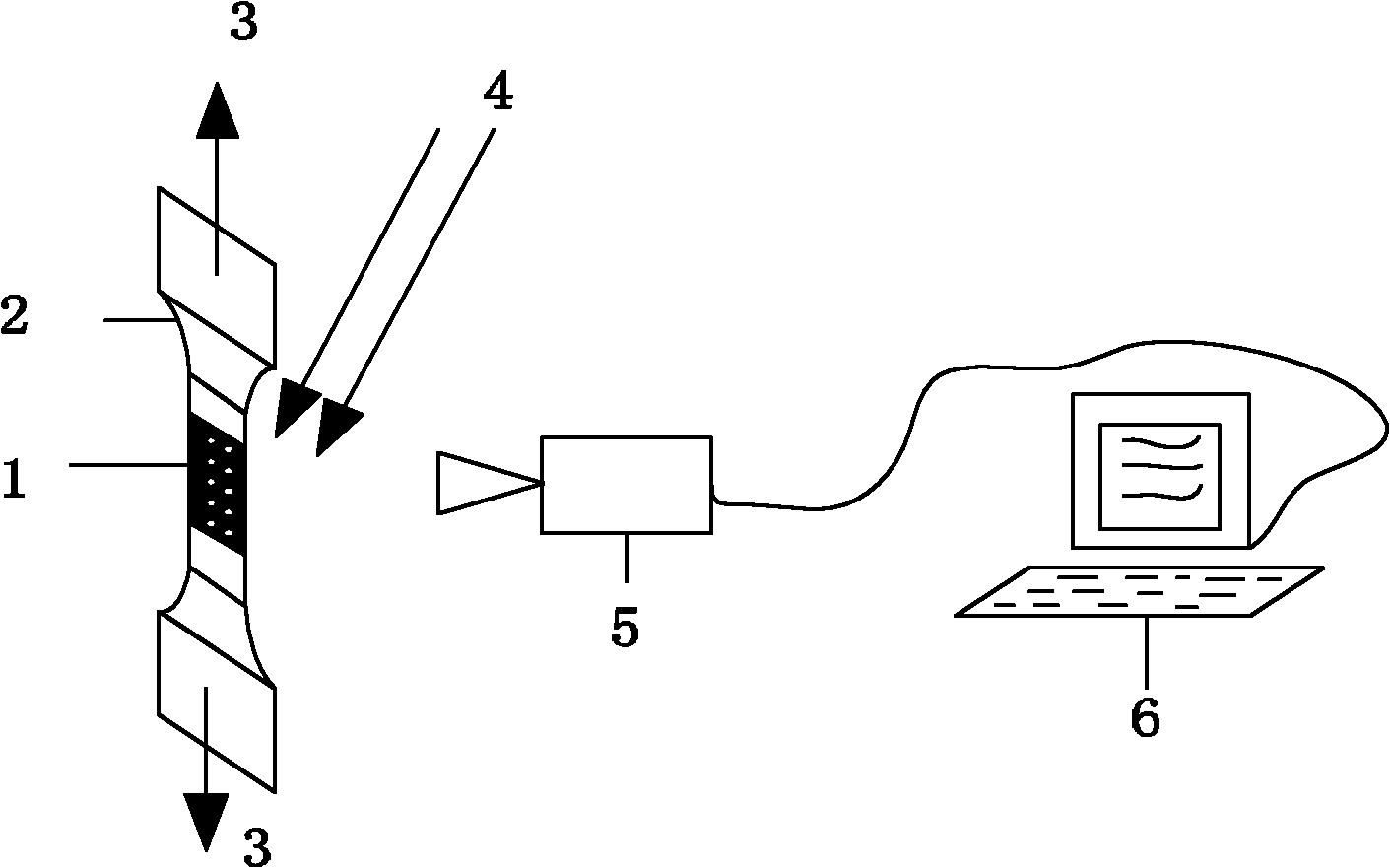

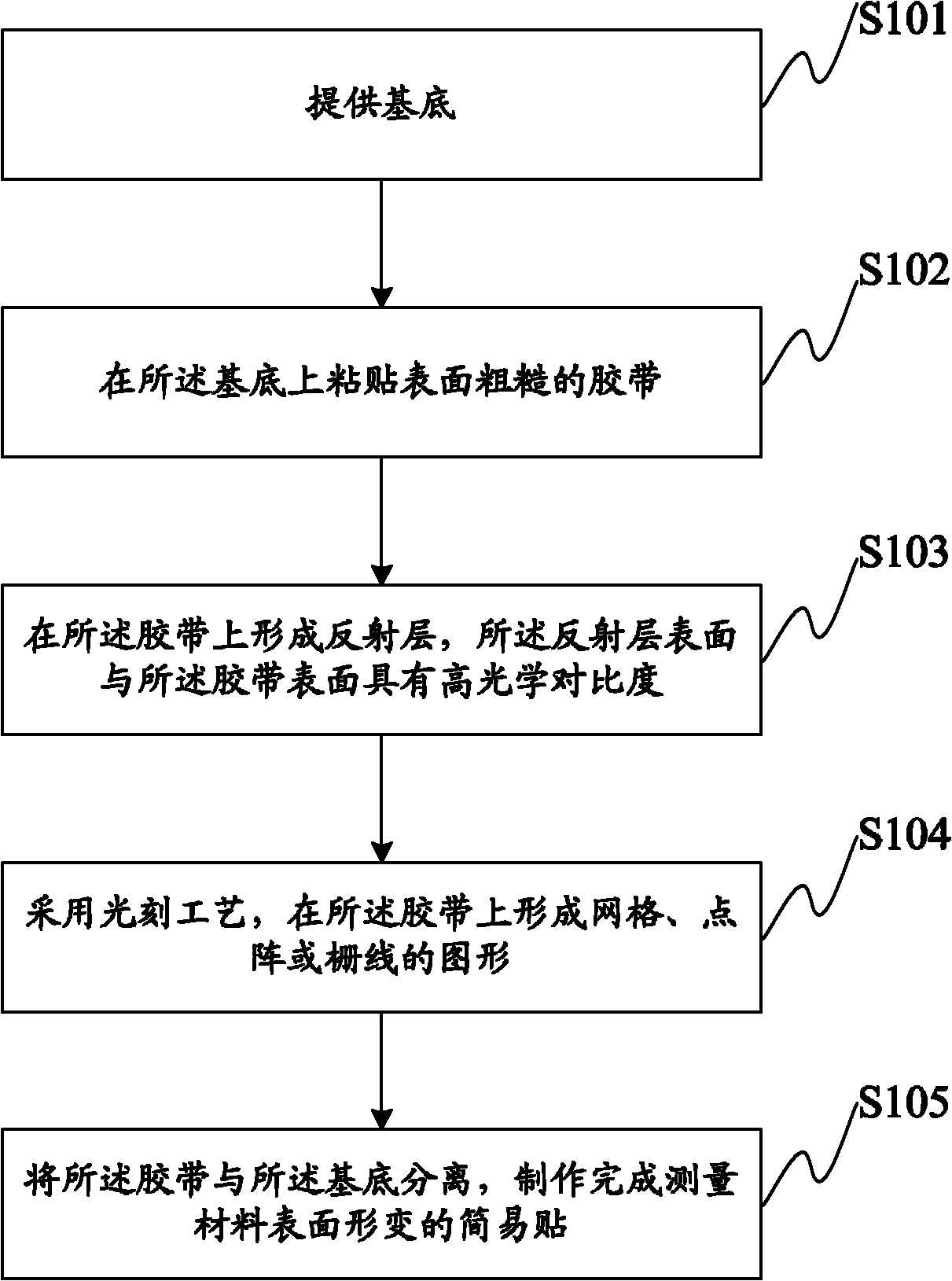

[0058] This embodiment discloses a method for making a simple sticker for measuring the surface deformation of a material. The flow chart of the method is as follows figure 2 As shown, the cross-sectional diagram of each step of the method is shown in Figure 3-Figure 9 shown, including the following steps:

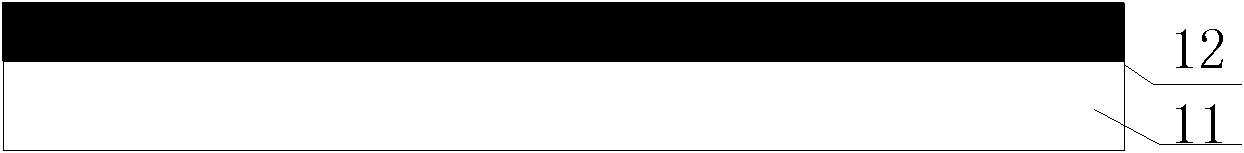

[0059] Step S101: providing a substrate 11;

[0060] see image 3 , the main function of the base 11 is to make the surface of the adhesive tape to be pasted smooth, so as to make grid / dot matrix etc. on the surface of the adhesive tape. Therefore, the base 11 only needs to be a flat base. Planar glass substrate, of course, other planar substrates can also be used.

[0061] Step S102: Paste an adhesive tape 12 with a rough surface on the base 11, such as image 3 shown;

[0062] The side of the adhesive tape 12 that is in contact with the base 11 can have adhesive or the like, so that after the adhesive tape 12 is laid flat, it can be pasted together with the base 1...

Embodiment 2

[0079] The flow chart of the method for making the simple sticker for measuring the surface deformation of the material disclosed in this embodiment is as follows Figure 10 As shown, the cross-sectional diagram of each step is shown in Figure 3-Figure 9 As shown, the difference between this embodiment and the previous embodiment is that step S205 is added on the basis of the previous embodiment: after removing the photoresist, on the adhesive tape with the pattern of grid, dot matrix or grid line Form protective layer 15, to avoid that the figure of described grid, dot matrix or grid line comes off, as Figure 9 shown.

[0080] Specifically, the chrome grid / dot matrix can be fixed on the PVC tape by spraying transparent paint on the PVC tape with chrome lattice, so as to avoid the chrome grid / dot matrix under external friction during use. The thickness of the transparent paint is about 10nm, and the thickness should be uniform, so as not to affect the measurement results. ...

Embodiment 3

[0094] Corresponding to the above method embodiments, this embodiment discloses a simple sticker for measuring the surface deformation of a material made by using the methods of the above two embodiments. The simple sticker includes:

[0095] A tape with a rough surface, preferably a PVC tape with a black surface;

[0096] The pattern of the grid, dot matrix or grid line arranged on the adhesive tape, the graphic surface of the grid, dot matrix or grid line has high optical contrast with the surface of the adhesive tape, and the grid, dot matrix or grid line The production of graphics such as lines is preferably metallic chrome.

[0097] In addition, the simple sticker also includes a protective layer covering the graphics of the grid, dot matrix or grid lines, preferably transparent paint, so as to prevent the graphics of the grid, dot matrix or grid lines from falling off under external friction.

[0098] In this embodiment, the simple sticker consisting of PVC tape and chr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com