A TBM-based microseismic monitoring line automatic laying device and application method

A technology of automatic laying and microseismic monitoring, applied in cable laying equipment and other directions, can solve the problems of increasing the difficulty of recovering cables, unfavorable pedestrians passing through, narrow passages, etc., achieving the effect of simple structure, reduced labor intensity, and avoidance of mobile equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

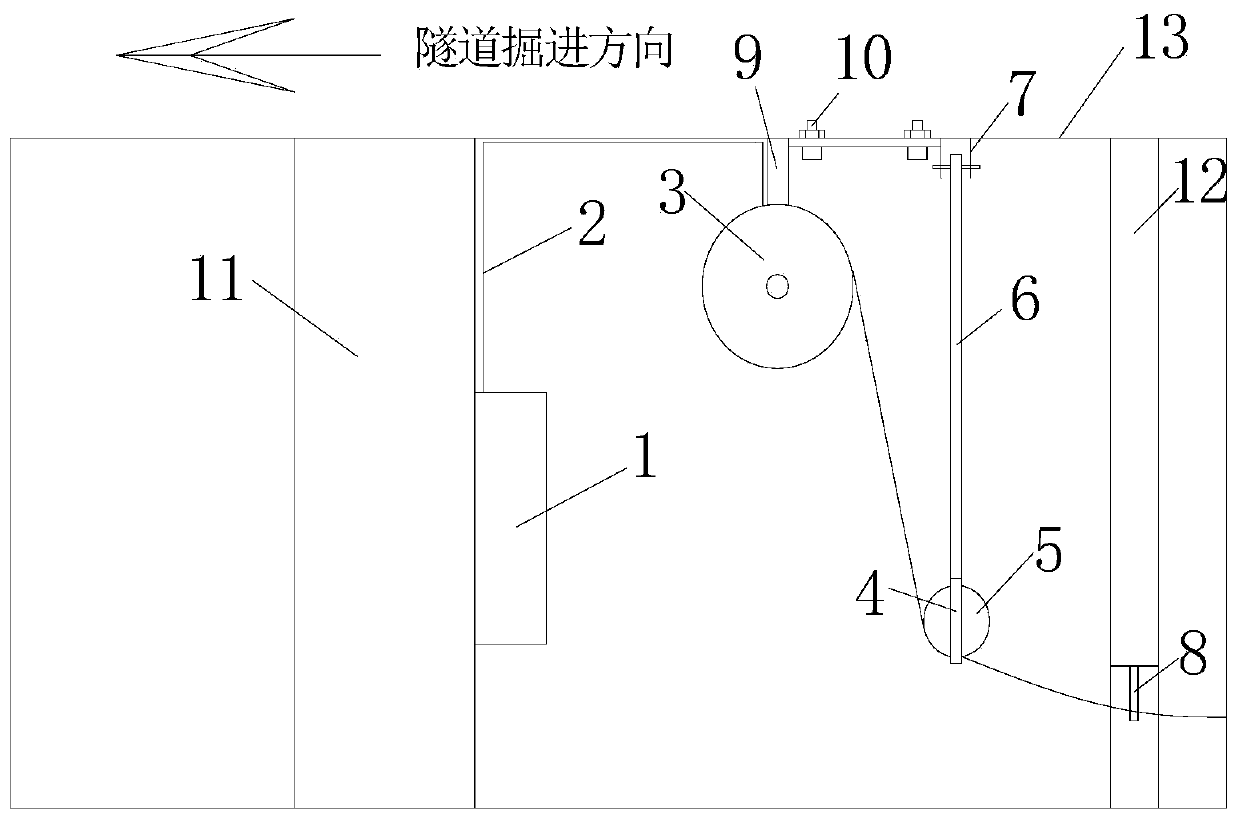

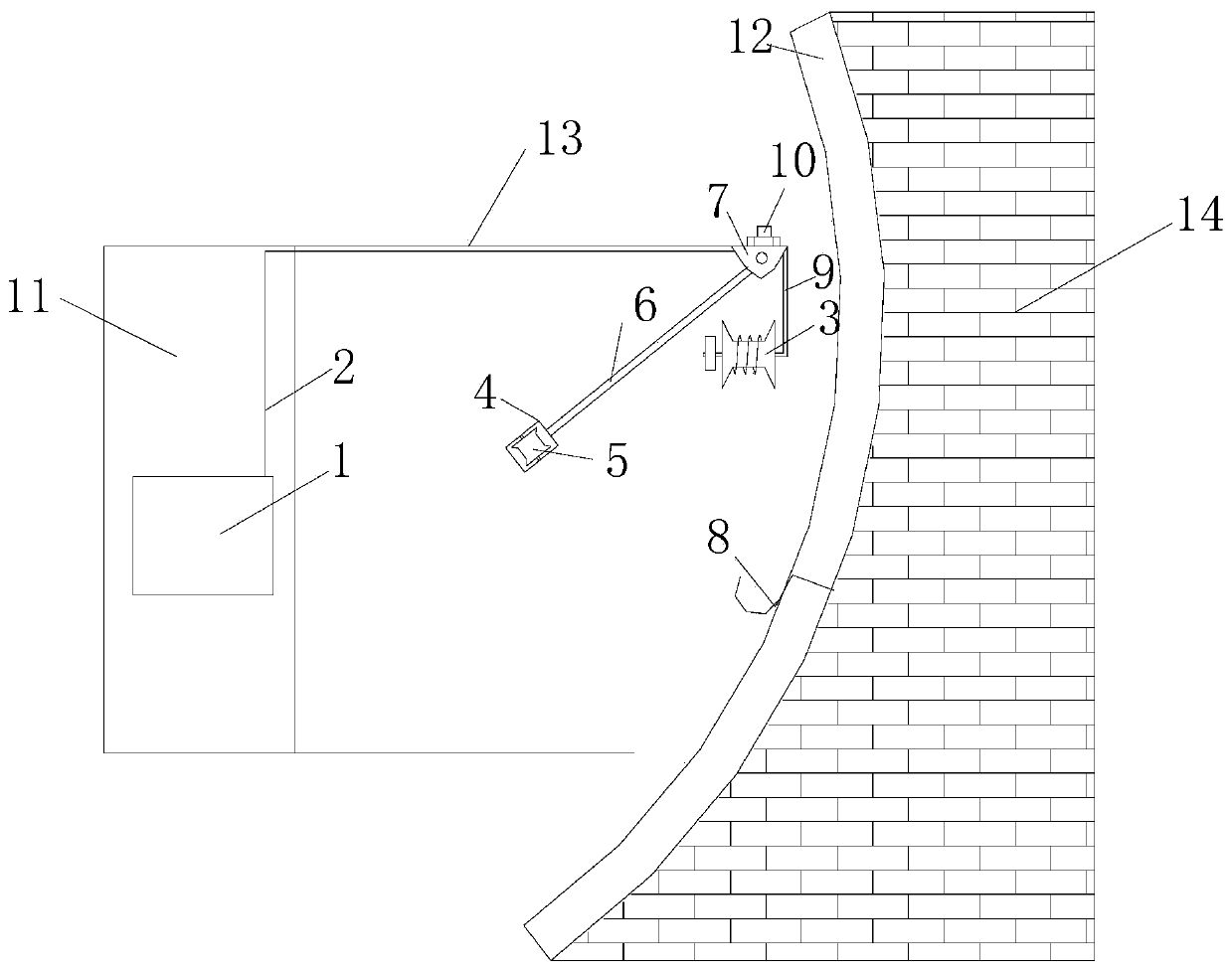

[0032] combined with figure 1 and figure 2 The present invention is described in detail:

[0033] The above-mentioned automatic laying device for microseismic monitoring line based on TBM is characterized in that it includes six groups of units, and each group of units includes a connecting member 10, a winding wheel 3, a laying wheel 5, a laying pole 6, and a fixed wheel frame 4.

[0034] The connecting member 10 includes the connecting ear 7 and the hanging ear 9, and the connecting member 10 can be fixed on the first layer of the top plate 13 of the TBM through bolt connection;

[0035] The above-mentioned reel 3 is fixed on the connecting member 10 through the suspension ear 9;

[0036] The above-mentioned wire laying rod 6 is fixed on the connecting member 10 through the connecting ear 7;

[0037] The above-mentioned fixed wheel frame 4 is fixed on the tail end of the laying rod 6 through threaded connection;

[0038] Above-mentioned laying wheel 5 is placed in descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com