Leveling mechanism based on gluing machine

A leveling mechanism and bonding machine technology, applied in the field of fabric processing, can solve problems such as weak softness, limited product quality, deformation, etc., achieve rapid expansion and improve the leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

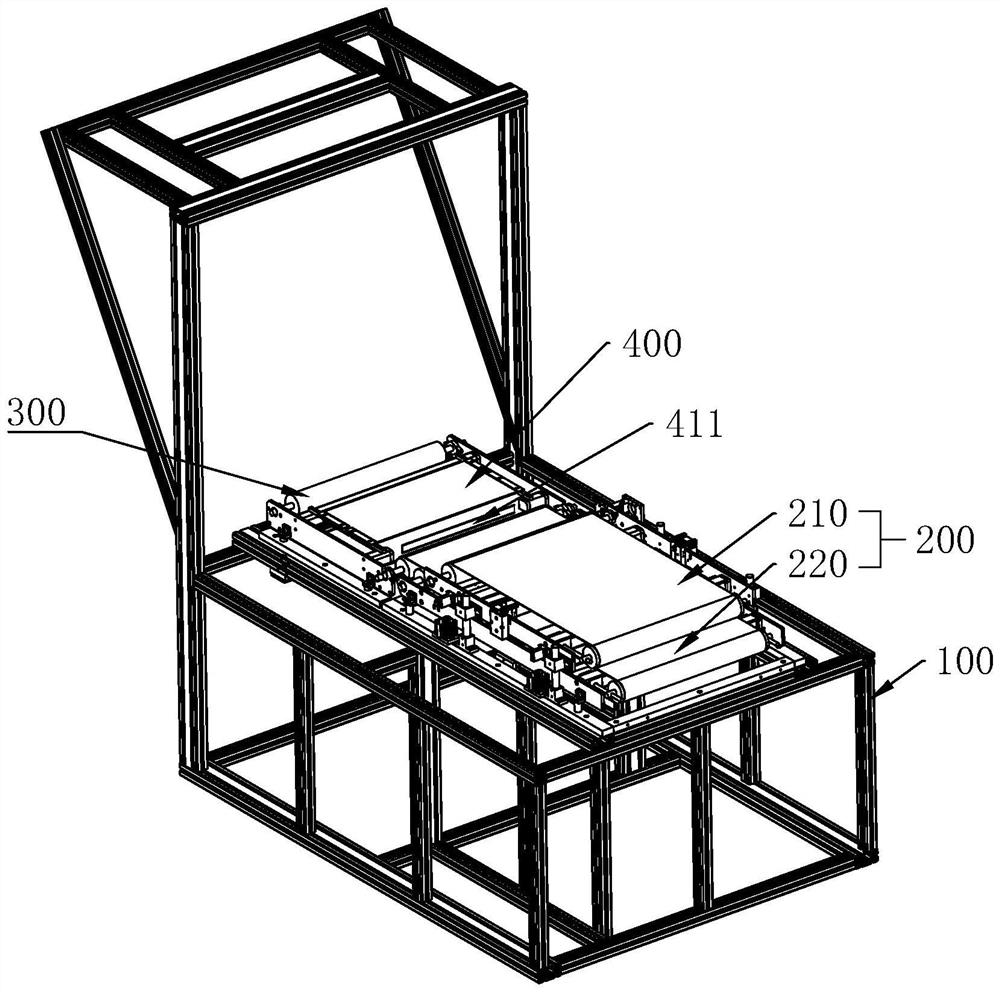

[0044] the rack 100;

[0045] The conveying assembly 200 is arranged on the frame 100, and is divided into an upper conveyor belt 210 and a lower conveyor belt arranged up and down

[0046] A heating assembly is provided on the frame 100 for transferring the generated heat to the upper conveyor belt 210 and the lower conveyor belt

[0047] and the pressing assembly 300, which is arranged on the frame 100 and is located at the rear side of the conveying assembly 200, is used for heating the heated

[0048] Wherein, between the conveying assembly 200 and the pressing assembly 300 is also provided with a leveling mechanism 400 for heating the cloth

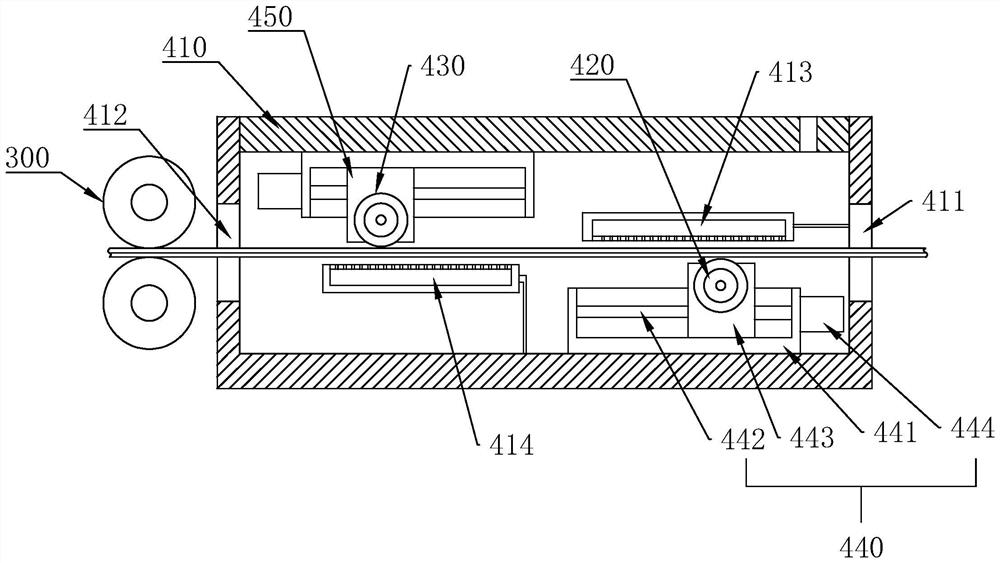

[0051] As shown in FIG. 2, in this embodiment, specifically, the leveling mechanism 400 includes:

[0052] The leveling box 410 has an installation chamber inside, and its left and right sides are respectively provided with an inlet that communicates with the installation chamber

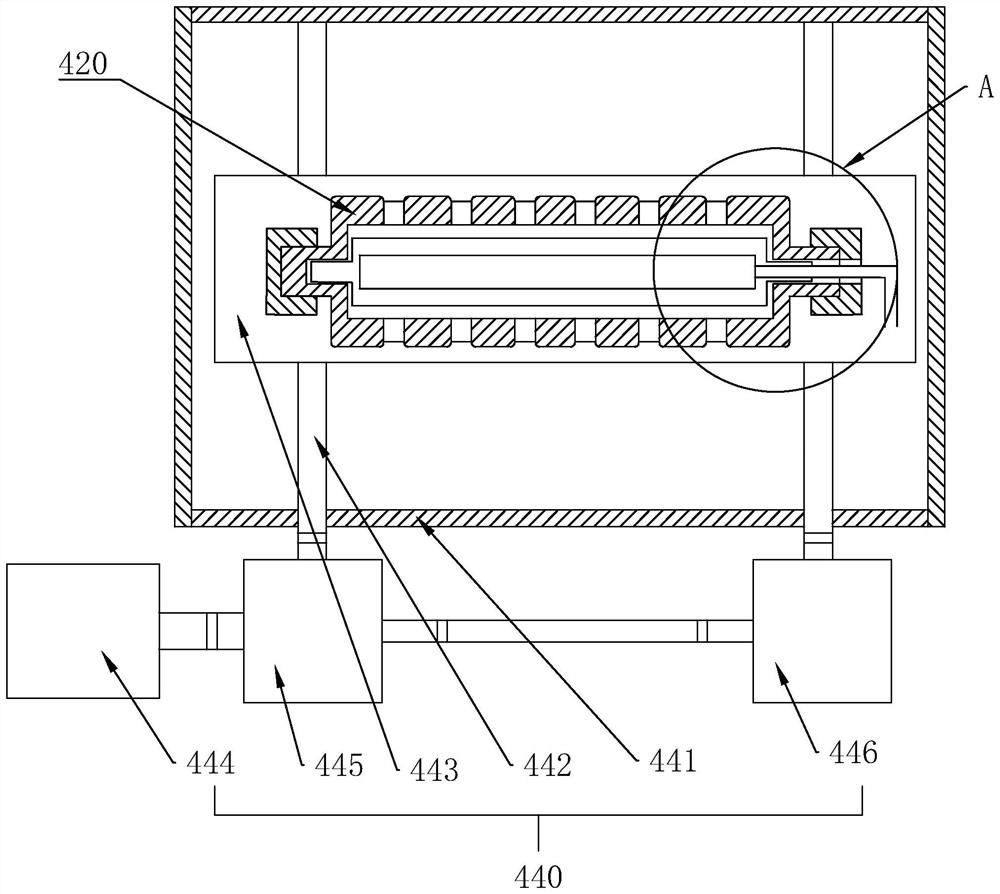

[0053] The first leveling roller 420 is slidably arranged...

Embodiment 2

[0069] As shown in Figure 3, Figure 4, Figure 5 and Figure 6, in this embodiment, the structure of the first leveling roller 420 and the second leveling roller 430

Embodiment 3

[0074] As shown in FIG. 2, FIG. 5 and FIG. 6, in this embodiment, the first plate body 413 and the second plate body 414 both have a second gas

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com