Improved dental implant fatigue test fixture

A technology for dental implants and fatigue testing, which is applied to the application of repetitive force/pulse force to test the strength of materials, measuring devices, instruments, etc., and can solve the problems of affecting the test results, inaccurate test results, and redundant dental implant samples. , to achieve the effect of offsetting the interference of horizontal external force and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

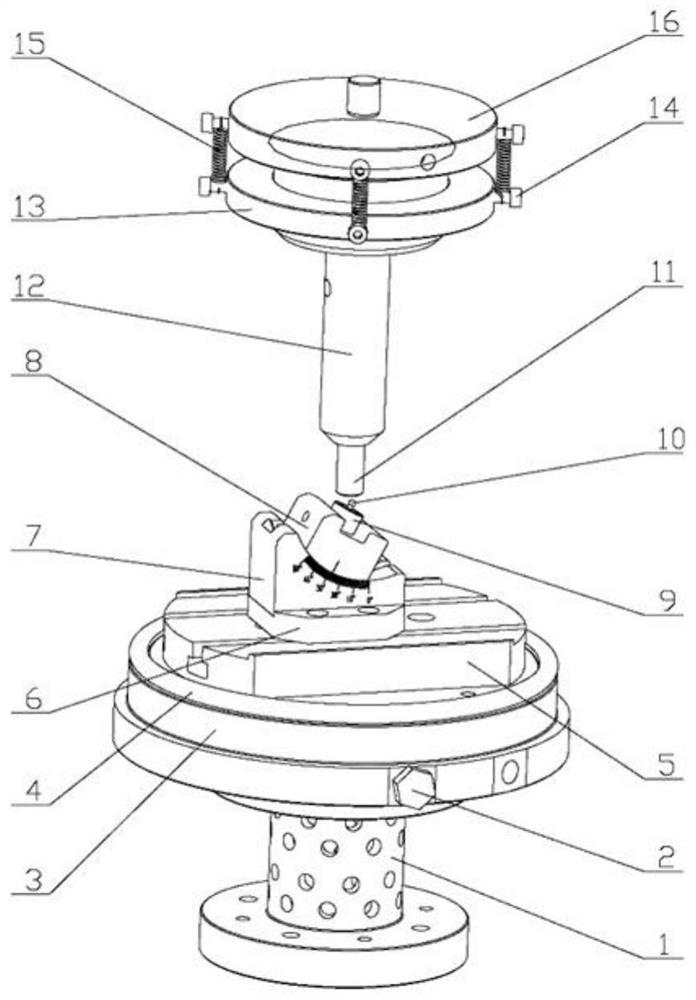

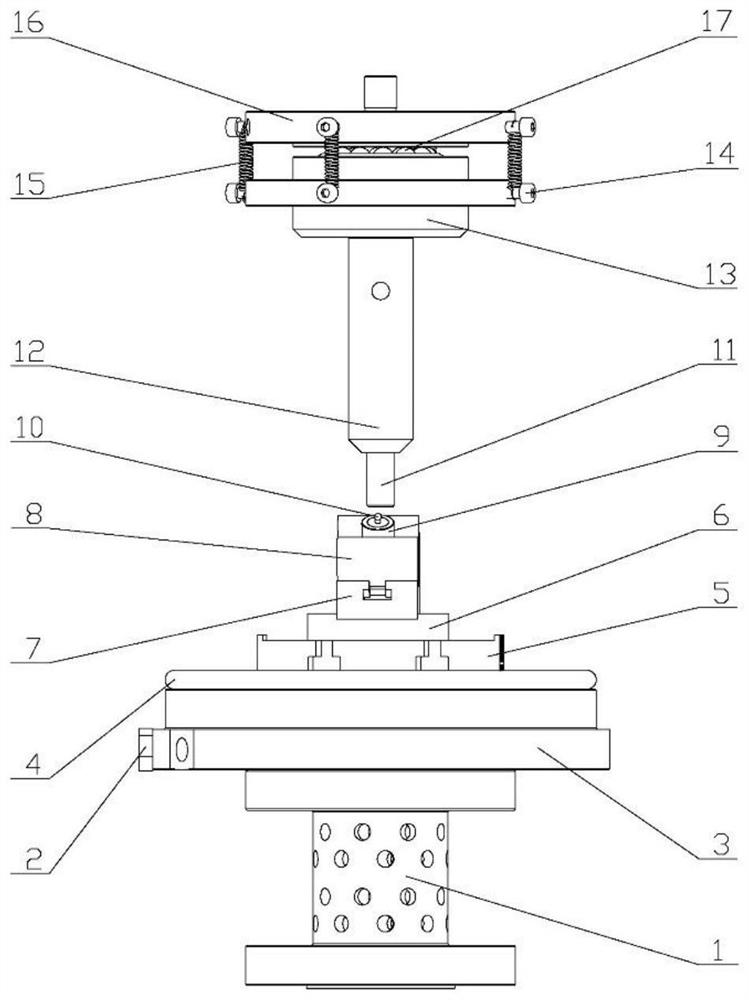

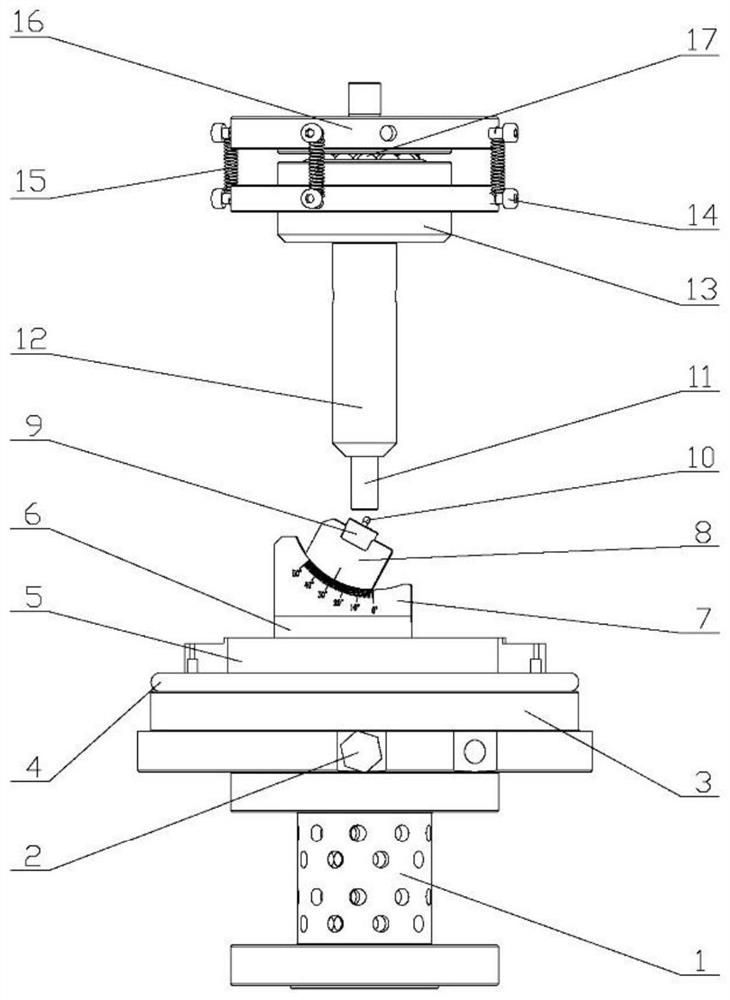

[0029] like Figure 1 to Figure 3 As shown, this embodiment provides an improved dental implant fatigue test fixture, which is mainly composed of a compression system, a fixing system and a water bath system.

[0030] like Figure 4 As shown, the compression system mainly includes an upper pressure head 11, a connecting rod 12, a sliding pressure plate 13, a compression plate 16, a thrust ball bearing core 17 and a replaceable pressure plate 18, an upper pressure head 11, a connecting rod 12, and a sliding pressure plate 13 , Compression plate 16, thrust ball bearing core 17 and replaceable pressure plate 18 are arranged coaxially.

[0031] The main body of the upper indenter 11 is a rod-shaped cylindrical structure, the lower end of which is used to exert force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com