System for tracking welding seam deviation through two-dimensional coaxial compensation galvanometer and deviation correction method

A coaxial and offset technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high R&D cost, complex welding head structure, and unsatisfactory welding effect, so as to avoid space and reduce R&D. Cost, solve the effect of unsatisfactory welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

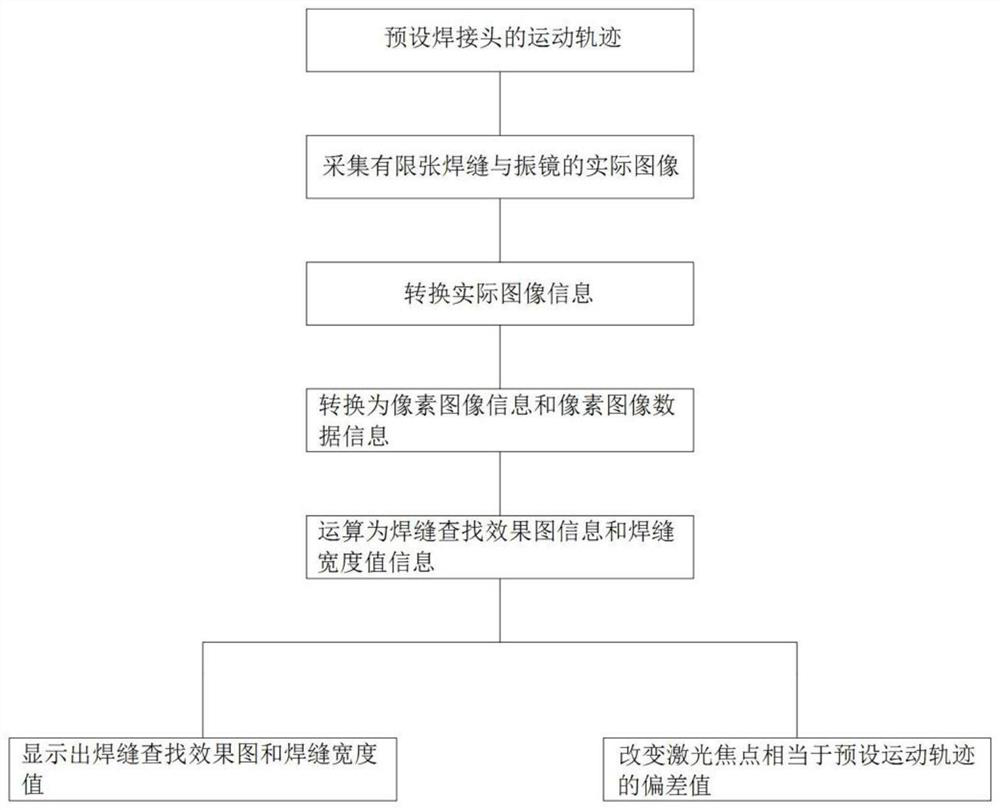

[0028] The purpose of the present invention is to adjust the deviation of the galvanometer relative to the preset motion track through the offset system to ensure that the laser focus is always on the welding seam, thereby realizing the deviation correction of the galvanometer tracking the welding seam.

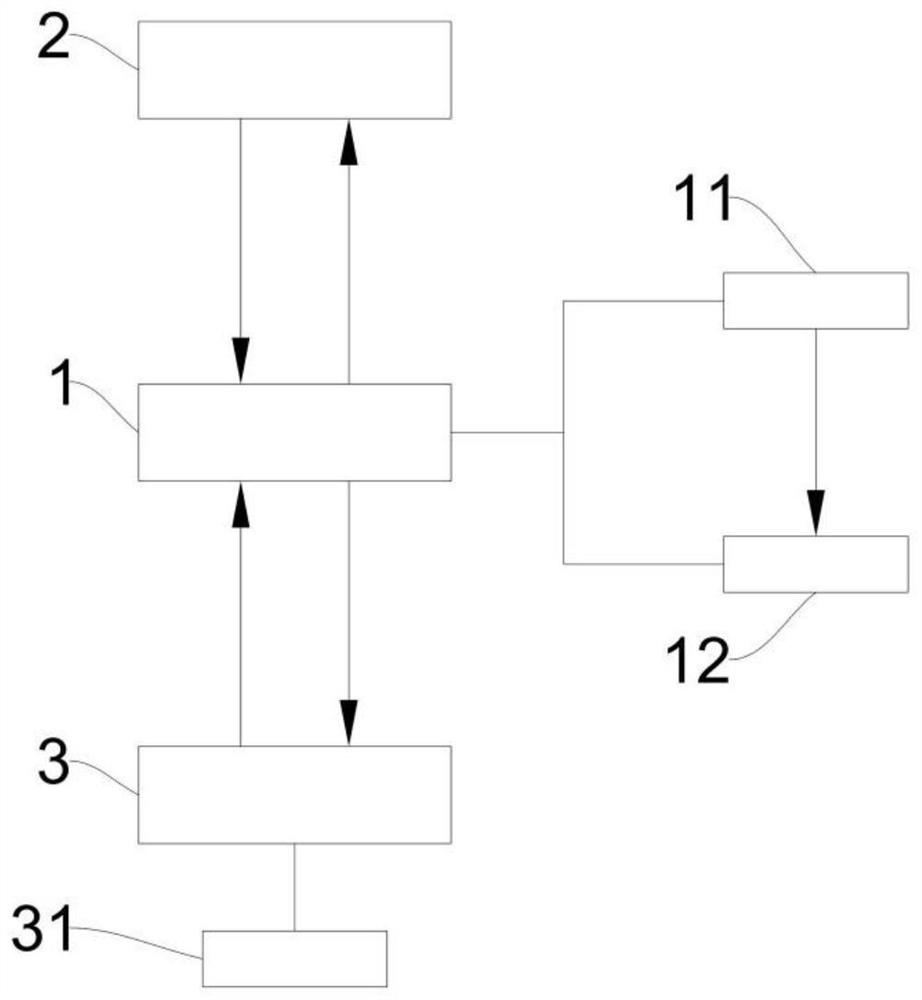

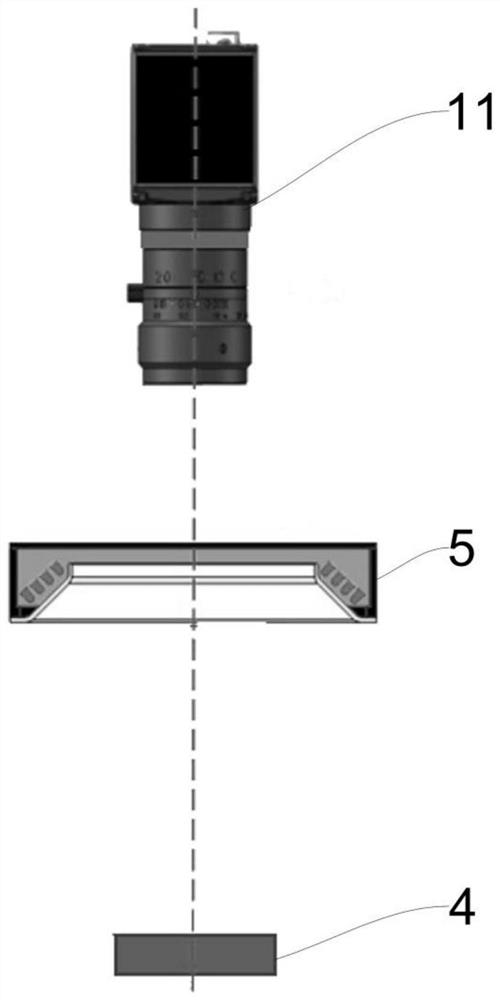

[0029] see figure 1 As shown, in this embodiment, the offset system includes an information processing module 1, a human-computer interaction module 2 and a main control scheduling module 3, and the information processing module 1 is used to run the actual image information into actual image information and pixels. The image data information, and then the pixel image data information is calculated into the offset value information between the galvanometer and the welding seam through the information processing module 1 . Then, through the information processing module 1, the feature information of the welding seam is proposed to calculate the welding seam width information an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com