Oil-cooled motor rotor

A motor rotor and rotor technology, applied in the direction of motors, electric components, electric vehicles, etc., can solve the problems of overheating and demagnetization of magnetic steel, affecting the performance, reliability and life of the motor, and the inability to cool the iron core and windings, etc., to achieve a balanced temperature distribution , Improve continuous working power and improve system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

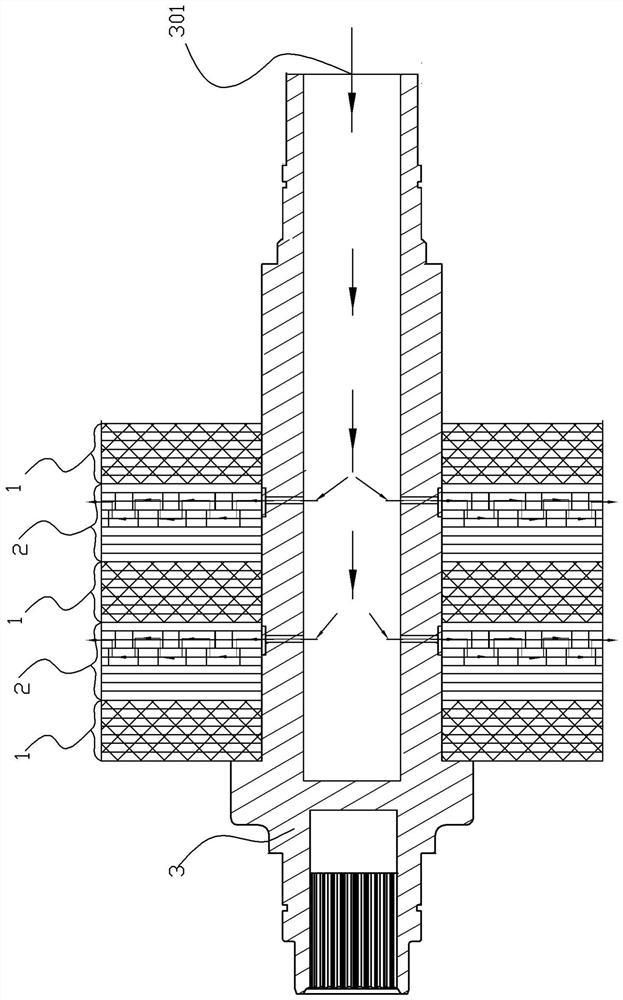

[0041] An oil-cooled motor rotor, for specific embodiments see Figure 1-Figure 8 , which consists of a rotor core assembly 1, a rotor integrated oil circuit core assembly 2, and an oil-cooled motor shaft 3;

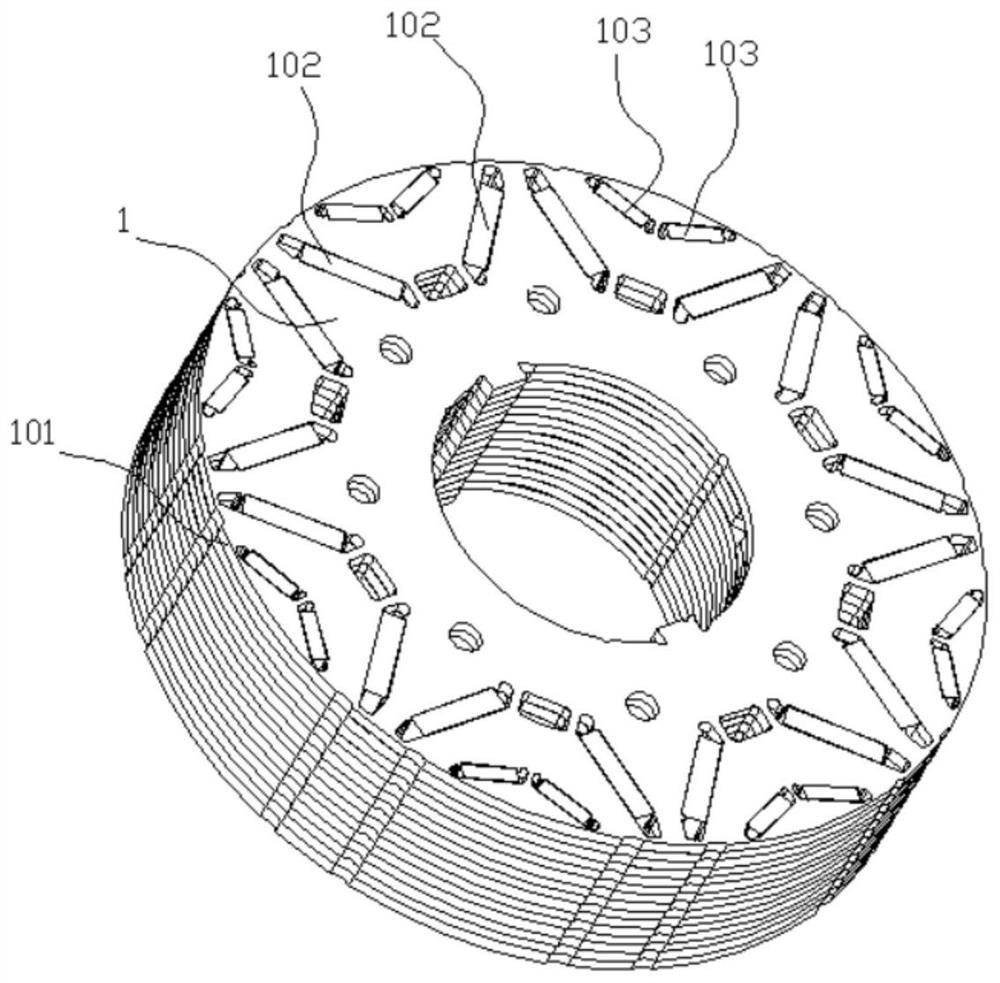

[0042] The rotor core assembly 1 is made of laminated rotor punches 101, and is equipped with magnetic steel 102 and magnetic steel 103. There are protruding keys in the inner hole of the rotor iron core assembly, and the key through the inner hole of the rotor iron core can be cooled with oil. The keyway 304 on the motor shaft 3 fits closely;

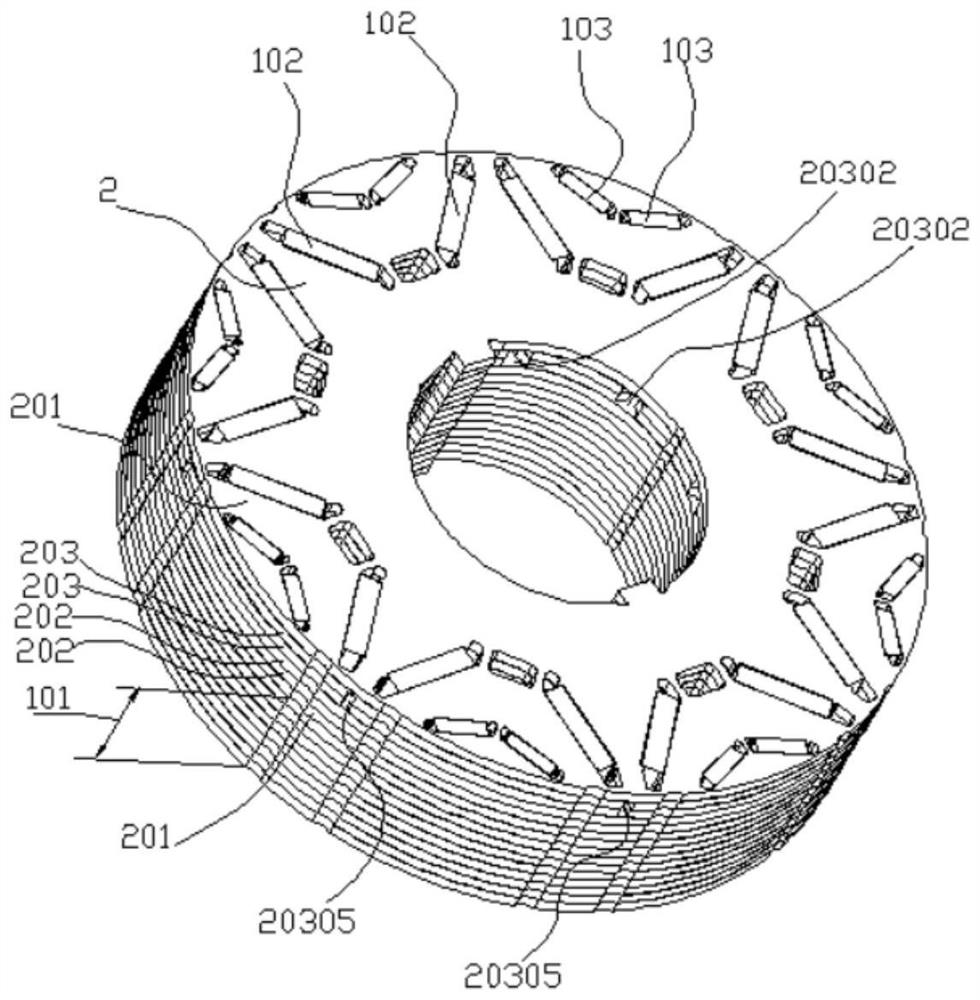

[0043] The rotor integrated oil circuit core assembly 2 forms an oil channel in the rotor integrated oil circuit core through the combination of rotor punches of different structures. In specific implementation, the rotor integrated oil circuit iron core assembly 2 is formed by stacking the rotor punching plate 101, the rotor oil isolation punching plate 201, the rotor oil guiding punching plate 202, and the rotor oil injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com