Supporting nodes of large-span V-shaped truss structure system

A truss structure, long-span technology, applied in the direction of building structure, building type, building, etc., can solve the problems of easy fracture at the connection between the support pipe and the main strut, complex space structure of the support pipe, complicated angle of the support pipe, etc. Achieve the effect of easy maintenance and replacement, reduced weight, and easy support nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

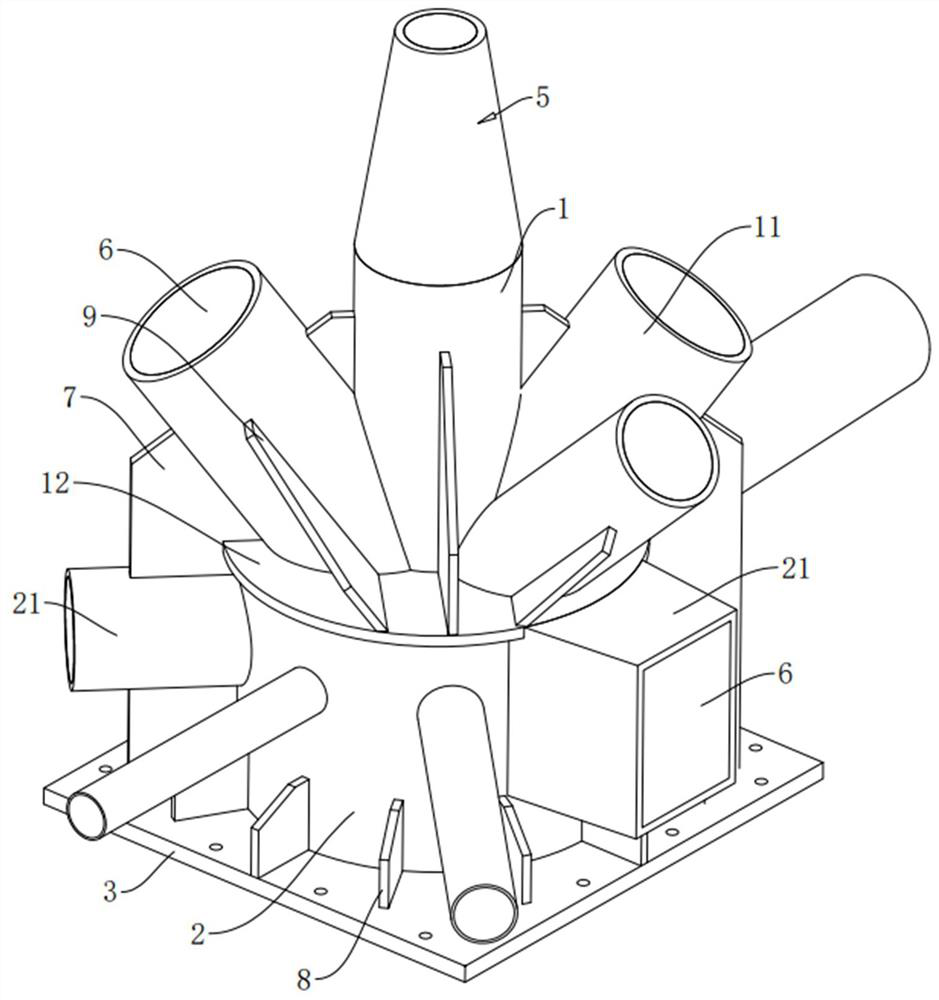

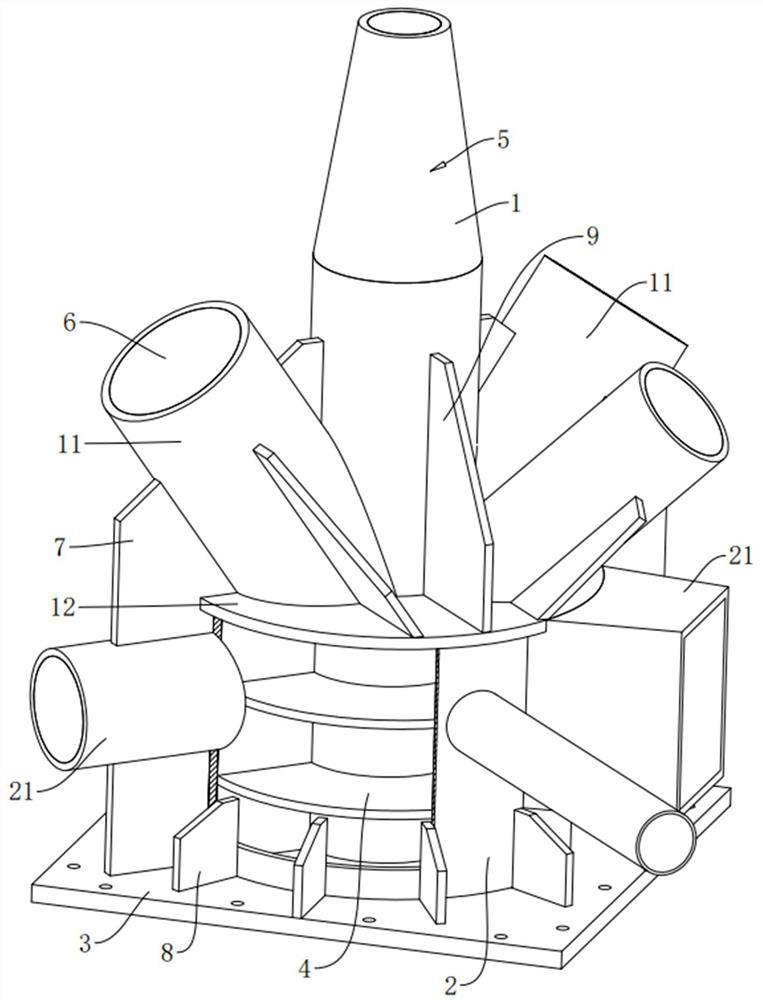

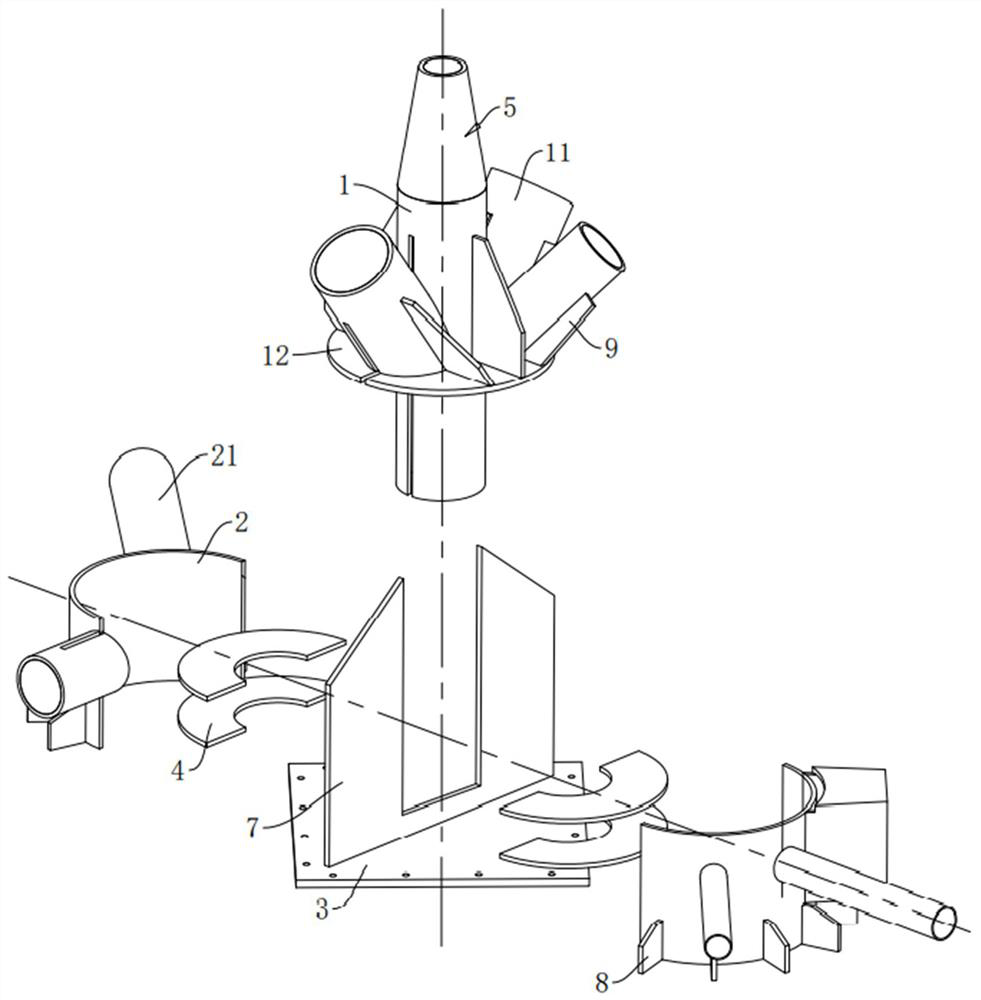

[0046] Attached to the following Figure 1-8 This application will be described in further detail.

[0047] The embodiment of the present application discloses a support node of a large-span V-shaped truss structure system. refer to figure 1 , the support node includes an upper main support rod 1, the center line of the upper main support rod 1 is arranged in the vertical direction; a plurality of first support pipes 11 are fixed on the upper main support rod 1, and the first support pipes 11 go from top to bottom It is arranged obliquely downward, and the centerlines of the plurality of first support tubes 11 meet to a point on the axis of the upper main support rod 1 . A support ring 12 is sleeved on the outer side of the upper main support rod 1, and the support ring 12 is fixedly connected with the outer side wall of the upper main support rod 1; a lower main support rod 2 is arranged below the upper main support rod 1, and the outer diameter of the support ring 12 is la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com