Threading device of firework machine

A threading device and fireworks technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of high production cost, increased production time, low production efficiency, etc., and achieve the effect of saving generation time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below through specific embodiments.

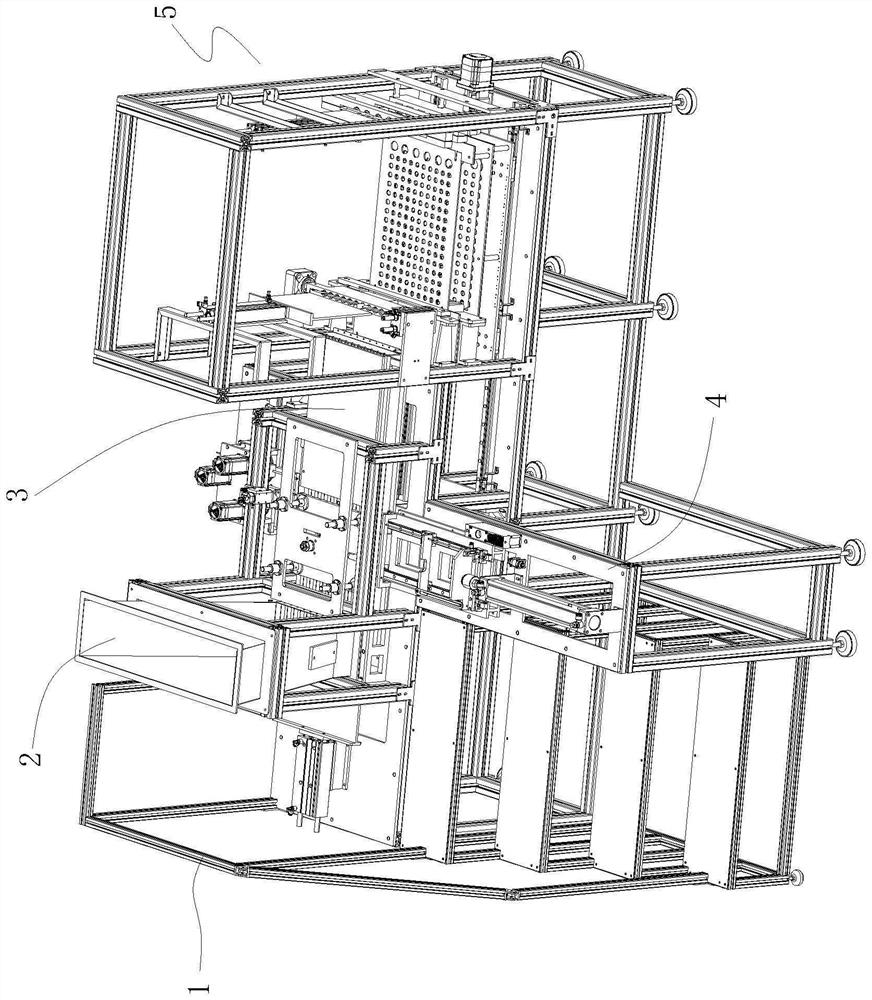

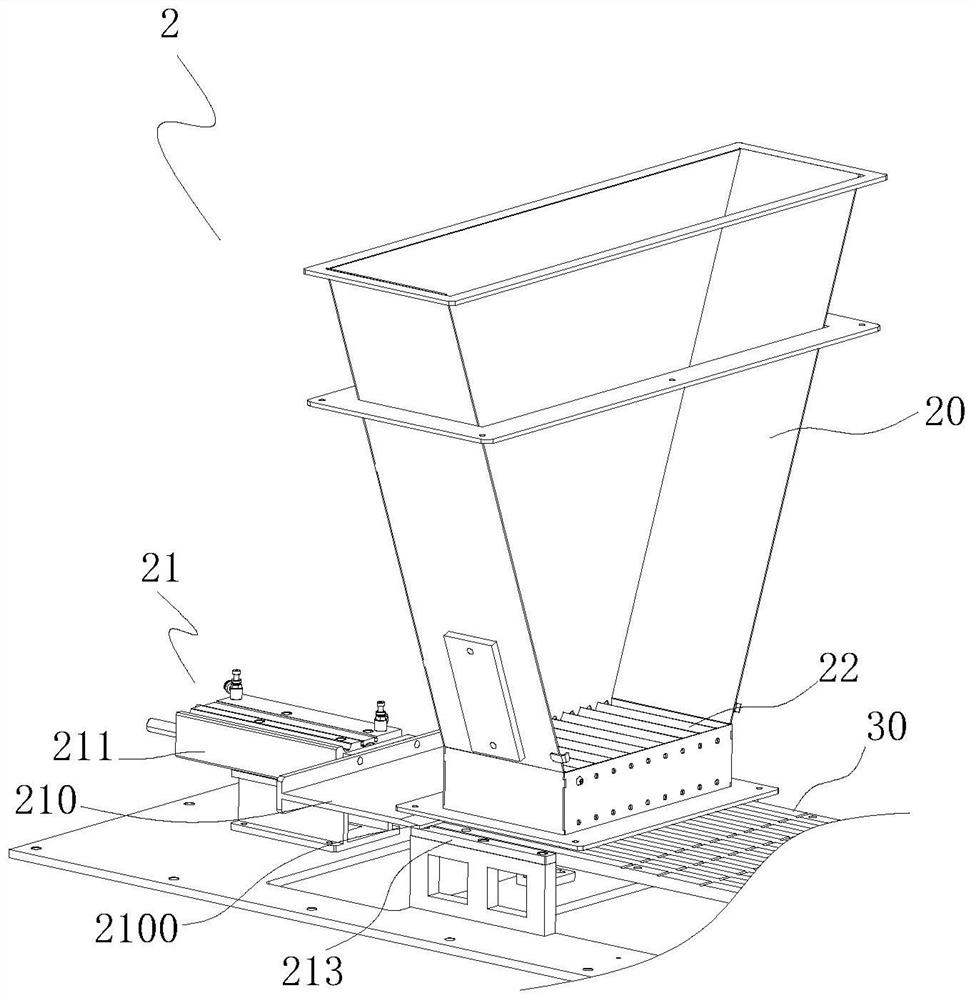

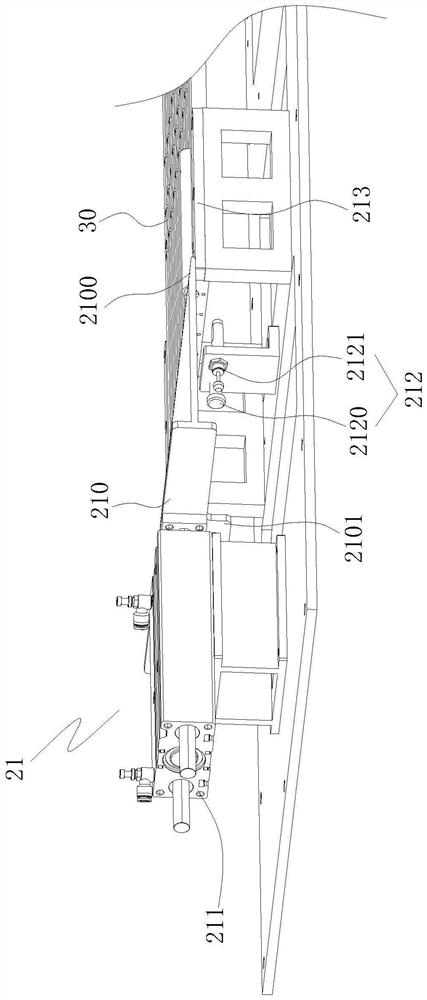

[0045] refer to Figure 1 to Figure 15 , a firework machine for automatically arranging and assembling fireworks tubes of the present invention, comprising a frame 1, a feeding device 2, a conveying device 3, a threading device 4 and an orientation arrangement 5, a feeding device 2, a conveying device 3, and a threading device 4 And alignment arrangement device 5 is arranged on frame 1. The feeding device 2 is used to transport the fireworks tubes to the conveying device 3, and the conveying device 3 includes a conveying plate 30 and a pressing plate 31, and the conveying plate 30 is used to accept the fireworks tubes transported by the feeding device 2 and make the fireworks The cylinders are arranged in parallel at intervals and conveyed along the conveying direction. The conveying plate 30 is divided into a material receiving end, a punching position, a threading position and a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com