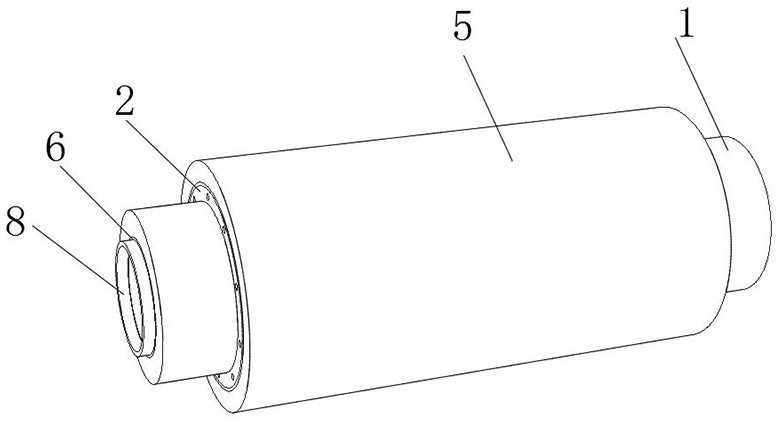

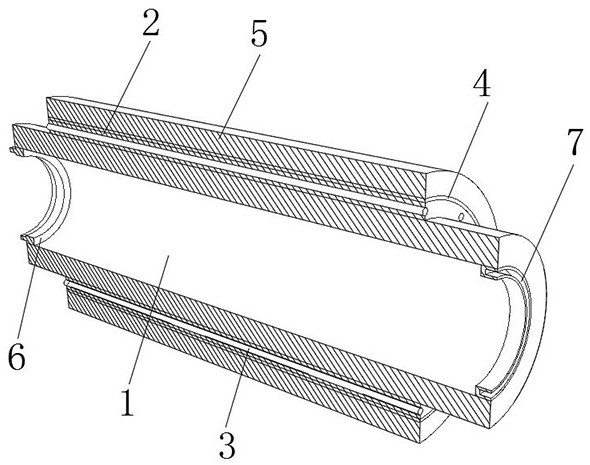

Low-temperature-resistant anti-cracking sprayed and wound thermal insulation pipe and manufacturing method thereof

A production method and anti-cracking technology, applied in the direction of heat preservation, pipe protection through heat insulation, pipe protection, etc., can solve problems such as surface cracking of heat preservation pipes, decline in heat preservation effect of heat preservation pipes, and easy detachment of heat preservation layers, so as to improve heat preservation effect, Effect of reducing cracking, strengthening elongation at break and tensile yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

This example provides a method for making a low-temperature-resistant and anti-cracking spray-wound insulation pipe, comprising the following raw materials in parts by weight: 100 parts of combined polyether, 100 parts of surfactant, 50 parts of catalyst, 80 parts of water, 200 parts of water Polyethylene granules, 70 parts of curing agent, 50 parts of accelerator, 80 parts of toughening agent, 50 parts of plasticizer, 80 parts of thickener, 60 parts of diluent and 100 parts of preservative, weigh the combined polyether, The surfactant and the catalyst are mixed, and the semi-prepolymer is obtained after mixing, the polyethylene particles are put into the grinder, the grinder is started, and the polyethylene particles are ground into a particle diameter of 400 mesh, polyethylene powder, curing agent, accelerator Put the agent, toughening agent, plasticizer, thickener, diluent and preservative into the mixer, start the mixer, fully stir the mixture in the mixer to obtain a polyet...

Embodiment 2

This example provides a method for making a low-temperature-resistant and anti-cracking spray-wound insulation pipe, comprising the following raw materials in parts by weight: 150 parts of combined polyether, 120 parts of surfactant, 80 parts of catalyst, 70 parts of clean water, 150 parts of water Polyethylene granules, 60 parts of curing agent, 90 parts of accelerator, 140 parts of toughening agent, 60 parts of plasticizer, 70 parts of thickener, 60 parts of diluent and 80 parts of preservative, weigh the combined polyether, The surfactant and the catalyst are mixed, and the semi-prepolymer is obtained after mixing, the polyethylene particles are put into the grinder, the grinder is started, and the polyethylene particles are ground into a particle diameter of 400 mesh, polyethylene powder, curing agent, accelerator Put the agent, toughening agent, plasticizer, thickener, diluent and preservative into the mixer, start the mixer, fully stir the mixture in the mixer to obtain a ...

Embodiment 3

This example provides a method for making a low-temperature-resistant and anti-cracking spray-wound insulation pipe, comprising the following raw materials in parts by weight: 130 parts of combined polyether, 150 parts of surfactant, 50 parts of catalyst, 60 parts of water, 170 parts of water Polyethylene granules, 70 parts of curing agent, 90 parts of accelerator, 110 parts of toughening agent, 90 parts of plasticizer, 60 parts of thickener, 55 parts of diluent and 30 parts of preservative, weigh the combined polyether, The surfactant and the catalyst are mixed, and the semi-prepolymer is obtained after mixing, the polyethylene particles are put into the grinder, the grinder is started, and the polyethylene particles are ground into a particle diameter of 400 mesh, polyethylene powder, curing agent, accelerator Put the agent, toughening agent, plasticizer, thickener, diluent and preservative into the mixer, start the mixer, fully stir the mixture in the mixer to obtain a polyet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap