Heat insulation strip high-temperature bending device and using method

A technology of bending device and heat insulation strip, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low processing efficiency, broken heat insulation strip, poor plastic processing flexibility, etc. Maintenance costs, preventing damage to the insulation strip structure, and saving the area occupied by the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the construction of the technical means, creation features, achievement goals and effects realized by the present invention, the present invention will be further described below with reference to the specific embodiments.

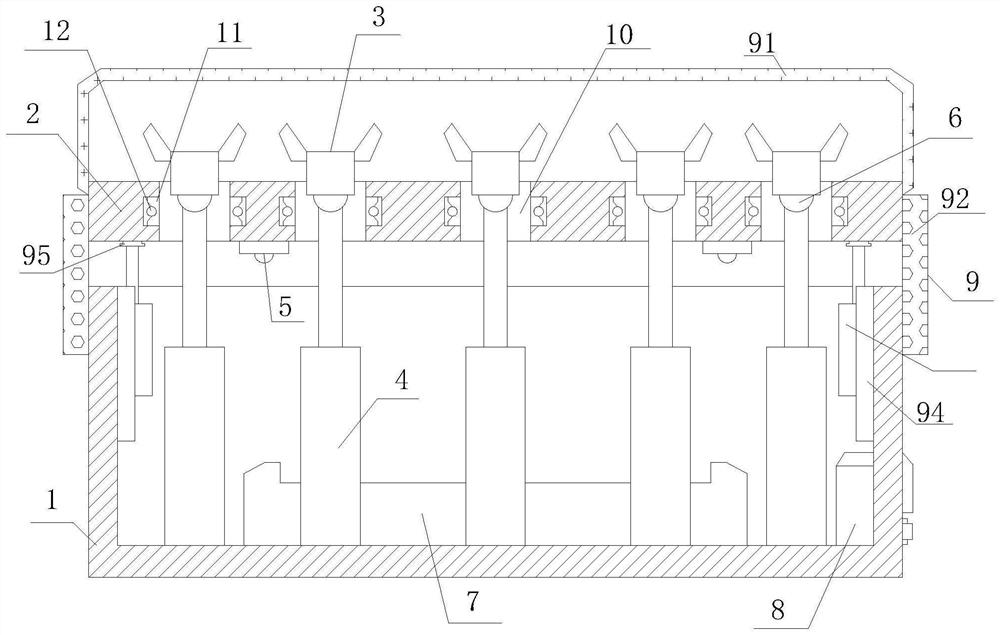

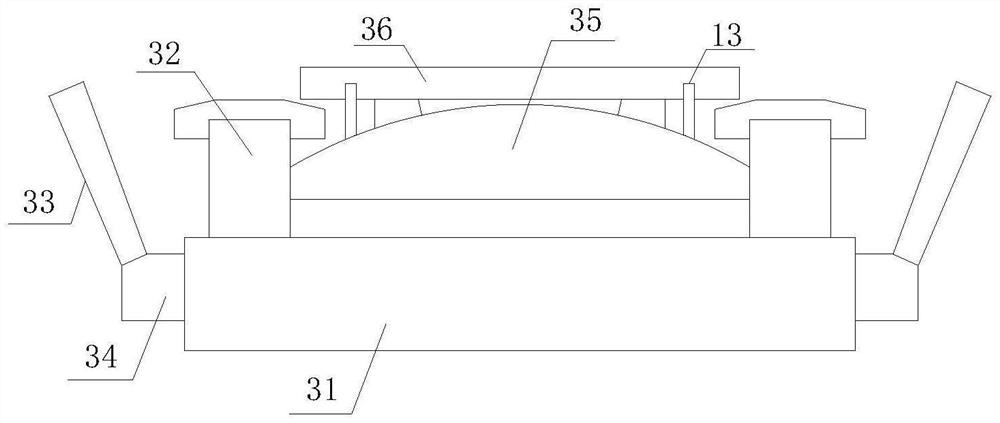

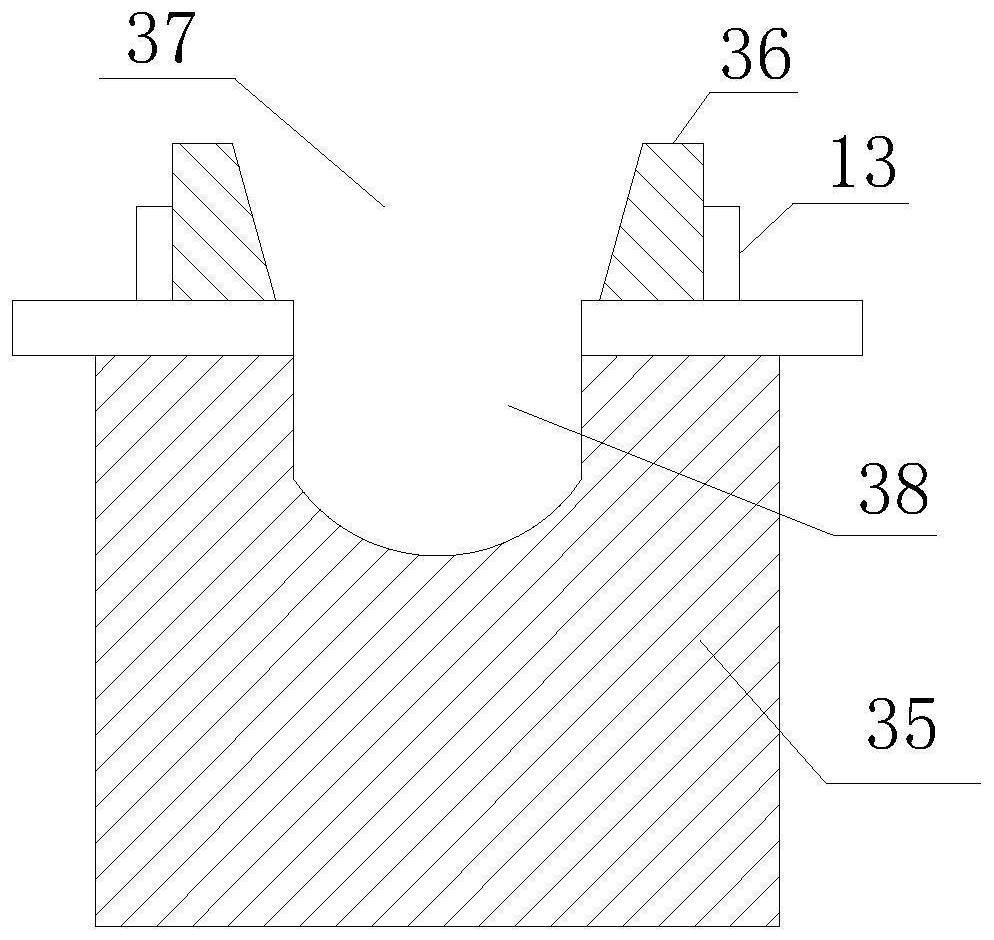

[0026] see figure 1, a high-temperature bending device for heat insulation strips, comprising a bearing base 1, a workbench 2, a positioning plastic block 3, a lifting drive mechanism 4, a temperature sensor 5, a heating mechanism 7 and a drive circuit 8, the upper end surface of which passes through the adjustment mechanism 9 It is hinged with the lower end surface of the workbench 2, and the upper end surface of the workbench 2 is at an angle of 0°-90° with the horizontal plane. The workbench 2 is a plate-like structure with a rectangular cross-section. , and each adjusting groove 10 is provided with a number of positioning plastic blocks 3 that are evenly distributed along the axis of the adjusting groove 10, each positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com