Light plastic well lid processing and forming device and forming method

A technology for processing and forming manhole covers, which is applied in the field of light plastic manhole cover processing and forming devices, can solve problems such as production safety hazards, hydraulic press injuries, and hydraulic press dangers, and achieve the effects of improving production safety, saving power resources, and reducing production costs

Active Publication Date: 2022-05-31

JIANGSU RUIYUAN PLASTIC CO LTD

View PDF19 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the deficiencies of the prior art, the present invention provides a light plastic manhole cover processing molding device and molding method, which solves the problem that the hydraulic press is relatively dangerous during the pressing process. After working for a long time, the operator may be crushed by the hydraulic machine due to misoperation, which will bring safety hazards to the production work.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

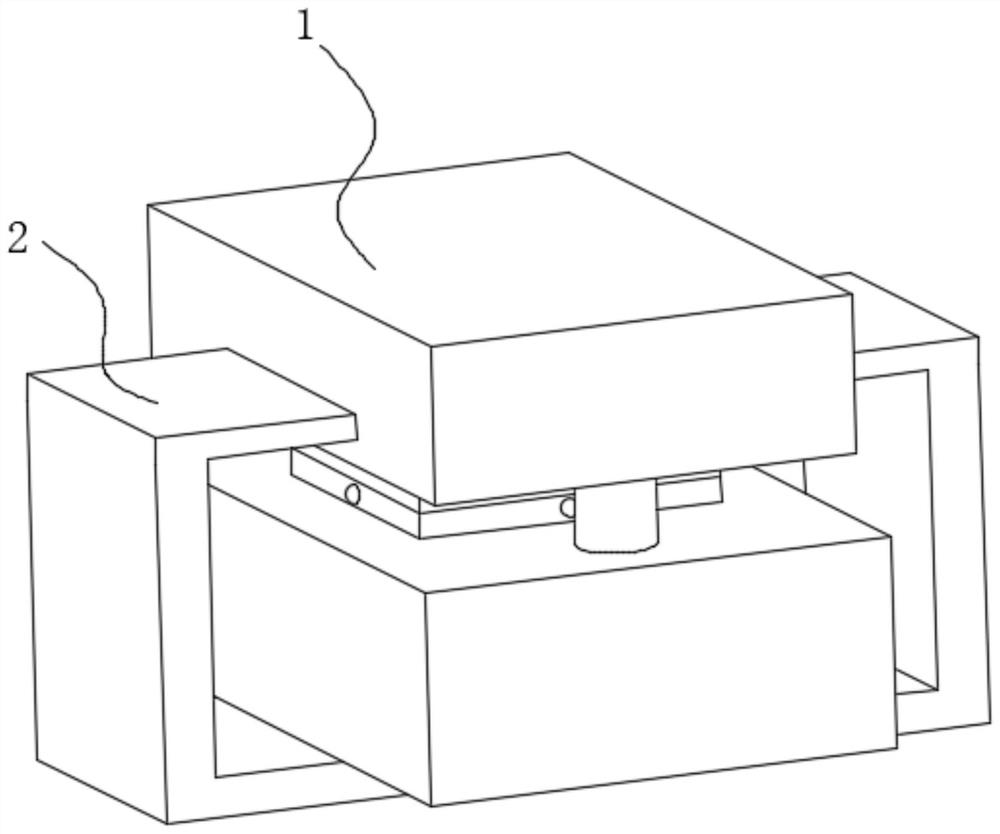

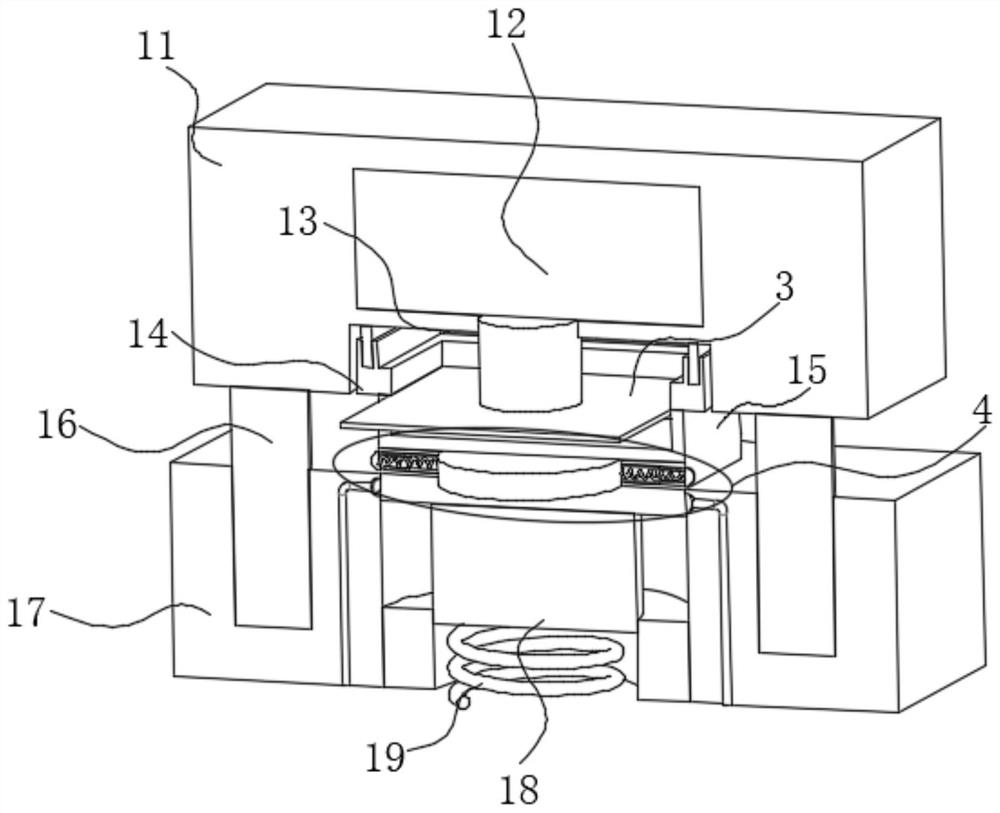

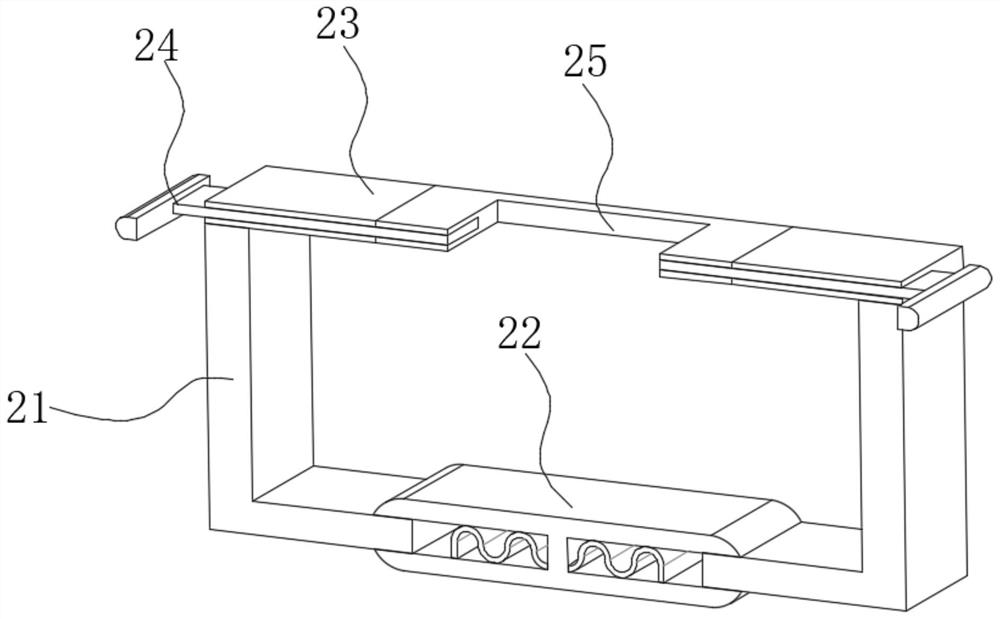

Login to View More Abstract

The invention belongs to the technical field of well lid machining, and particularly relates to a light plastic well lid machining forming device and method.The light plastic well lid machining forming device comprises an extrusion device, a sliding inserting opening is formed in the upper portion of an inner cavity of the extrusion device, and well lid feeding devices are symmetrically arranged on the upper portion of the inner cavity of the extrusion device through penetrating inserting openings; the extrusion device comprises an upper fixing box shell, a hydraulic power device is fixedly connected to the middle of an inner cavity of the upper fixing box shell, and a penetrating inserting opening is formed in the lower portion of the inner cavity of the upper fixing box shell. Compared with a common hydraulic machine, the device is characterized in that feeding does not need to be directly carried out in interlayers on the upper side and the lower side of the hydraulic machine, in the well lid pressing process, the device almost does not have too large action when observed from the outside, the device does not need to be opened to carry out material taking work in the material taking process, and the material taking efficiency is greatly improved. And the safety that operators are prevented from being accidentally injured by the hydraulic machine is reflected from each link of pressing, so that the safety and scientificity of production are effectively improved.

Description

A light-weight plastic manhole cover processing and forming device and forming method technical field The invention belongs to the technical field of manhole cover processing, specifically a kind of light-weight plastic manhole cover processing and forming device and components. type method. Background technique With the development of society, more and more cities gradually use plastic composite manhole covers, and this manhole cover adopts unsaturated poly Ester resin-based fiber-reinforced thermosetting composites, also known as bulk molding compounds, are made by compression molding technology. A new type of environmentally friendly cover. The composite manhole cover adopts the high temperature and high pressure one-step molding technology, which has high polymerization degree, high density and good quality. Good impact resistance and tensile strength, with the advantages of wear resistance, corrosion resistance, no rust, no pollution, maintenance-free, etc., an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C70/46B29C70/54B29C43/02B29C43/34

CPCB29C70/46B29C70/54B29C43/02B29C43/34

Inventor 颜瑞环胡明

Owner JIANGSU RUIYUAN PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com