Mining anti-pulling high-strength round chain

An anti-pull, high-strength technology, applied in the field of circular chains, can solve the problem of difficulty in ensuring the overall strength of the chain, and achieve the effect of increasing strength and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

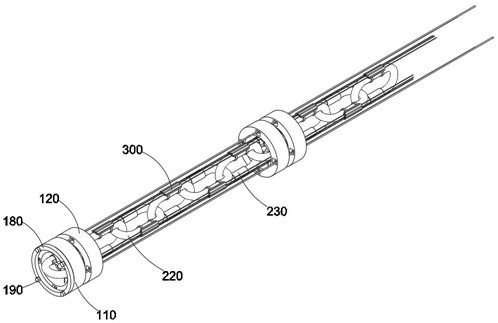

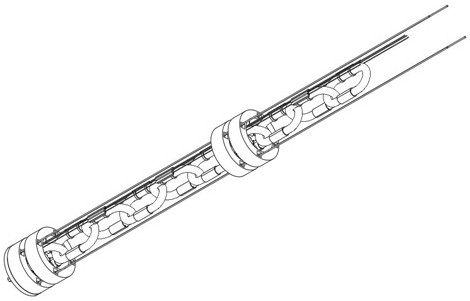

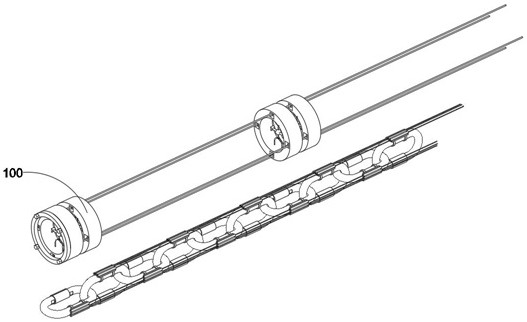

combine Figure 4 , 5 , 7, 8 and 9, the present invention provides a high-strength anti-pull circular chain for mining, including an external reinforcement mechanism 100, a reinforcement circular chain mechanism 200 and a toughness tension mechanism 300, wherein the reinforcement circular chain mechanism 200 is located at Inside the external reinforcement mechanism 100 , in addition, the toughness tensile mechanism 300 is installed on the reinforcement circular chain mechanism 200 .

[0035] The external reinforcement mechanism 100 includes a main washer 110 , an auxiliary washer 120 , a fixed pulley 130 , a fixing member 140 , a spring 150 , an insert 160 , a wire 170 , a ring 180 and a fixing nut 190 , and the reinforcing circular chain mechanism 200 includes a node chain The ring 210 , the auxiliary link 220 and the anti-pull assembly 230 , and the anti-pull assembly 230 further includes an outer cylinder 231 , a screw 232 , a sealing block 233 , a limit washer 234 and a ri...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com