Multi-pressure-head flexible composite leveling mechanism for thin plate and method for leveling memory thin plate

A thin plate and pressure head technology, applied in the field of multi-pressure head flexible composite leveling mechanism and using it to level memory thin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The solution of the present invention will be explained below in conjunction with the embodiments. Those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be construed as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, the technique or condition described in the literature in the field or the product specification is used. The reagents or instruments used without the manufacturer's indication are conventional products that can be obtained from the market.

[0018] The present invention will be described below with reference to specific embodiments. It should be noted that these embodiments are merely illustrative and do not limit the present invention in any way.

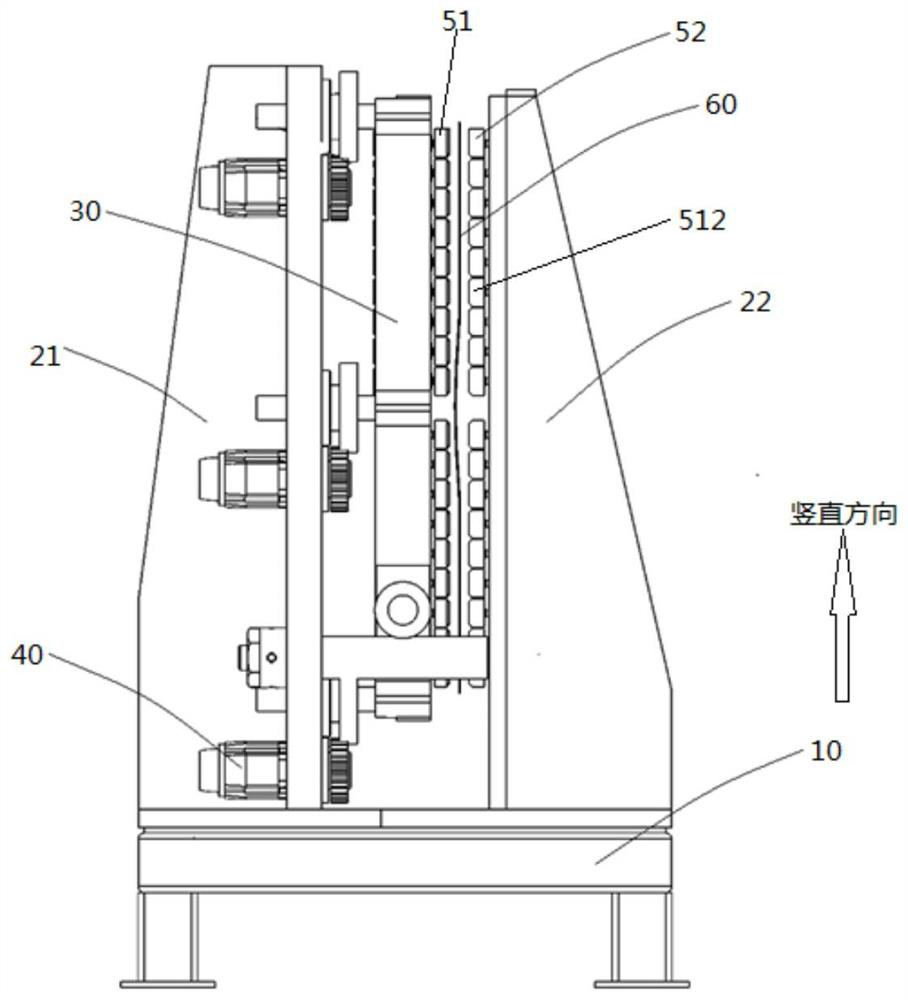

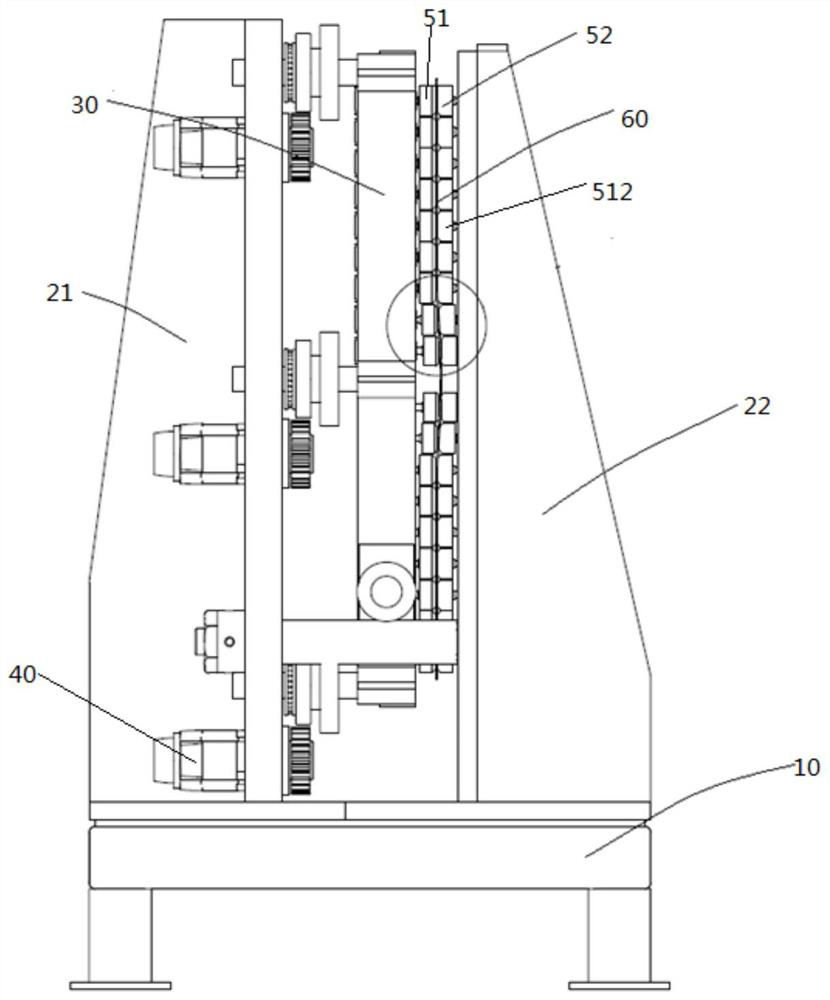

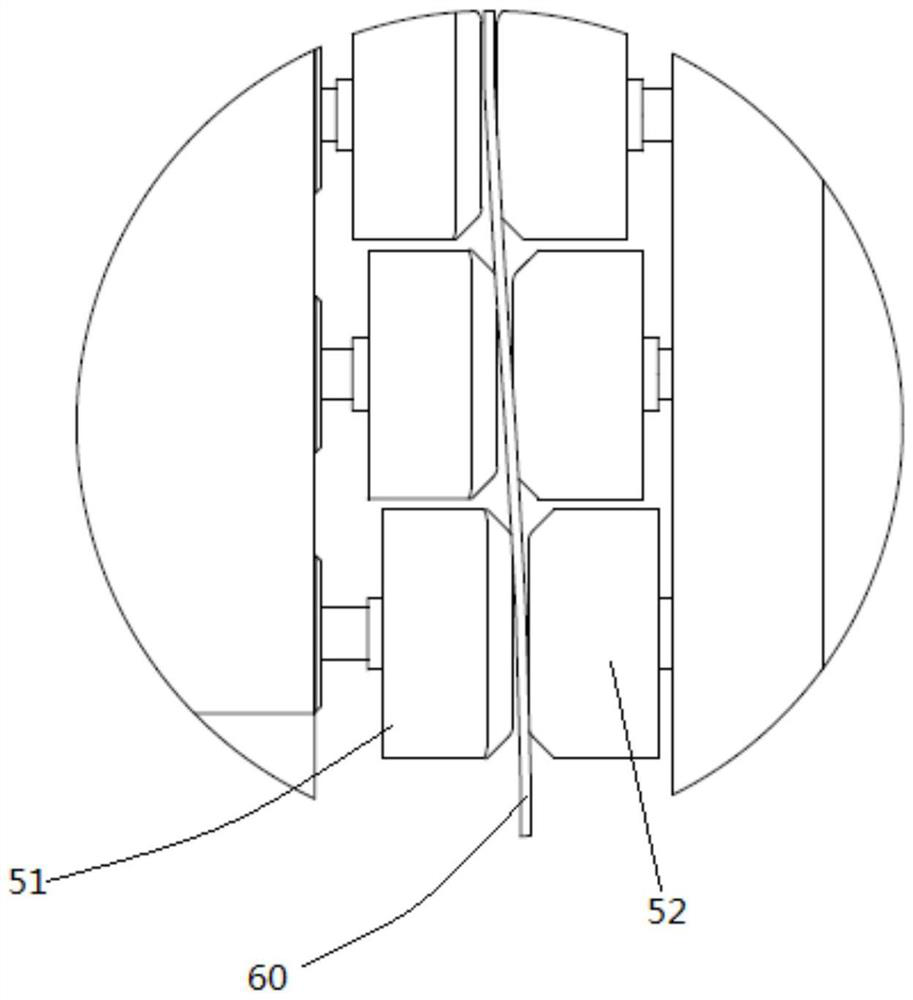

[0019] In one aspect of the present invention, the present invention provides a multi-head flexible composite leveling mechanism for thin plates. According to an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com