A kind of micron powder material controllable classification air sieve and screening method

A technology of powder material and airflow sieve, which is used in powder engineering, pneumatic conveying, screening technology, and fluidized bed fields to avoid easy blockage and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

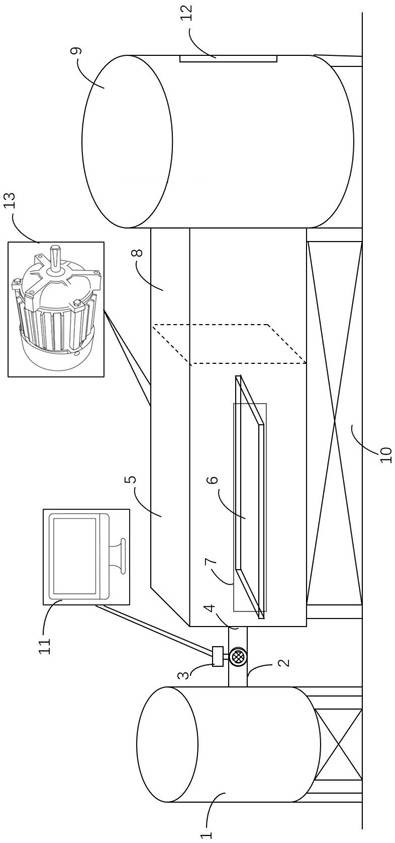

[0041] like figure 1 As shown, this embodiment proposes a controllable grading airflow sieve for micron-level powder materials, including a high-pressure air source 1 (the high-pressure air source 1 refers to an air source whose pressure is greater than atmospheric pressure, generally higher than 5 atmospheric pressure can be used high-pressure gas source 1), gas transmission pipeline 2, automatic air regulating valve 3, sieving chamber 5, ultra-thin sample stage 6 (in order to reduce the flow field disturbance in the experimental test, the thickness of the ultra-thin sample stage 6 is generally selected as the sieve One thousandth of the height of the sub-chamber 5), the discharge pipeline 8, the powder material collection box 9, the main control system 11 and the sample table vibrator 13;

[0042] One end face of the screening chamber 5 is provided with a jet port 4, and the jet port 4 is communicated with the high-pressure gas source 1 through the gas transmission pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com