Elevator steel belt wheel bearing test system

A technology of bearing test and elevator steel, which is applied in the direction of mechanical bearing test, etc., can solve the problems of lack of special equipment, etc., and achieve the effect of reducing operation burden, improving test efficiency and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are figure 1 For the reference direction:

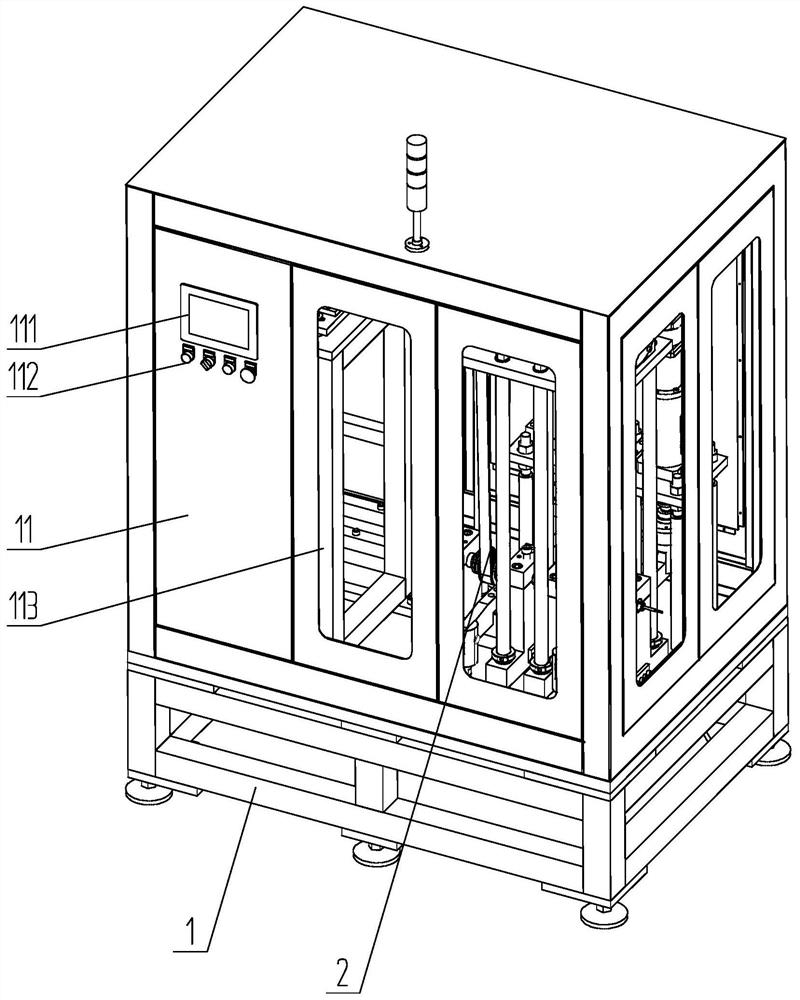

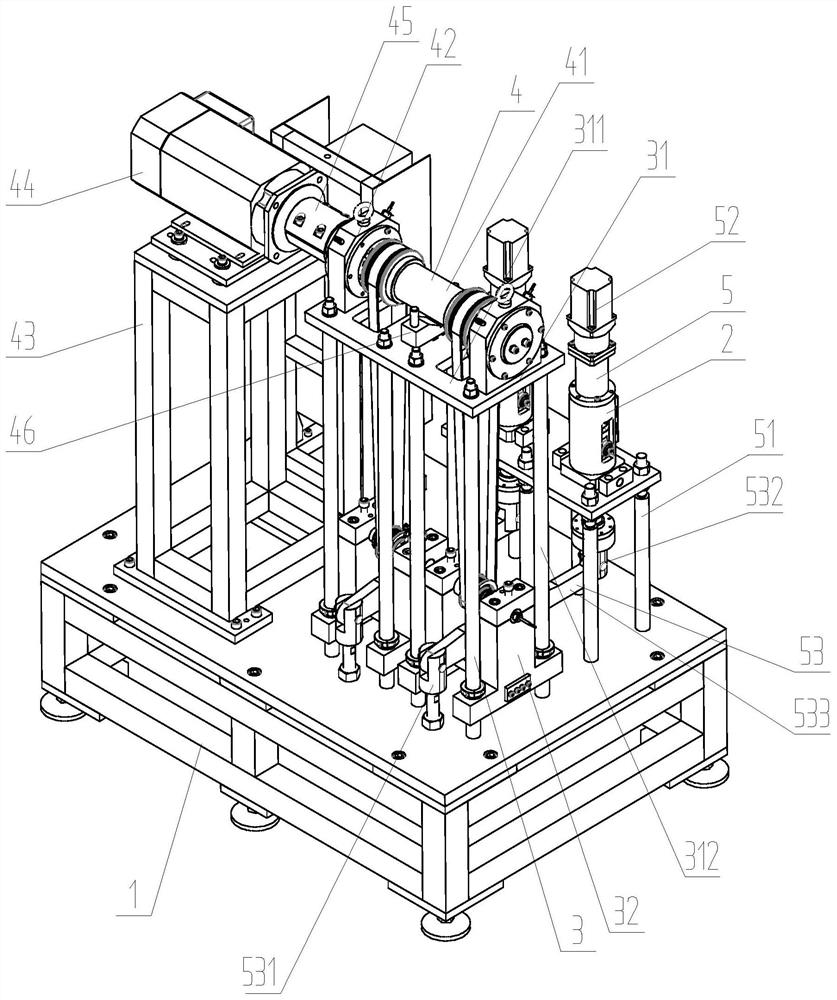

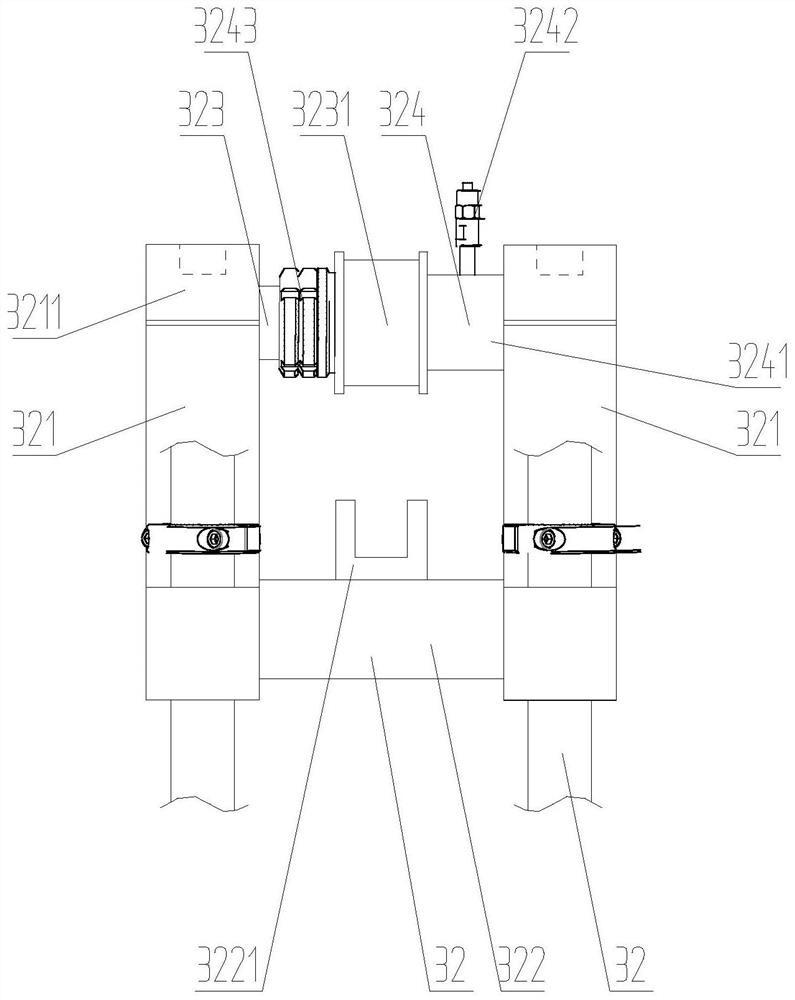

[0025] like Figure 1 to Figure 7 As shown, an elevator steel pulley bearing test system includes an equipment chassis 1, a bearing test device 2, the bearing test device 2 is installed on the equipment chassis 1, and adjustable support feet are installed at the bottom of the equipment chassis 1 to ensure that the experimental equipment The reliability test of the steel belt bearing is a destructive life test. The final result of the experiment is likely to be damaged to the bearing or the steel belt. When the bearing or the steel belt is damaged, there may be debris splashing. Therefore, , The outer cover of the bearing test device 2 is equipped with a protective cover 11. The protective cover 11 can effectively prevent the fragments from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com