Flexible connection structure of upper cover plate and lower cover plate of vapor chamber

A technology of flexible connection and temperature equalization plate, which is applied in the structural parts of electrical equipment, cooling/ventilation/heating transformation, and modification by conduction heat transfer, etc. Good flexibility and foldability, meet support requirements, and ensure the effect of normal heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

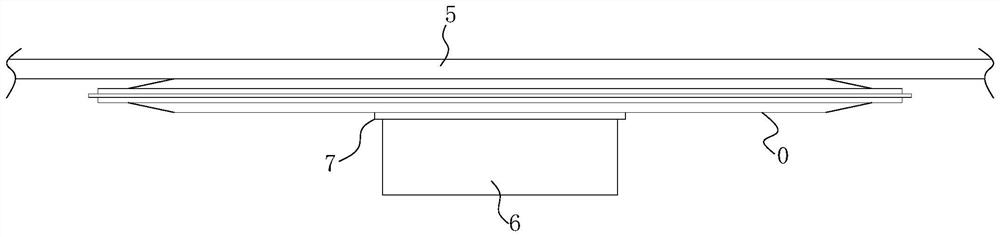

[0030] Such as Figure 1-11 The vapor chamber shown above is mainly used in mobile phones, tablet computers, notebook computers and other devices with flexible and foldable screens, and is used to dissipate heat and cool down core electronic devices with high heat generation density, and is especially suitable for flexible screens to use. The present invention includes a vapor chamber body 0 , the body 0 is respectively in contact with a heat source 6 and a flexible heat dissipation backplane 5 , and guides heat generated by the heat source 6 from the flexible heat dissipation backplane 5 .

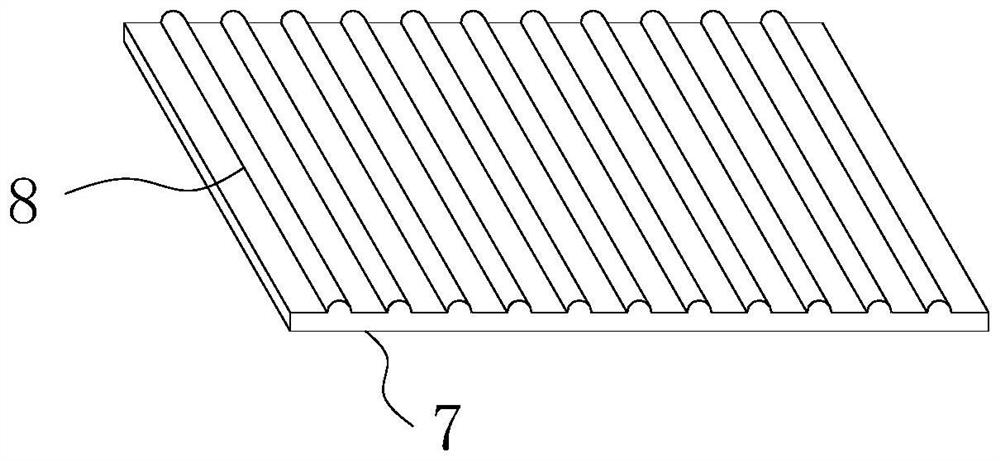

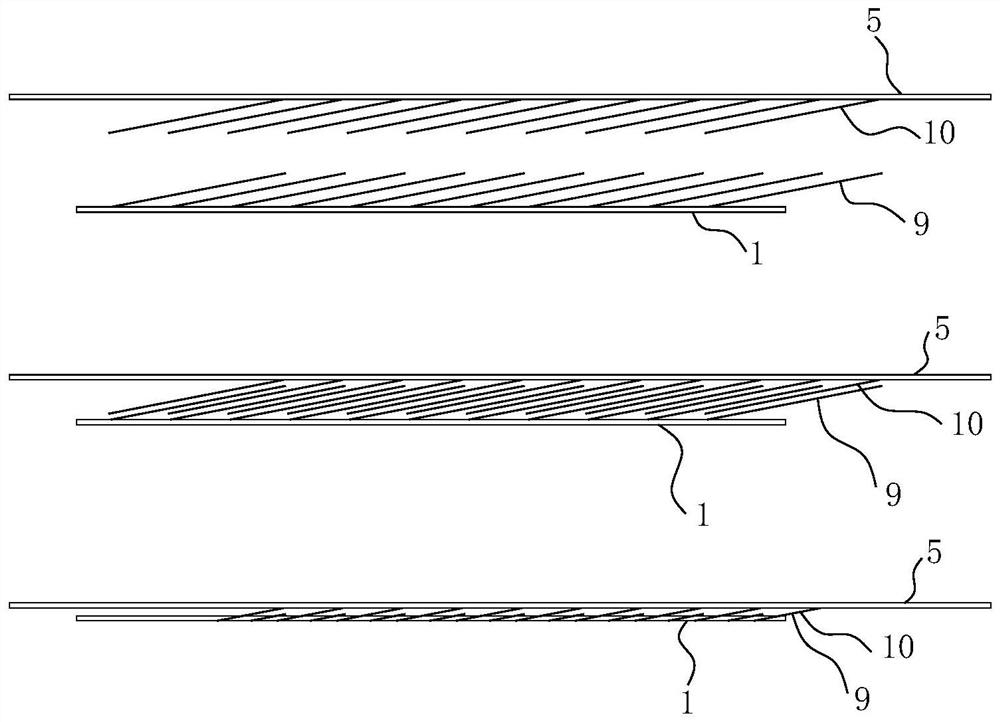

[0031] Compared with the traditional vapor chamber body 0, the present invention is the same in that the body 0 includes a flexible upper cover 1 and a flexible lower cover 2 whose edges are connected to each other, and the flexible upper cover 1 and the flexible lower The cover plates 2 are supported by a supporting mechanism, and a working chamber is formed between them. The inner sur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap